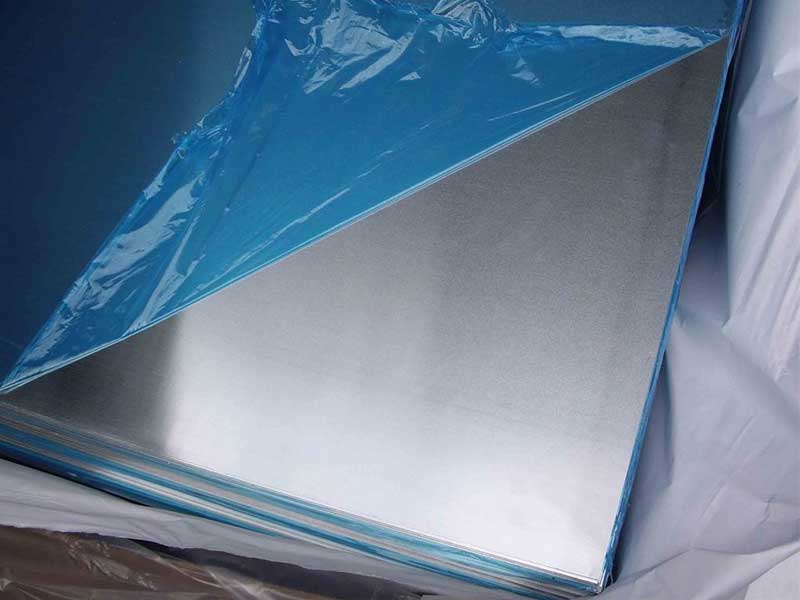

Marine aluminum plate 5005,5052 color coated

The Versatility of Marine Aluminum Plate 5005 and 5052: Beyond the Surface

Marine aluminum plates are crucial materials in various maritime applications, offering a unique blend of structural integrity, corrosion resistance, and aesthetic appeal. Among the popular alloy choices, the Marine Aluminum Plate 5005 and 5052, especially when color-coated, stand at the forefront.

What Sets 5005 and 5052 Apart?

Both the Marine Aluminum Plates 5005 and 5052 are recognized for their excellent anodizing and paintability. Their structural advantages can be attributed to their unique alloy strength and temperature responsiveness, making them suitable for a plethora of specialized marine applications.

Marine Aluminum Plate 5005: Known for its excellent weldability and moderate-to-high strength, 5005 typically features a significantly aesthetic appeal when coated with various colors. This alloy sustains good corrosion resistance, reinforcing its utilization in surfaces that might encounter salty marine environments.

Marine Aluminum Plate 5052: Renowned for its extraordinary resistance to corrosion and fatigue, the 5052 aluminum series exhibits unmatched durability. This alloy is often employed when exceptional strength is required without an increase in weight -- making it suitable for structural and external surfaces adjacent to water bodies.

Technical Specifications of Aluminuim Plates 5005 and 5052

Chemical Properties

| Alloy Number | Al (%) | Mg (%) | Si (%) | Cu (%) | Mn (%) | Fe (%) |

|---|---|---|---|---|---|---|

| 5005 | 94.7 min | 0.50-1.0 | 0.40 max | 0.1 min | 0.20 max | 0.70 max |

| 5052 | 93.5 min | 2.2-2.8 | 0.25 max | 0.10 max | 0.20-0.8 | 0.40 max |

Parameters

- Thickness Range (IN spanning mm): 3mm - 300mm

- Width Span: Up to 2500mm

- Length: Customized sheets available, generally spans to about 12,000mm

- Heat Treatment: Not heat-treated but can be strengthened with cold compressive processes.

ASTM Standards Compliance

- AMS QQ-A-250/9 (For 5005)

- AMS QQ-A-250/18 (For 5052)

- ASTM B221 – Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes for Use in Manufacturing.

these properties should inspire users’ decisions, focusing on how they deeply contribute to functionality and practicality.

Fusion of Functionality and Aesthetics

The ability of 5005 and 5052 aluminum plates to be color coated goes beyond the surface level. The colored finishes provide an aesthetic quality; they also add an additional protective layer, enhancing durability against saltwater infiltration, UV light degradation, and surface wear. Popular coatings often include polyurethanes, epoxies, or metallic finishes aimed at UV stability and gloss retention.

Applications of Marine Aluminum Plates 5005 and 5052

The versatility of the 5005 and 5052 marine aluminum plates places them in a variety of vital maritime applications:

Boat Building and Yacht Construction: Their lightweight and malleability contribute significantly to the motorboat and yachting industry to reduce overall boat weight while enhancing speed and fuel efficiency.

Shipyard General Fabrication: With high resistance to maritime atmospheres, marine aluminum plates are preferred for pontoons, barges, and ship burgees that require maintenance at dock yards.

Harbor and Aquarium Structures: Their various aesthetic appealing finish options allow for construction above or below the aquatic environments where saltwater penetration and corrosion are high risk.

Marine Infrastructure: Features such as jetties and commercial grade platforms texture remain operable against marine enunciations, contributing to structural soundness painted with aesthetically hardened capping layers.

Related Products

Marine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsRelated Blog

Marine aluminum plate 5005 5052 color coated

In the marine industry, where reliability meets aesthetics, Aluminum Plate 5005 and 5052 color coated options have taken the forefront as building materials. With undeniably strength, corrosion resistance, and a visually appealing surface.

View DetailsMarine aluminum plate 5005,5052 color coated

The Versatility of Marine Aluminum Plate 5005 and 5052: Beyond the SurfaceMarine aluminum plates are crucial materials in various maritime applications, offering a unique blend of structural integrity, corrosion resistance, and aesthetic appeal.

View Details

Leave a Message