Customized Marine Aluminum Pipe Elbow for Marine Applications

Marine environments demand robust, corrosion-resistant, and precisely fabricated piping components built to withstand harsh seawater exposure and mechanical stresses. Our Customized Marine Aluminum Pipe Elbows are engineered specifically for marine applications, offering outstanding durability, lightweight properties, and exceptional resistance to saltwater corrosion. Leveraging advanced aluminum alloys and strict quality control standards, these elbows provide reliable bending solutions for fluid transport systems aboard ships, offshore platforms, and dockside facilities.

Material Specification

Our pipe elbows are sourced from premium marine-grade aluminum alloys, primarily from the 5xxx series, predominantly Aluminum 5083 and 5456 alloys, celebrated for their balance between corrosion resistance, tensile strength, and workability.

| Parameter | Value | Standard Specifications |

|---|---|---|

| Alloy | 5083, 5456 (Customized alloys possible) | ASTM B209, ISO 209-2 |

| Temper | H321 (strain hardened and stabilized) | ASTM B209 / MIL-HDBK-5H |

| Density | 2.66 g/cm³ | ASTM B115 |

| Tensile Strength | 290 - 350 MPa | ASTM B954 / ASME B31.3 |

| Yield Strength | 145 - 215 MPa | ASTM B209 |

| Elongation at Break | ≥ 10% | MIL-HDBK-5H |

| Corrosion Resistance | Excellent in seawater | ASTM G85, ASTM B117 (Salt Fog) |

| Surface Finish | Smooth/Polished, Option: painted or anodized | Per project requirements |

Product Dimensions and Types

- Elbow Angle: 45°, 90°, 180°

- Diameter Range: 25 mm up to 600 mm OD

- Wall Thickness: According to ASME B36.10M or customer requirements

- Radius: Standard LR (Long Radius), SR (Short Radius), Customized radii

Manufacturing & Standards Compliance

Our manufacturing process adheres to stringent international standards to guarantee dimensional accuracy, structural integrity, and long-term reliability:

- Fabrication Techniques: Hot forming and cold bending processes under controlled thermal conditions to maintain temper characteristics (principally H321 temper).

- Welding: Typically assembly with high-quality TIG welding using compatible marine-grade filler wires (e.g., AA5.10 ER5356) per AWS D17.2 standard.

- Testing & Inspection: Each elbow undergoes:

- Dimensional verification according to ASME B16.9

- Non-destructive testing (NDT) such as dye penetrant inspection (DPI) or ultrasonic testing (UT) for weld defects

- Corrosion resistance checks per ASTM B117 salt spray testing

- Pressure testing compliant with marine engineering guidelines (ISO 17459)

Application Scenarios

- Marine Piping Systems: Incorporation into seawater cooling systems, ballast piping, HVAC, bilge lines, and fuel transport networks.

- Offshore Platforms: For handling corrosive sub-sea arrangements and piping connecting manifolds and risers.

- Boat Manufacturing: Utilized in exhaust, ventilation, and hydraulic circuits requiring lightweight but strong pipe fits.

- Harbor and Shipyard Installations: Customized elbows installed in fixed pipelines exposed frequently to seawater and salty atmosphere.

Advantages for Marine Environments

- Superior Saltwater Corrosion Resistance: The alloy's naturally forming aluminum oxide film substantially reduces oxidation and surface degradation in marine atmosphere.

- Lightweight with High Strength: Reduces overall structurally induced stress on marine vessels aiding fuel efficiency and installation ease.

- Customization: Adaptations in bend angle, wall-thickness, and surface treatments assure adherence to specific project and vessel designs.

- Eco-Friendly: Aluminum is fully recyclable and offers a sustainable material choice for marine constructors.

Ordering and Customization

Customers can request customization regarding:

- Alloy choice and tempering

- Geometric specifications (angle, radius, diameter)

- Surface treatment (plain, anodized, painted, powder-coated)

- Welding type include flange connections, butt weld ends or threaded ends as per requirement.

- Packaging tailored for overseas marine logistics to mitigate physical and corrosion damages during transit.

Our expert engineering team supports detailed drawings review, finite element analysis (FEA) simulations on mechanical loads, and lifetime corrosion forecasts for critical piping systems.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

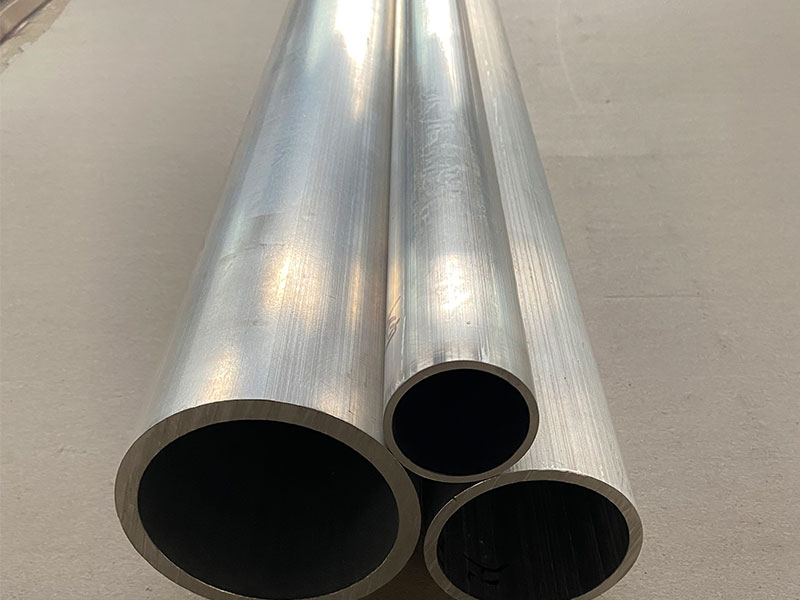

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

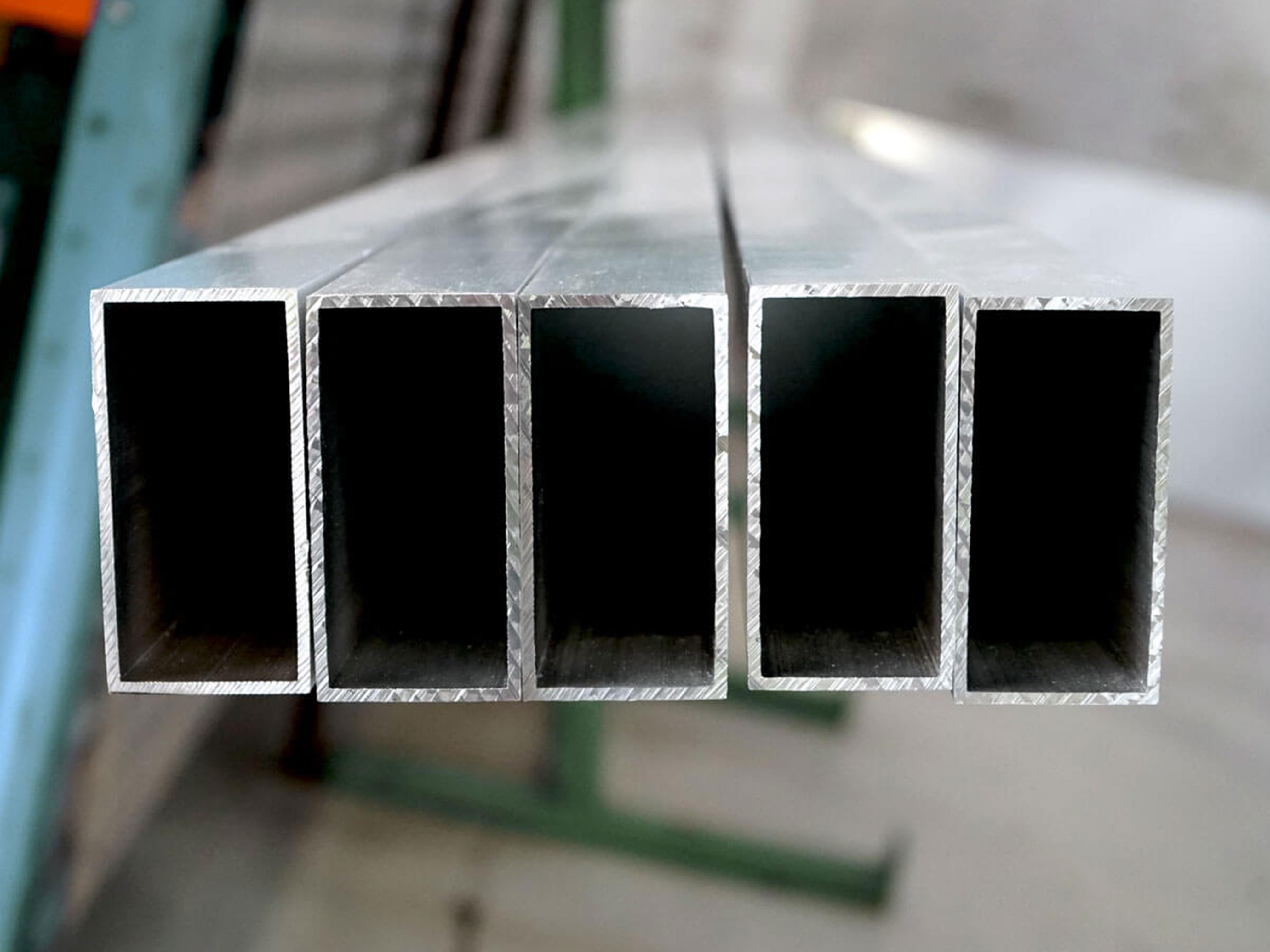

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

Custom Marine Aluminum Elbow for Ship to Ship Fuel Transfer

In the intricate and highly demanding marine environment, efficient and reliable fuel transfer is paramount — especially during ship-to-ship (STS) operations. Central to this process is the often unsung hero: the custom marine aluminum elbow.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details

Leave a Message