6061 Marine Aluminum Tubes for Marine Machinery Support Systems

6061 Marine Aluminum Tubes: Essential for Marine Machinery Support Systems

In the complex machinery and construction of the marine industry, the materials crafted for durability and management play a pivotal role. A standout choice for numerous applications within marine machinery support systems is 6061 marine aluminum tubes. This alloy stands out due to its lightweight formation along with exceptional corrosion resistance, making it the ultimate material for marine environments.

Functions of 6061 Marine Aluminum Tubes

6061 marine aluminum has various functions in support systems aboard vessels. Here are a couple of distinguished ways it enhances marine operations:

Weight Management: Ships and boats rely significantly on weight reduction when it comes to performance. The use of 6061 marine aluminum integration into structural components such as supporting frames and tubing plays a vital role. Its lower weight means increased speed through the water with improved fuel efficiency.

Corrosion Resistance: For equipment immersed in saline environments, the ability to fend off rust and other corrosion factors is non-negotiable. 6061 tubes are alloyed primarily with silicon and magnesium, forming a protective oxide layer against harmful marine elements.

Applications in Marine Machinery Support Systems

From supporting physical structures to intricate machinery implementations, 6061 marine aluminum tubes serve crucial functions which include:

Piping Systems: The tubes are utilized seamlessly within piping systems, acting as conduits for both liquids and gases in challenging marine environments.

Frame and structure fabrication: On the construction site for marine vessels, 6061 tubes provide a sturdy modular capability while lightening the ship’s overall structure. They can create various frameworks ranging from battens, to angled stands and brackets, fulfilling multi-purpose roles.

Hydraulic Shops: Many installations, like hydraulic lifting systems for docking or loading machinery, also employ 6061 tubes given their high strength combined with low weight ratio.

Technical Details & Specifications

When diving deeper into the technical attributes of 6061 marine aluminum tubes, various standards and parameters define their profile. Here is an overview table elucidating these aspects:

| Property | Value |

|---|---|

| Alloy Type | 6061 |

| Chemical Composition | Aluminum Base: ≥ 95.7% |

| Silicon (Si): 0.40-0.80% | |

| Iron (Fe): ≤ 0.70% | |

| Copper (Cu): 0.15-0.40% | |

| Manganese (Mn): ≤ 0.15% | |

| Magnesium (Mg): 0.8-1.2% | |

| Chromium (Cr): 0.04-0.35% | |

| Temper Designation | T6 - Tensile Strength |

| Yield Strength | 276 MPa (40,000 psi) |

| Ultimate Tensile Strength | 310 MPa (45,000 psi) |

| Elongation | 12% |

| Standards Compliance | ASTM B221 & B241 |

| ISO 15305 |

Alloy Temper Designation and Implementation

After primary processing, aluminum alloys take on conditions termed “temper”, which determines specific mechanical attributes. 6061-T6 represents one of the most robust durable forms available, characterized by extensive strains during processing cementing cohesive strength and rigidity.

Conclusive Heating Treatments & Insert Transition Conditions

Further tailoring alloy 6061 coatings to enhance performance attributes during practical applications can make substantial discernable advancements. When necessary, local heating sequences heighten tensile resistance further to exceed critical standards ensuring safety and functionality remain intact 'even under undue pressure'.

Given its multitude of functionalities and extended utility in specialization designs performing under harsh, corrosive marine conditions along with elevated implications associatively directed towards enhanced evocative survival exponentially under strenuous parameters, the implementation of 6061 marine aluminum tubes in machinery support systems increasingly ranks dependent on capacities identified compared to intrinsic limitations of traditional materials.

Their well-rounded chemical properties, lightweight nature, and enhanced strength-to-weight ratio make 6061 essential not only in marine support systems but eye-catching across diverse technological fields requiring high performance under heavy-duty conditions. Marine engineers and shipbuilders will increasingly benefit from integrating this robust alloy appropriate for extending lifetime returns and eco-efficient operational span.

Related Products

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

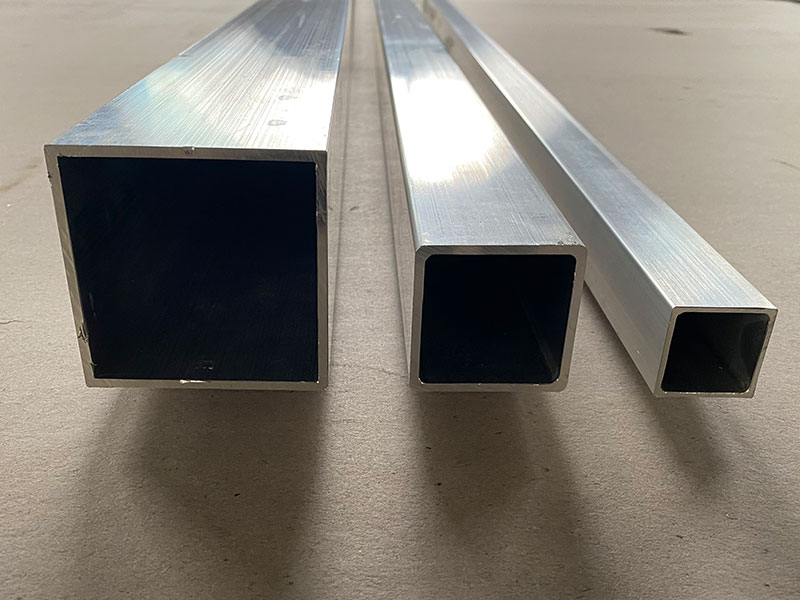

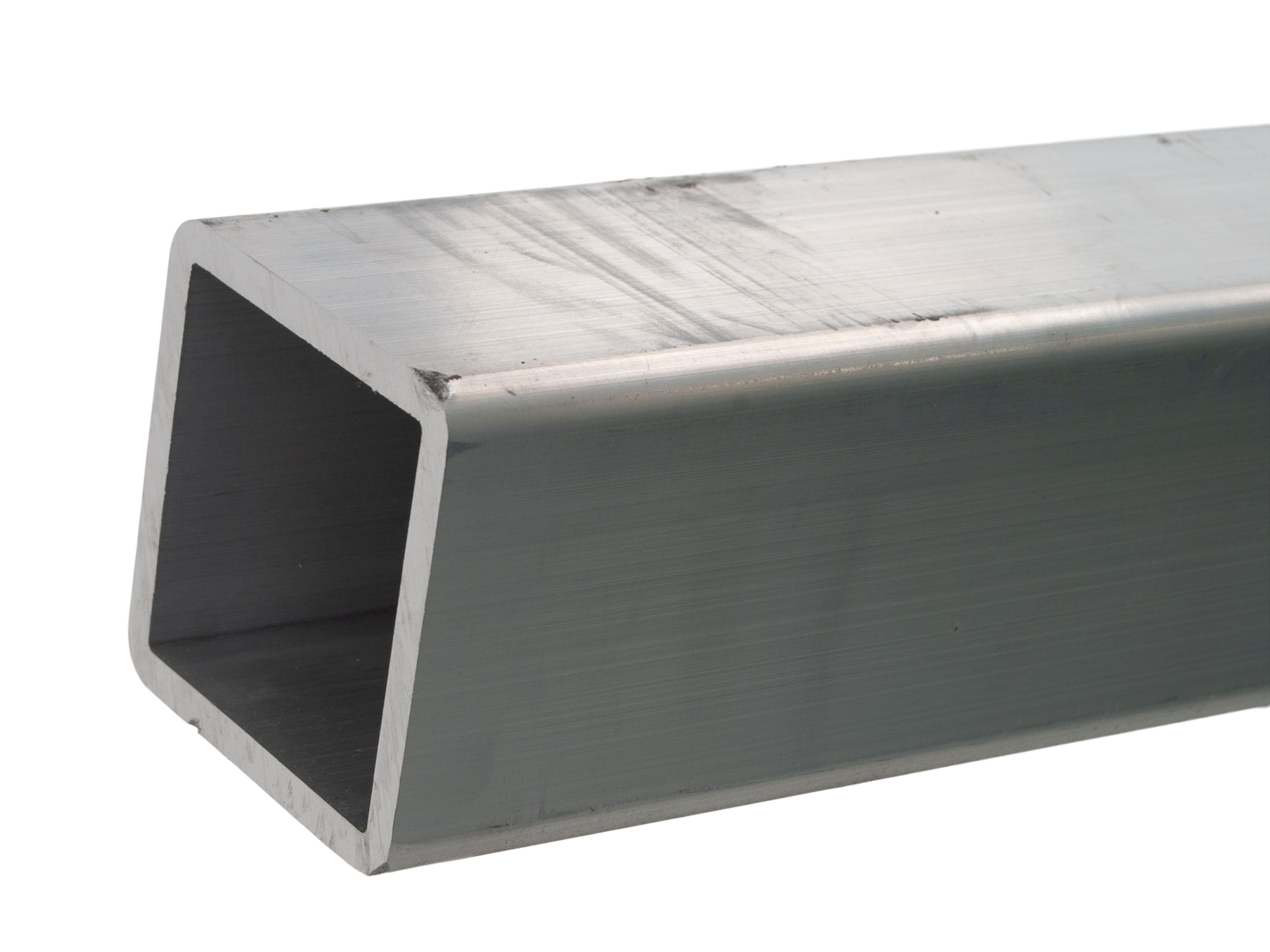

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View Details6061 Marine Aluminum Tubes for Marine Machinery Support Systems

6061 Marine Aluminum Tubes: Essential for Marine Machinery Support SystemsIn the complex machinery and construction of the marine industry, the materials crafted for durability and management play a pivotal role.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals.

View Details6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View Details

Leave a Message