Aluminum 5083 Marine Pipe Elbow for Ship Building Projects

Aluminum 5083 marine pipe elbows are essential fittings used in shipbuilding and maritime systems where strength, corrosion resistance, and lightweight construction are critical.

Aluminum 5083 is an aluminum–magnesium (Al–Mg) alloy known for excellent corrosion resistance in seawater, good weldability, and high strength after cold working. Pipe elbows made from 5083 are used to change fluid direction, connect piping runs of different orientations, and accommodate tight spaces aboard vessels. Typical functions include:

- Redirecting fluid flow (cooling water, bilge, ballast, fuel return lines, drain systems)

- Joining pipe sections in confined or complex geometries

- Providing corrosion-resistant transitions in seawater-exposed systems

- Serving in lightweight process piping where weight savings improve vessel performance

Advantages of 5083 pipe elbows for marine use:

- Outstanding resistance to seawater corrosion and stress-corrosion cracking

- High yield strength compared to pure aluminum grades

- Good weldability for field and factory fabrication

- Lightweight compared to steel, improving center-of-gravity and fuel efficiency

- Suitable for cryogenic temperatures (retains toughness)

Typical Applications in Shipbuilding

- Sea chest piping and sea water cooling circuits

- Ballast and bilge piping systems

- Deck drainage and scuppers

- HVAC and chilled water distribution on vessels and offshore platforms

- Fuel service (non-pressurised lines) and lube oil return lines (where allowed by code)

- Firewater distribution systems in some light-duty applications (verify standard)

- Pipe runs on aluminum superstructures, fast patrol craft, ferries, yachts, and offshore installations

Note: For high-pressure or hazardous fluid services, verify with classification society rules and consider alternative materials or additional testing.

Alloy Temper Conditions and Fabrication Notes

Aluminum 5083 is supplied in various tempers — commonly O, H111, and H116/H321 depending on required strength and stress-relief conditions. For marine pipe elbows, the temper affects forming, welding, and mechanical performance.

tempers:

- 5083-O: Annealed (maximum ductility). Easiest to form; lowest strength.

- 5083-H111: Slightly worked; commonly used for formed sections that need moderate strength.

- 5083-H116 / H321: Cold-worked or strain-hardened and stabilized for improved strength and stress-corrosion resistance (note: H116 is commonly referenced for 5083 in marine applications).

Forming and welding guidelines:

- Bending and elbow forming are typically done by hot or cold forming depending on elbow geometry and wall thickness. 5083 has good formability.

- Welding: Gas tungsten arc (GTAW/TIG) or gas metal arc (GMAW/MIG) are common. Use compatible filler alloys (e.g., 5183 or 5356) per code requirements. Preheat is generally not required; avoid excessive heat input to maintain mechanical properties.

- Post-weld: Strength in the weld zone may change; follow classification society requirements for post-weld treatment and NDT (dye-penetrant, ultrasonic, radiographic as applicable).

- Anodizing: Possible but may be unnecessary for marine corrosion resistance.

Chemical Composition

Typical chemical composition of Aluminum 5083 (% by weight). Note that exact limits vary by standard (e.g., ASTM B209/B221/B241, EN standards). Use manufacturer certificates for precise values.

| Element | Typical Range (wt%) | Notes |

|---|---|---|

| Al | Balance | Aluminum base |

| Mg | 4.0 – 4.9 | Primary alloying element for strength and corrosion resistance |

| Mn | 0.4 – 1.0 | Improves strength |

| Cr | 0.05 – 0.25 | Controls grain structure and improves corrosion resistance |

| Fe | ≤ 0.4 | Impurity |

| Si | ≤ 0.4 | Impurity |

| Zn | ≤ 0.25 | Impurity |

| Cu | ≤ 0.10 | Low to minimize susceptibility to corrosion |

| Ti | ≤ 0.15 | Trace, helps grain refinement |

| Others | Each ≤ 0.05; Total ≤ 0.15 | Residuals per standard |

(Verify composition to the applicable procurement standard or mill certificate.)

Mechanical Properties

Representative mechanical properties for 5083 in common tempers. Values differ by thickness and temper; confirm with supplier.

| Property | 5083-O (approx.) | 5083-H111 (approx.) | 5083-H116 / H321 (approx.) | Units |

|---|---|---|---|---|

| Tensile strength (Rm) | 210 – 240 | 260 – 300 | 290 – 330 | MPa |

| Yield strength (Rp0.2) | 55 – 80 | 120 – 230 | 215 – 280 | MPa |

| Elongation (A50) | 15 – 30 | 10 – 20 | 10 – 18 | % |

| Density | 2.66 | 2.66 | 2.66 | g/cm3 |

| Modulus of elasticity | 69 | 69 | 69 | GPa |

(Exact mechanical properties depend on product form, wall thickness, and processing. Use mill test reports for design.)

Corrosion Resistance and Performance in Seawater

- 5083 exhibits excellent resistance to general seawater corrosion and superior resistance to stress corrosion cracking (SCC) compared to many other high-strength aluminum alloys.

- Chromium and magnesium content improve pitting and crevice corrosion resistance.

- Regular inspection and maintenance (washdown, avoidance of dissimilar metal contact without insulation) will prolong service life.

- Galvanic corrosion: When in contact with more noble metals (e.g., copper, stainless steel) use dielectric isolation or sacrificial anodes; aluminum is anodic relative to many materials.

Implementation Standards and Codes

When specifying and fabricating Aluminum 5083 pipe elbows, consult the following commonly referenced standards and classification society rules:

- ASTM B241 / B241M — Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Bar

- ASTM B429 / B429M — Aluminum-Alloy Extruded Bars, Rods, and Wire

- ASME B31.3 / B31.1 — Process and power piping (use caution for shipboard systems; refer to marine codes)

- DNV, ABS, Lloyd's Register, Bureau Veritas — Classification society rules for aluminum structures and piping (each society has specific aluminum welding, testing, and design requirements)

- EN 573 / EN 485 series — Chemical composition and mechanical properties for aluminium and aluminium alloys

- ISO 6361 / ISO 209 — Aluminum alloy flat products and pipe standards (region-dependent)

- AWS D1.2 — Structural Welding Code–Aluminum (welding procedures and qualifications)

Always indicate the applicable standard in procurement documents and request mill certificates and weld procedure qualifications per the chosen code/class.

Dimensional and Pressure Considerations

Pipe elbows for marine piping are available in various schedules (wall thicknesses), radii (short radius LR = 1D, long radius LR = 1.5D), diameters, and fabrication methods (cold-bent, mandrel-bent, forged/extruded elbow, welded segmented elbow).

Examples of nominal dimensions and suitability (illustrative — confirm with supplier/manufacturer):

| Nominal Pipe Size (DN) | Typical OD (mm) | Typical Wall Thickness (mm) | Typical Radius | Common Use |

|---|---|---|---|---|

| DN25 (1") | 33.4 | 2.0 – 3.0 | 1D / 1.5D | Small service lines |

| DN50 (2") | 60.3 | 2.9 – 4.0 | 1D / 1.5D | Sea water cooling |

| DN100 (4") | 114.3 | 3.6 – 6.0 | 1D / 1.5D | Bilge / ballast |

| DN200 (8") | 219.1 | 6.0 – 12.0 | 1D / 1.5D | Large ballast / sea-chest |

Pressure ratings are a function of wall thickness, temperature, and joint/weld quality. Use design formulas per chosen piping code (ASME B31 or class rules) and consider corrosion allowance.

Welding and Joining Practices

Filler alloys and joint practice:

- Preferred fillers: 5183 (Al-Mg alloy) and 5356 are often used depending on service and classification society approval.

- Weld procedures should be qualified (PQR/WPQ) per AWS or classification rules.

- Use inert gas shielding (argon) for GTAW/TIG.

- Avoid contamination from oils, salts, and other foreign materials; clean surfaces before welding.

- For threaded connections: Avoid dissimilar metals or use coatings/dielectric bushings to prevent galvanic corrosion.

Testing:

- Visual inspection, dye-penetrant for surface defects

- Non-destructive testing (ultrasonic or radiographic) where specified by classification rules

- Mechanical testing per code for critical joints

Inspection, Maintenance and Service Life

- Regular inspections for pitting, crevice corrosion, and galvanic attack—especially at joints and fittings.

- Ensure sacrificial anodes are maintained in seawater systems where necessary.

- Avoid stagnant seawater pockets and ensure flow rates preclude sediment deposition (which can concentrate corrosive agents).

- Repair procedures: small localized damage can be welded or patched, but any repair must follow classification society-approved procedures.

Selection Checklist for Shipbuilding Engineers

- Confirm service fluid (sea water, fresh water, fuel, oil) and pressure/temperature range.

- Select correct temper and wall thickness for mechanical and corrosion demands.

- Specify classification society or project standard for welding, testing, and inspection.

- Specify filler alloy and welding qualifications.

- Ensure dielectric isolation from dissimilar metals or provide cathodic protection.

- Request mill test certificates (chemical and mechanical) and welding PQR/WPQ documentation.

- Define dimensional tolerances, elbow radius (1D/1.5D), and end preparation (butt-weld, socket weld, flanged).

| Item | Specification / Value |

|---|---|

| Material | Aluminum Alloy 5083 |

| Temper options | O, H111, H116 / H321 (specify) |

| Typical composition | Mg 4.0–4.9%, Mn 0.4–1.0%, Cr 0.05–0.25% (balance Al) |

| Density | 2.66 g/cm3 |

| Modulus | 69 GPa |

| Typical tensile strength | 210–330 MPa (depends on temper) |

| Common fillers | ER5183, ER5356 (per code) |

| Manufacturing methods | Extruded/forged, cold- or hot-formed, segmented welded |

| Standards | ASTM B241, AWS D1.2, DNV/ABS/LR/BV rules, EN/ISO equivalents |

| Corrosion resistance | Excellent in seawater; good SCC resistance |

| Typical applications | Sea water cooling, ballast, bilge, deck drainage, HVAC piping |

Related Products

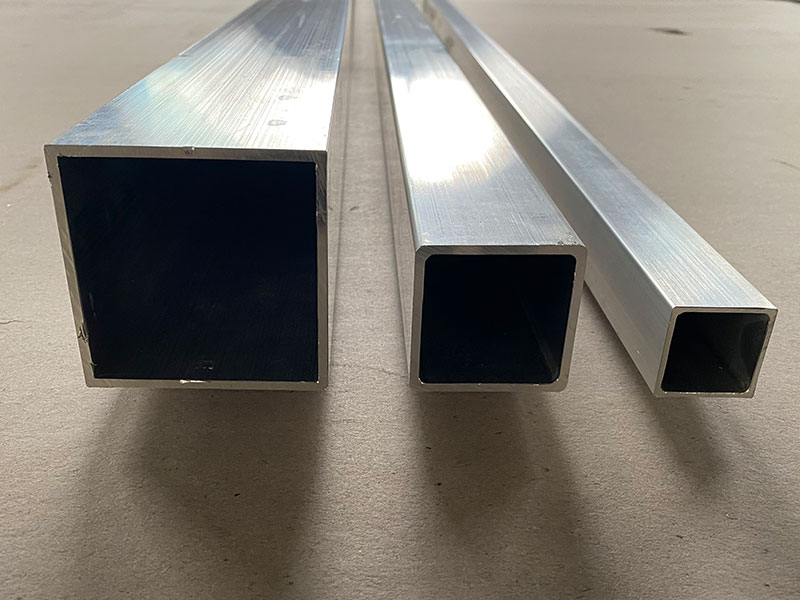

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

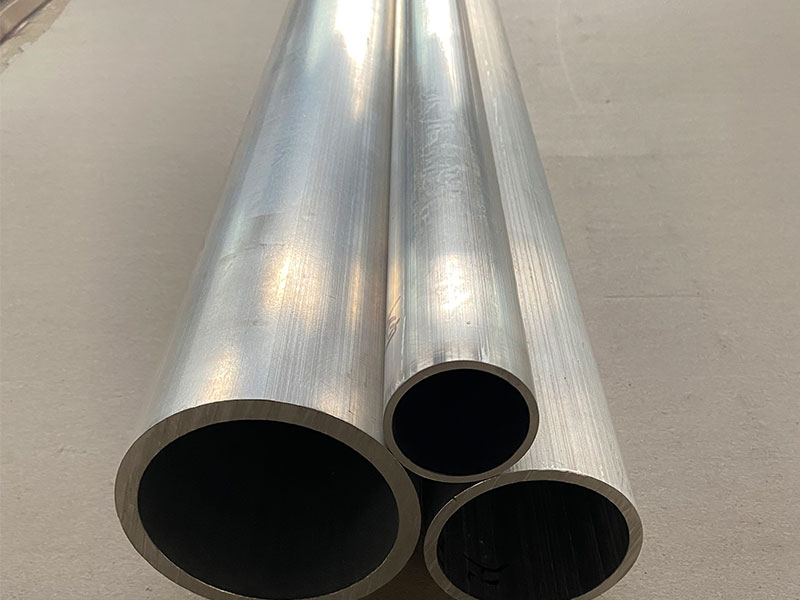

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details5083 Marine Aluminum Tubes for Marine Hull Construction

5083 aluminum alloy is one of the most widely used non-heat-treatable marine alloys. Designed for superior corrosion resistance, high strength, and excellent weldability, 5083 tubes are ideal for hull structures, superstructures, piping.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View DetailsAluminum 5083 Marine Pipe Elbow for Ship Building Projects

Aluminum 5083 marine pipe elbows are essential fittings used in shipbuilding and maritime systems where strength, corrosion resistance, and lightweight construction are critical.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

View Details

Leave a Message