Custom Marine Aluminum Elbow Fittings for Marine Industry

Custom marine aluminum elbow fittings are specialized pipe and tube fittings engineered for use in harsh marine environments. Designed to change the direction of fluid, air, or cable runs on vessels, offshore platforms, and coastal installations, these elbows combine corrosion resistance, high strength-to-weight ratio, and precise manufacturing tolerances to meet demanding marine specifications.

Table of Contents

- Product Overview

- Features

- Materials & Chemical Composition

- Mechanical Properties & Performance

- Technical Specifications

- Surface Finishes & Corrosion Protection

- Manufacturing & Quality Control

- Typical Applications & Use Cases

- Selection Guide & Installation Notes

- Maintenance & Lifetime Expectation

- Standards & Compliance

Aluminum elbow fittings for marine use are typically available in common angles (45°, 90°, 60°, 30°) and custom geometries. They are used in fluid, pneumatic, hydraulic, and cable routing systems where weight savings and corrosion resistance are critical. Common connection types include butt-weld, socket-weld, flared, compression, threaded (special coatings), and flanged ends.

Primary advantages:

- Excellent corrosion resistance in seawater (when appropriate alloys and finishes are used)

- Low density reducing overall vessel weight

- Good formability for custom geometries

- Non-magnetic grades available when required for sensitive equipment

Features

- High strength-to-weight ratio suitable for weight-sensitive marine structures

- Marine-grade aluminum alloys (e.g., 5083, 6061, 6063, 5086) selected based on application

- Custom angles and dimensions available to match system routing and space constraints

- Multiple end-connection options for integration into existing piping systems

- Surface treatments and anodizing to enhance corrosion protection

- Precision machining and tight dimensional tolerances for leak-free joints

- Compatibility with common joining methods: TIG/argon welding, mechanical fastening, and adhesives where applicable

Materials & Chemical Composition

Below are typical chemical compositions for commonly used marine aluminum alloys. Final composition for a custom fitting will depend on customer specification and applicable marine standards.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|

| 5083 | 0.4–1.0 | ≤0.4 | ≤0.1 | 0.4–1.0 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | Balance |

| 5086 | 0.4–1.0 | ≤0.5 | ≤0.1 | 0.2–1.0 | 3.5–4.5 | 0.05–0.25 | ≤0.25 | ≤0.15 | Balance |

| 6061 | 0.4–0.8 | ≤0.7 | 0.15–0.4 | 0.15–0.4 | 0.8–1.2 | 0.04–0.35 | 0.0–0.25 | 0.0–0.15 | Balance |

| 6063 | 0.2–0.6 | ≤0.35 | ≤0.1 | ≤0.15 | 0.45–0.9 | ≤0.1 | ≤0.1 | ≤0.1 | Balance |

Notes:

- "Balance" means remaining percentage is aluminum.

- Alloy selection should consider strength, weldability, and corrosion resistance required by the application.

Mechanical Properties & Performance

Typical mechanical properties for the listed alloys (representative values; depend on temper and processing):

| Property | 5083-H111 | 5086-H32 | 6061-T6 | 6063-T5 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 305–350 | 300–340 | 310–350 | 180–220 |

| Yield Strength (MPa) | 125–215 | 165–275 | 240–270 | 120–150 |

| Elongation (%) | 10–20 | 10–18 | 8–12 | 6–10 |

| Density (g/cm³) | 2.66 | 2.66 | 2.70 | 2.70 |

| Hardness (HB) | 55–75 | 60–85 | 90–110 | 40–70 |

Performance considerations:

- Fatigue resistance is important in vibrating environments; alloy temper and manufacturing method (wrought vs. cast) affect fatigue life.

- Welded joints should be specified with proper filler alloys and post-weld treatments to restore corrosion resistance and strength where required.

Technical Specifications

A table of typical dimensional and connection options and pressure/temperature capabilities. Actual ratings must be verified for the specific design and wall thickness.

| Parameter | Typical Range / Options |

|---|---|

| Standard Angles | 30°, 45°, 60°, 90°, custom angles |

| Pipe Sizes (OD) | 1/4" — 24" (6 mm — 600 mm), custom sizes available |

| Wall Thickness | Sch 10 to Sch XXS equivalent, custom thicknesses |

| Connection Types | Butt-weld, socket-weld, flared, compression, threaded (coated), flanged |

| Design Pressure | Up to 100 bar (dependent on size, wall thickness, and alloy) |

| Operating Temperature | -50°C to 150°C (depends on alloy & temper) |

| Typical Dimensional Tolerances | ±0.5 mm (custom tighter tolerances on request) |

| Surface Finish | As-machined, anodized, bead-blasted, polished, custom coatings |

| Certifiable Standards | ABS, DNV-GL, Lloyd's, ISO, ASTM (per alloy and fabrication method) |

Example pressure capability (illustrative, not guaranteed — verify by calculation):

| OD (mm) | Wall (mm) | Alloy | Approx Max Working Pressure (bar) |

|---|---|---|---|

| 50 | 3.0 | 6061 | 20–35 |

| 100 | 5.0 | 5083 | 20–40 |

| 200 | 8.0 | 5086 | 15–30 |

Surface Finishes & Corrosion Protection

Proper surface treatment extends service life in marine environments.

| Finish Type | Description | Typical Use |

|---|---|---|

| Mill/As-machined | No additional treatment | Temporary, indoor, or protected installations |

| Anodizing (Type II/III) | Electrochemical oxide layer for resistive and aesthetic properties | Highly corrosive areas, visible surfaces |

| Chromate conversion | Provides temporary corrosion protection and paint adhesion | Pre-painting, sacrificial protection |

| Powder coating | Durable, color-customizable protective layer | Aesthetic and corrosion protection above waterline |

| Epoxy/polyurethane paint | Thick protective coating systems | External hull and exposed piping systems |

| Cathodic protection (in system) | Sacrificial anodes or impressed current | Long-term immersion and submerged components |

Notes:

- Some finishes (e.g., anodizing) may not be recommended after welding; plan post-fabrication treatment.

- Use of dissimilar metals (steel flanges, stainless fasteners) requires isolation measures and careful selection to avoid galvanic corrosion.

Manufacturing & Quality Control

Production stages and QC steps typically include:

- Material certification and chemical analysis (material test reports, MTRs)

- Cutting, bending, or forging to desired geometry

- Machining of ends and sealing faces

- Welding (TIG/argon recommended for aluminum) with qualified weld procedures (WPS/PQR)

- Post-weld heat treatment or stress relief as needed

- Dimensional inspection and pressure testing (hydrostatic or pneumatic)

- Non-destructive examination (Dye penetrant for surface cracks; radiography for critical welds if required)

- Surface treatment and final QA inspection

- Packaging for marine transit (moisture barrier, desiccants, secure crating)

Quality documentation offered:

- MTRs, welding records (WPS/PQR), inspection reports, test certificates, NDT reports, and compliance certificates upon request.

Typical Applications & Use Cases

- Freshwater and seawater piping systems on ships and yachts (drainage, bilge, ballast)

- HVAC duct and pipe routing on vessels and offshore platforms

- Fuel and lubrication lines (specific alloys and treatments required)

- Compressed air and pneumatic systems where weight is critical

- Cable routing and conduit bends for electrical systems (non-magnetic grades as required)

- Fire suppression systems (compatibility with system fluids must be verified)

- Custom fabrications for superyachts, patrol boats, ferries, research vessels, and offshore installations

Example use-case scenarios:

- A 90° aluminum elbow (5083-H111) used in a seawater cooling circuit on a research vessel: welded fittings with chromate and epoxy coatings and cathodic protection to ensure long-term reliability.

- Lightweight HVAC elbow assemblies on a high-speed ferry using 6063-T5 extruded sections with flanged ends for modular replacement.

Selection Guide & Installation Notes

Selection checklist:

- Confirm fluid type, temperature, and pressure.

- Select alloy based on corrosion exposure, strength, and weldability.

- Choose appropriate connection type for system compatibility.

- Confirm required finishes and post-fabrication coatings.

- Verify compatibility with other materials to avoid galvanic corrosion.

- Request MTRs and welding qualifications for critical services.

Installation best practices:

- Use qualified welders and controlled welding procedures for aluminum.

- Preheat unnecessary — avoid overheating; use recommended filler alloys.

- Isolate dissimilar metals with dielectric barriers or non-conductive gaskets.

- Apply recommended torque values for threaded connections; use compatible sealants rated for marine use.

- Pressure test assemblies per project standards (hydrostatic preferred for leak detection).

Maintenance & Lifetime Expectation

- Routine inspections for corrosion, cracks around welds, and mechanical wear are recommended.

- Frequency: visual inspections monthly to quarterly for critical systems; full pressure tests annually or per classification society.

- Maintenance tasks include touch-up coatings, replacing sacrificial anodes, and re-torquing fasteners.

- Expected lifetime: 10–30+ years depending on alloy, environment, protective measures, and maintenance. Proper design and coatings significantly extend life in seawater exposure.

Standards & Compliance

Commonly referenced standards and classifications applicable to marine aluminum fittings:

- ASTM B209 (Aluminum and Aluminum-Alloy Sheet and Plate)

- ASTM B241 / B241M (Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Round Tube)

- ISO 6361, ISO 15590 (as applicable)

- ABS, DNV-GL, Lloyd’s Register — vessel and offshore component approvals may be required

- Welding standards: AWS D1.2 (Aluminum Welding), ISO 15614 series for WPS/PQR

Always confirm specific client and flag-state regulatory requirements.

Custom marine aluminum elbow fittings provide a lightweight, corrosion-resistant solution for a wide range of marine piping and routing needs. Selecting the correct alloy, finish, and connection style — combined with qualified fabrication and thorough QC — leads to long-lasting, reliable components suited for shipboard, offshore, and coastal infrastructure. When properly specified, these fittings deliver reduced vessel weight, excellent performance in corrosive environments, and flexibility for custom installations.

For custom quotes, drawings, tolerances, or to request material test reports and welding procedures for your application, please provide system fluid, pressure/temperature, connection types, required alloy, and quantity.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

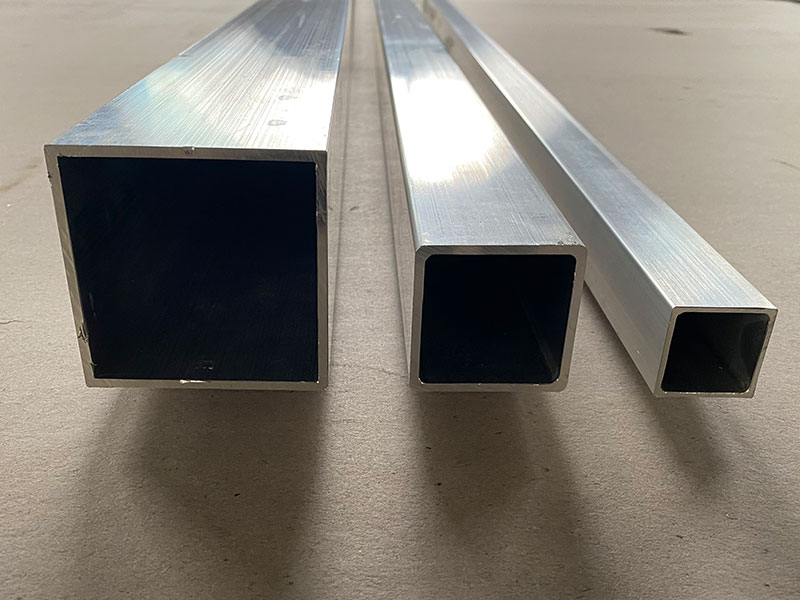

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

Marine Aluminum Pipe Elbow for High Flow Desalination Units

In the rapidly advancing realm of seawater desalination, marine aluminum pipe elbows play a pivotal role in ensuring the smooth and efficient operation of high flow desalination units.

View Details5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

View DetailsMarine Aluminum Elbow for Fuel System Installations

When it comes to designing and installing fuel systems in marine environments, using the right materials is paramount. Among these materials, Marine Aluminum Elbows is know due to their remarkable properties and advantages.

View DetailsLightweight Marine Aluminum Pipe Elbow for Boat Plumbing

A lightweight marine aluminum pipe elbow designed specifically for boat plumbing combines corrosion resistance, low weight, and structural integrity to meet the demanding conditions of marine environments.

View DetailsAluminum 5083 Marine Pipe Elbow for Ship Building Projects

Aluminum 5083 marine pipe elbows are essential fittings used in shipbuilding and maritime systems where strength, corrosion resistance, and lightweight construction are critical.

View DetailsAluminum Marine Elbow with High Corrosion Resistance

FeaturesHigh corrosion resistance compatible with seawater and brackish environmentsLightweight compared to steel or bronze fittings.

View Details

Leave a Message