Corrosion Resistant Aluminum Pipe Elbow for Offshore Platforms

In the challenging conditions of offshore platforms, where exposure to harsh saline water, high pressure, and fluctuating temperatures is constant, choosing the right piping components can make or break operational efficiency. Aluminum alloys are well-known for their corrosion resistance and mechanical strength, and when formed into pipe elbows, they play a crucial role in maintaining the structural integrity and flow reliability of offshore pipeline systems.

The Unique Corrosion Resistance Demanded by Offshore Pipeline Elbows

Offshore platforms subject pipeline elbows to continuous exposure to saltwater and marine weathering, creating aggressive conditions for standard metallic materials. Traditional carbon steel often requires additional coatings and sacrificial cathodic protection to withstand these attacks but still suffers from gradual deterioration.

Corrosion resistant aluminum alloys mitigate these issues through their intrinsic oxide film formation, creating a stable barrier against the ingress of chlorides and other corrosive agents. In addition, aluminum alloys' lightweight character reduces loading on platform supports—a consideration in offshore design.

Technical Parameters of Aluminum Pipe Elbows for Offshore Platforms

When selecting or fabricating aluminum pipe elbows for marine usage, certain technical characteristics ensure their suitability and longevity:

| Parameter | Specification |

|---|---|

| Material Alloy | 5052-H32 / 6061-T6 (common marine grade alloys) |

| Outer Diameter Range | 25 mm to 600 mm |

| Wall Thickness | 3mm to 20mm |

| Bend Radius | Typically 1.5D to 3D (D = pipe diameter) |

| Operating Temperature | -40°C to 150°C |

| Pressure Rating | Up to 25 MPa (depending on wall thickness and diameter) |

| Surface Treatment | Shot-blasting, anodizing, or powder coating for enhanced corrosion resistance |

Alloy Selection and Tempering: Meeting Marine Structural Needs

Among offshore-appropriate aluminum alloys, 5052-H32 and 6061-T6 terminate the list due to their adaptative properties:

5052-H32 provides excellent resistance to saltwater corrosion, modest strength (Yield Strength ~193 MPa), and excellent workability leading to ease in elbow forming. The "H32" temper indicates the alloy is strain-hardened and partially annealed, maintaining a favorable balance between forming ease and mechanical strength.

6061-T6 commonly used in more structural applications, offers higher mechanical strengths (Yield Strength ~275 MPa). The "T6" temper is a solution heat-treated and artificially aged state improving hardness and strength but requiring more precise control in forming operations to avoid cracking.

Careful temper selection ensures pipe elbows conform to pressures and stresses unique in offshore platforms while resisting micro-cracks caused by pipe system vibrations and environmental fatigue.

Implementation Standards and Compliance: Building Reliability at Sea

For offshore adaptation, aluminum pipe elbows must conform to internationally recognized shipbuilding and marine standards ensuring dimensional accuracy, pressure capability, and corrosion resistance:

- ASTM B241 and B687: Aluminum and aluminum-alloy pipe specifications for marine usage.

- ASME B16.9: Factory-made wrought steel but extended equivalency considerations apply to alloy elbows, covering dimensions and tolerances.

- API 2RD (API Specification 2RD): For mild steel elbows adapted by aluminum manufacturers as a model to meet offshore platform pipelining dimensions.

- NORSOK M-001 and ISO 13623: Offshore industry pipeline requirements, which underline corrosion allowance and durability.

Certification to these standards gives project engineers confidence in incorporating aluminum pipe elbows without downward effects on platform safety margins.

Chemical Composition and Corrosion Resistance Advantage

Chemical composition-tailored aluminum alloys excel in marine surroundings; see common aluminum marine pipe elbow alloys chemical profiles below:

| Element | 5052 Alloy (wt%) | 6061 Alloy (wt%) |

|---|---|---|

| Aluminum (Al) | Balance (~97.2%) | Balance (~97.9%) |

| Magnesium (Mg) | 2.2 – 2.8 | 0.8 – 1.2 |

| Silicon (Si) | 0.25 max | 0.4 – 0.8 |

| Iron (Fe) | 0.4 max | 0.7 max |

| Copper (Cu) | 0.1 max | 0.15 – 0.4 |

| Manganese (Mn) | 0.1 – 0.4 | 0.15 max |

| Chromium (Cr) | 0.15 – 0.35 | 0.04 – 0.35 |

| Zinc (Zn) | 0.1 max | 0.25 max |

Magnesium in the 5052 alloy particularly enhances saltwater resistance by creating a highly stable oxide passive layer, critical to the corrosion resistance essential on offshore platforms.

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

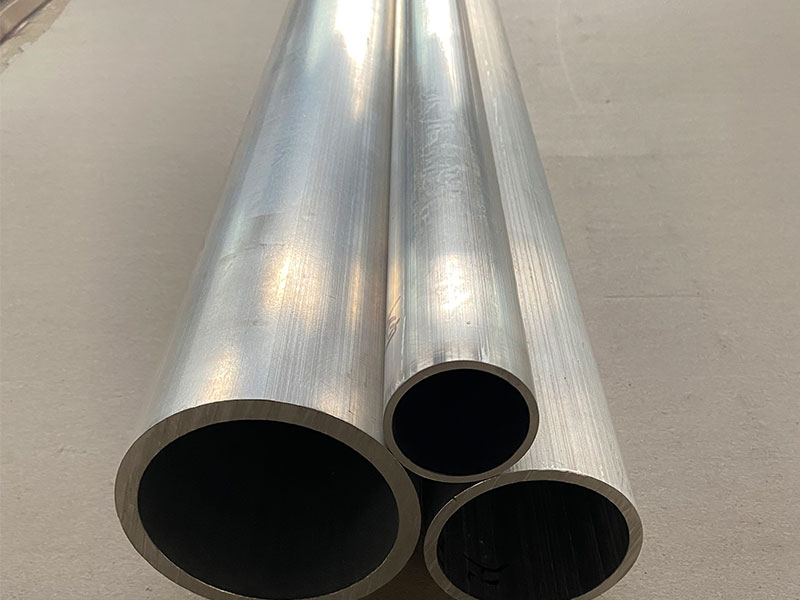

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

Aluminum Elbow for Marine Exhaust Systems

In marine engineering, ensuring durability, corrosion resistance, and optimal flow dynamics of exhaust components is crucial for the longevity and performance of onboard systems.

View DetailsMarine Aluminum Elbow for Offshore Oil Spill Containment Systems

Marine Aluminum Elbow for Offshore Oil Spill Containment Systems: Functions, Applications, and Technical InsightsIn the demanding and often harsh environment of offshore oil spill containment systems, every component requires superior performance.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View DetailsAluminum Elbow for High Pressure Saltwater Pipelines on Ships

In modern shipbuilding and marine engineering, the integrity and durability of high pressure saltwater pipelines stand as a critical priority.

View DetailsAluminum Elbow for Marine Water Purification Systems

Aluminum elbows are specialized pipe fittings designed to change the direction of flow in piping systems, commonly at 45°, 90°, or 180° angles. In marine water purification systems, t.

View Details

Leave a Message