5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

Table of contents

- Overview and advantages

- Typical applications on offshore oil & gas platforms

- Alloy designation and temper states

- Chemical composition

- Mechanical and physical properties

- technical specifications and manufacturing standards

- Corrosion resistance and welding/fabrication notes

- Design & implementation considerations

- Inspection, testing and quality control

5083 is an Al–Mg–Mn alloy (Aluminum 5xxx series) known for:

- High strength among non-heat-treatable aluminum alloys (strength improved by cold work).

- Excellent resistance to seawater and marine atmosphere corrosion — critical for offshore service.

- Good weldability with minimal post-weld strength loss when properly handled.

- Good formability and fatigue resistance for structural members.

- Good fracture toughness, even at sub-zero temperatures.

These properties make 5083 tubes an attractive choice for primary and secondary structural elements on offshore platforms such as riser supports, bracing, handrails, skid frames, piping supports, and modular deck systems.

Typical applications on offshore oil & gas platforms

- Structural columns and piles (where tube sections are advantageous)

- Bracing members and lattice work in topside and jacket structures

- Jacket and platform internals: walkways, handrails and ladders

- Tubular riser guides, supports and protective covers

- Buoyancy canisters and fairings (where welded tube assemblies are used)

- External piping support frames and skid bases

- Corrosion-resistant frames in splash zones and topsides

- Offshore living quarters and helideck framing where weight saving is valuable

5083 tubes are especially preferred in splash zone and immersed components because their Mg content confers excellent resistance to chloride-induced corrosion.

Alloy designation and temper states

Common alloy and temper combinations for 5083 tubes:

| Alloy | Common tempers | Description |

|---|---|---|

| 5083 | O, H111, H116, H321, H32 | O = annealed (maximum ductility, lower strength). H11/H111 = strain-hardened (minor). H116 = strain-hardened and stabilized for improved corrosion resistance. H321/H32 = strain-hardened and partially annealed/stabilized for improved toughness. |

Notes:

- H116 is commonly specified for marine and offshore applications due to its superior corrosion performance in seawater environments.

- H32 and H321 are used when higher strength and toughness are required after forming/welding.

Chemical composition

Typical chemical composition for 5083 (percent by mass), per common standards (EN, ASTM):

| Element | Typical range (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | 0.4 (max) |

| Silicon (Si) | 0.4 (max) |

| Copper (Cu) | 0.1 (max) |

| Zinc (Zn) | 0.25 (max) |

| Titanium (Ti) | 0.15 (max) |

| Others (each) | 0.05 (max) |

| Others (total) | 0.15 (max) |

(Always confirm against the specific procurement standard or material certificate for contract-specified limits.)

Mechanical and physical properties

Values depend on temper and product form (tube, plate, extrusion). Typical properties for 5083-H116/H321 tubes used in offshore structures:

| Property | Typical value |

|---|---|

| Density | 2.66 g/cm³ |

| Elastic modulus (Young’s modulus) | ~70 GPa |

| Thermal conductivity (20°C) | ~130 – 140 W/m·K |

| Coefficient of thermal expansion (20–100°C) | 23.8 × 10⁻⁶ /°C |

| Electrical resistivity (20°C) | ~0.035 Ω·mm²/m |

| Yield strength (Rp0.2) H116 | 215 – 255 MPa (varies with thickness) |

| Ultimate tensile strength (Rm) H116 | 305 – 350 MPa |

| Elongation at break (A) H116 | ≥ 8 – 12% (depends on thickness) |

| Hardness (Brinell) | ~70 – 90 HB (varies by temper) |

| Fatigue strength | Good — depends on geometry, surface finish, and welds |

Note: Thinner tube walls and specific tempers can change yield/ultimate values. Use supplier’s mill certificates for exact numbers for design calculations.

technical specifications and manufacturing standards

Common standards for 5083 aluminum tubes and tubular sections used offshore:

| Application / Aspect | Typical standards |

|---|---|

| Material specification | ASTM B221 (extruded), ASTM B241/B241M (seamless tubing - general), EN 754-2 / EN AW-5083 |

| Offshore structural aluminum | DNVGL-ST-0126 / DNV-OS-C101 (for structural use and welding rules) |

| Welding qualifications | AWS D1.2 / ISO 15614 (welding procedure qual.) |

| Corrosion testing | ASTM B117 (salt spray), ISO 9227 |

| Chemical composition & mechanical properties | EN 573 / EN 485 / ASTM B209 (plates/extrusions) |

| NDT & inspection | ASTM E165 (liquid penetrant), ASTM E580 (ultrasonic) |

| Heat treatment/temper control | EN 754 / ASTM specifications for temper |

Note: Exact standard selection depends on whether the tube is extruded or seamless, application (structural vs. piping), and client specifications (class society: DNV, ABS, etc.). For platform structural members, class society approval and welding procedures per DNV/ABS guidelines are typically required.

Alloy tempering conditions and heat treatment

5083 is a non-heat-treatable alloy; strengthening is achieved primarily by cold work. Common temper processes:

| Temper | Process description | Typical use |

|---|---|---|

| O (annealed) | Fully annealed for max ductility; solution heat-treated not applicable (non-heat-treatable) | Forming operations requiring maximum plasticity |

| H111 / H11 | Slight strain hardening (controlled) | Moderate strength with formability |

| H116 | Strain-hardened and stabilized for superior corrosion resistance | Offshore marine environments (preferred) |

| H32 / H321 | Strain-hardened to specified degree and stabilized by mild thermal treatment | Higher strength, good toughness after forming/welding |

Stabilization treatments (H116/H321) reduce susceptibility to intergranular corrosion by controlling Mg distribution and reducing risks associated with welding in seawater conditions.

Corrosion resistance and behavior in marine environments

- 5083 has excellent resistance to seawater, splash zone and atmospheric marine corrosion due to its high Mg content.

- It resists pitting and stress-corrosion cracking better than many other aluminum alloys, especially when properly stabilized (H116).

- Avoid exposure to strongly acidic or highly alkaline environments and avoid contact with dissimilar metals without insulating barriers (to prevent galvanic corrosion).

- Surface finishes (anodizing, conversion coatings) and sacrificial corrosion protection (paint systems, cathodic protection) can further extend life depending on exposure severity.

Welding, fabrication and joining

Welding is a primary fabrication method for tube assemblies on platforms.

Guidelines:

- Common welding processes: Gas Metal Arc Welding (GMAW/MIG), Gas Tungsten Arc Welding (GTAW/TIG), Pulsed GMAW, and submerged arc (for some fittings). Friction stir welding (FSW) may be used for certain joints.

- Use filler wires compatible with 5083 (e.g., ER5356, ER5183) depending on desired properties and corrosion resistance. ER5183 provides good strength and corrosion resistance in seawater.

- Pre-weld cleaning is critical: remove oil, grease, oxides and salts.

- Avoid overheating; maintain appropriate interpass temperatures and control heat input to mitigate softening in the weld zone.

- Post-weld treatment: mechanical stress-relief or controlled natural aging and possibly protective coatings. Note that 5083 cannot be strengthened by heat treatment — but temper selection and post-weld stabilization (e.g., H321/H116) assist performance.

- Perform qualified welding procedures and welder qualifications per applicable standards (AWS/ISO/DNV).

Typical filler and weld properties:

| Filler alloy | Typical use | Notes |

|---|---|---|

| ER5356 | General weld filler for Mg-bearing alloys | Good strength, common in 5xxx series; care with hydrogen porosity |

| ER5183 | Improved corrosion resistance | Often used for marine applications; good combination of strength and seawater resistance |

Design & implementation considerations

- Load-bearing design: Use mill-certified mechanical properties for the specific temper and wall thickness. Consider buckling, compression and fatigue under cyclic wave/operational loads.

- Wall thickness and diameter selection: Balance between weight savings and stiffness. For offshore, thicker walls and heavier tempers (H321/H32) may be chosen for primary members.

- Connection design: Design joints to avoid stress concentrations and crevice corrosion. Use proper tolerances and alignment to enable welding or bolting with insulating gaskets where dissimilar metals are involved.

- Galvanic corrosion: Avoid direct contact with more noble metals (e.g., stainless steels) in seawater without isolation.

- Protective systems: In splash zone consider combined strategies — protective coatings, sacrificial anodes, cathodic protection and regular inspection.

Inspection, testing and quality control

Offshore structural tubes typically undergo comprehensive QC:

| Test / Inspection | Purpose |

|---|---|

| Chemical analysis (OES/ICP) | Verify alloy composition per specification |

| Mechanical testing | Tensile, yield, elongation to confirm properties |

| Dimensional inspection | OD, wall thickness, straightness, ovality |

| Non-destructive testing (NDT) | Ultrasonic for internal defects; dye penetrant or visual for surface flaws |

| Corrosion testing / salt spray | Evaluate coatings and material behavior |

| Weld NDT | Radiography, ultrasonic, dye-penetrant, visual for weld integrity |

| Mill certificates / traceability | Ensure batch traceability to purchaser and class society requirements |

Class societies (DNV, ABS, Lloyd’s) often require documented material traceability and may require factory inspection or witnessing.

Typical sizes and tolerances (example)

Note: Actual available dimensions depend on manufacturer (extruded or seamless tube). Typical ranges:

| OD (mm) | Wall thickness (mm) | Typical use |

|---|---|---|

| 25 – 50 | 1.5 – 3.0 | Handrails, small supports |

| 60 – 114 | 2.0 – 6.0 | Bracing, mid-size supports |

| 127 – 406 | 6.0 – 20.0 | Primary structural members, jacket tubes |

| >406 | Custom | Large jacket tubes, piles (often specialized fabrication) |

Tolerances: EN/ASTM standards specify OD and wall tolerances; verify supplier data sheet and order specification.

Lifecycle, maintenance and repair

- Regular inspection: Monitor for pitting, weld integrity, deformation and coating condition — especially in splash zone and immersion.

- Cleaning: Remove marine growth, salts and deposits that accelerate localized corrosion.

- Repairs: Aluminum repairs require qualified welders and approved WPS. Surface preparation and matching filler materials are essential. For fatigue cracks, use appropriate repair techniques (stop-drilling, welded patch, or sleeve) and revalidate via NDT and stress analysis.

- Recoating and cathodic protection may be scheduled as preventive maintenance.

| Item | Data (typical) |

|---|---|

| Alloy | 5083 (Al–Mg–Mn) |

| Typical Mg | 4.0 – 4.9% |

| Typical Mn | 0.4 – 1.0% |

| Common tempers | H116, H321, H32, O, H111 |

| Density | 2.66 g/cm³ |

| Yield strength (H116) | ~215–255 MPa |

| Tensile strength (H116) | ~305–350 MPa |

| Elongation (H116) | ~8–12% |

| Modulus of elasticity | ~70 GPa |

| Corrosion resistance | Excellent in seawater; splash zone resistant |

| Standards | ASTM B221, ASTM B241, EN 755/754, DNV/ABS class rules |

Specification checklist for procurement (recommended)

- Alloy and temper (e.g., 5083-H116)

- Product form (extruded tube or seamless tube)

- Outer diameter, wall thickness, length, tolerances

- Mechanical property requirements (yield, tensile, elongation)

- Chemical composition limits and required certificates

- Welding and filler metal guidance (qualified WPS, filler alloy)

- NDT and inspection requirements, including class society witnessing

- Coating, surface finish and packaging requirements for marine service

- Traceability: mill certificate, heat number, batch testing

- Delivery and storage instructions to avoid contamination

5083 marine aluminum tubes are a durable, corrosion-resistant and high-strength choice for many offshore oil and gas platform applications. Their combination of seawater performance, weldability and favorable strength-to-weight ratio make them ideal for structural members in jackets, topsides and auxiliary systems. Proper temper selection (H116/H321), qualified welding procedures, correct filler alloys, and rigorous inspection/testing are essential to realize the full benefits of 5083 tubes in demanding offshore environments.

When specifying 5083 tubes, always reference the exact standard and class society requirements relevant to your project, obtain complete mill certificates, and work with experienced fabricators familiar with marine aluminum practices to ensure long-term performance.

Related Products

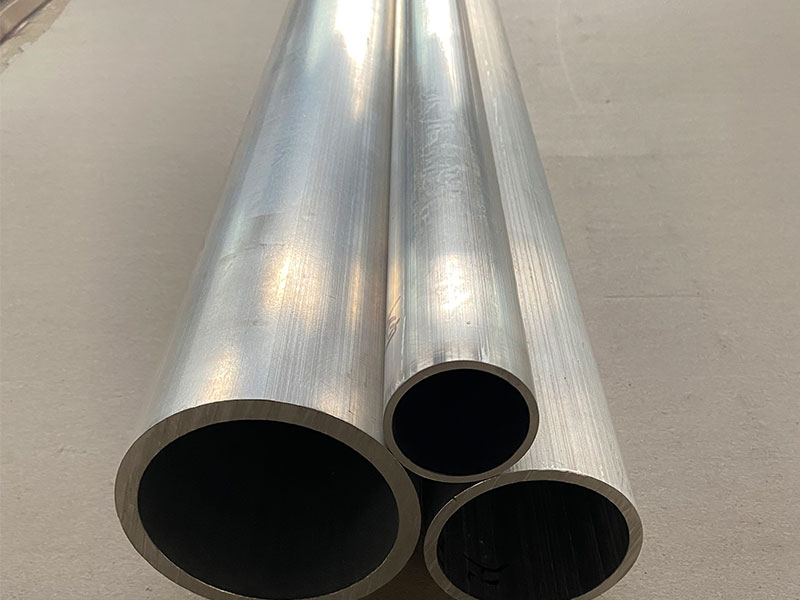

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

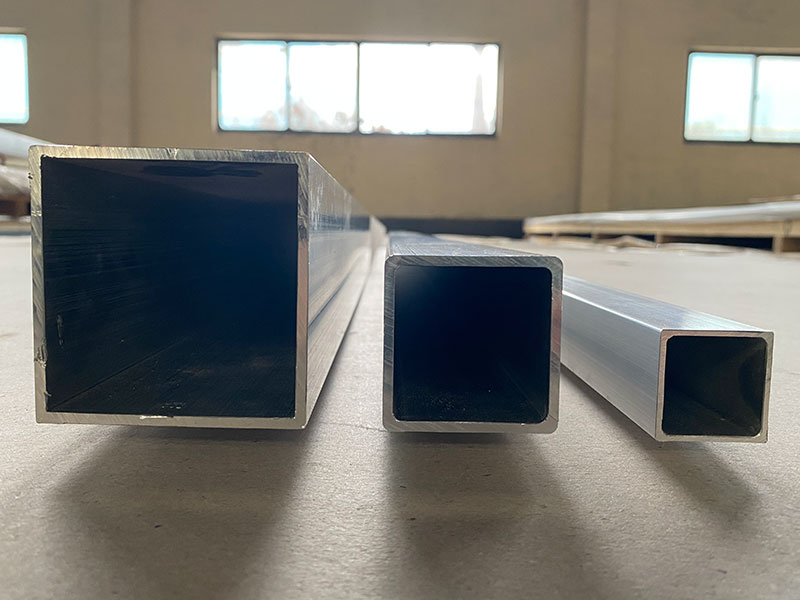

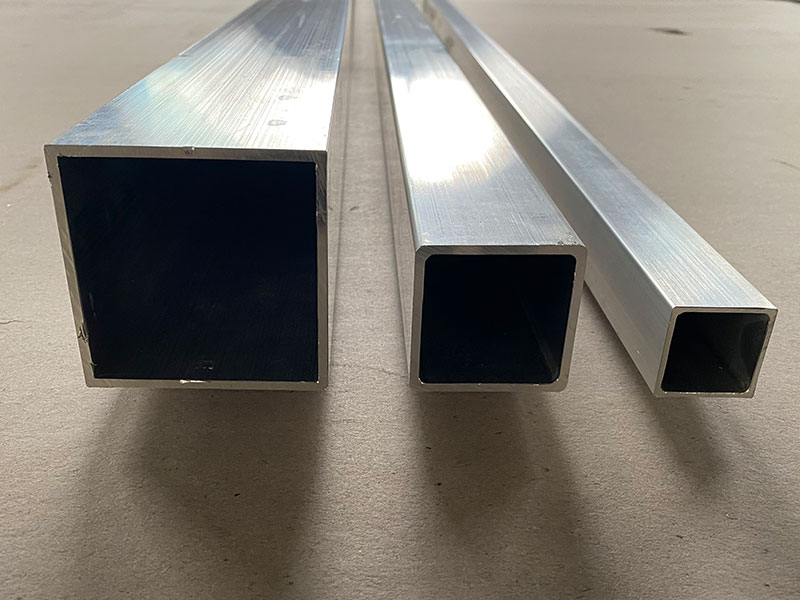

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details5083 Marine Aluminum Tubes for Marine Hull Construction

5083 aluminum alloy is one of the most widely used non-heat-treatable marine alloys. Designed for superior corrosion resistance, high strength, and excellent weldability, 5083 tubes are ideal for hull structures, superstructures, piping.

View Details

Leave a Message