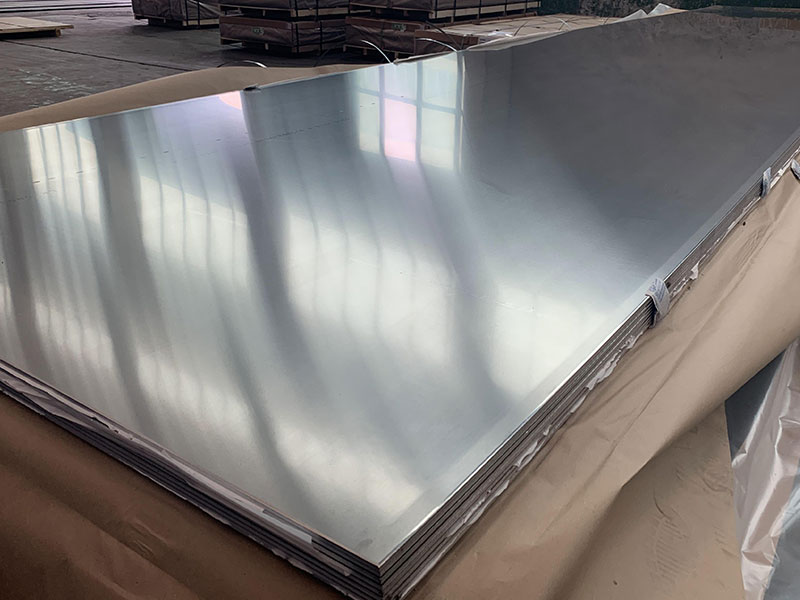

5083 marine aluminum sheet plate

5083 marine aluminum sheet plate has established itself as a standard reference in the maritime industry, thanks to its exceptional combination of performance, versatility, and durability.

5083 Aluminum Alloy was developed specifically for marine applications, showcasing remarkable resistance to corrosion inflicted by salty environments, while retaining strength at elevated temperatures. Its favorable mechanical properties make it the go-to choice for constructing marine vessels, including large yachts, military patrol boats, and offshore structures.

Technical Specifications and Parameters

| Technical Parameter | Details |

|---|---|

| Alloy Number | 5083 |

| Primary Alloying Elements | Magnesium (4.0-4.9%), Manganese (0.4-1.0%) |

| Temper Designations | H321, H116, H112 |

| Thickness | 1.0mm to 300mm |

| Width | Up to 2600mm |

| Length | Customizable from productionpliances |

| Ultimate Tensile Strength | 310 MPa (min) |

| Yield Strength | 230 MPa (min) |

| Elongation | 8-13% (depending on thickness) |

| Density | 2.68 g/cm³ |

Implementation Standards

The production of 5083 marine aluminum follows rigorous implementation standards, including recognition by various international marine organizations. Generally, the following standards govern its application:

- American Bureau of Shipping (ABS)

- Lloyd’s Register of Shipping (LR)

- Det Norske Veritas (DNV)

- United States Coast Guard (USCG)

Engineers and manufacturers must comply with these regulations to ensure a secured production process, which further enhances the integrity of the hull and several other pertinent elements of a vessel.

Alloy Tempering and Conditions

The mechanical properties of 5083 vary significantly based on tempering processes. The three primary temper mental designations pertinent to marine structures include:

- H116: Commonly used when a significant watershed needs are present; designed for optimal welding and excellent strength.

- H112: Usually for rolled plates with limited mechanical-strength requirements.

- H321: Employed for work require advanced hardness, put less stresses into used combined plate.

Correct temper processing not only strengthens the landing paths in manufacturing but also strategically prepares the product for heavy-duty use in extreme marine environments.

Chemical Properties

the specific chemical properties of 5083 marine aluminum enhances facility engineers' knowledge of material superiority. Another admired characteristic of 5083 is its resistance to pitting corrosion due to halide ions:

| Chemical Composition | Percentage |

|---|---|

| Aluminum (Al) | Balance |

| Silicon (Si) | 0.4% (max) |

| Iron (Fe) | 0.10% (max) |

| Copper (Cu) | 0.10% (max) |

| Manganese (Mn) | 0.4-1.0% |

| Magnesium (Mg) | 4.0–4.9% |

Applications

The distinct properties of 5083 marine aluminum platings highlight various parts it is regularly implemented in marine structures:

- Haulf Plates: Designed specifically for vessels' external structures to endure the harsh load-bearing of the seaworthiness activities.

- Bulkheads and Internal Fittings: Benefiting from dimensional integrity, versed with flat surfaces capable fully matched for prefabrication.

- Deck Systems: Often utilized for improved frame systems in massive scansnel deficits.

- Propecia Yachts: The preferable alloy connotation really encapsulates providing successive design aesthetics.

- Broader Construction Runs: Enjoy general everyday commercial industry with contour limitations permitted via hole redux adjusting.

Related Products

Marine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsRelated Blog

Marine 5083 5086 H116 Checkered Aluminum Plate for Deck Board

Premium Marine 5083/5086 H116 Checkered Aluminum Plate designed for deck boards. Boasting exceptional corrosion resistance, high strength, and durability, it meets marine industry standards for optimal performance in harsh sea environments.

View Details5083 marine grade aluminium plate

When it comes to marine construction and applications necessitating optimal performance in corrosive saltwater environments, 5083 marine grade aluminium plate stands out as one of the most reliable and versatile materials.

View Details5083 H116 marine grade aluminum alloy sheet plate

Superior corrosion resistance and high strength of 5083 H116 marine grade aluminum alloy sheet plate. Ideal for shipbuilding and marine structures, this alloy ensures durability in harsh sea conditions with excellent weldability and excellent workability.

View Details5083 0.5mm aluminum plate sheet for marine

5083 0.5mm aluminum plate sheet is a thin, high-strength marine-grade alloy offering excellent corrosion resistance, good weldability, and superior formability. Ideal for shipbuilding, boat decking, marine fittings, and coastal structures.

View DetailsMarine Aluminum Alloy Plate 5052 5083 6061

Marine environments pose extreme challenges—constant exposure to saltwater corrosion, mechanical stresses, and environmental fluctuations demand materials that combine strength, durability, and corrosion resistance.

View DetailsMarine grade aluminium alloy plate 5083 h116 with dnv certification

Marine grade aluminium alloy plate 5083 H116 with DNV certification is a high-strength, corrosion-resistant aluminum alloy plate specifically tailored for shipbuilding and offshore applications.

View Details

Leave a Message