High Quality Marine Aluminum Elbow for Boat Exhausts

High Quality Marine Aluminum Elbow for Boat Exhausts: Functions, Applications and Technical Insight

Marine exhaust systems work in one of the harshest environments on a vessel. Heat, vibration, saltwater spray and corrosive exhaust gases all converge in one compact area. At the heart of this system, the marine aluminum elbow directs and cools exhaust flow while protecting the engine, hull and crew. its materials, design parameters and standards helps you choose components that are reliable, durable and compliant with marine regulations.

Functional Role of a Marine Aluminum Exhaust Elbow

The exhaust elbow is more than a bent pipe. In a properly designed marine exhaust system, it serves several critical functions that interact with each other.

First, it redirects hot exhaust gas from the engine outlet to the main exhaust line, typically turning 45°, 60° or 90° to fit within tight engine compartments and follow the routing to the transom or side discharge. The geometry of the elbow must manage gas velocity and turbulence to avoid excessive backpressure that can reduce engine efficiency.

Second, in many marine installations the elbow is the point where cooling water is injected into the hot exhaust stream. This mixed-flow zone is highly aggressive: hot gas, water, dissolved salts and combustion by-products all meet at the same interface. A marine-grade aluminum elbow must withstand this thermal shock and electrochemical attack while maintaining structural integrity.

Third, the elbow helps separate and guide the gas and water flow to minimize reversion, where water may be forced back towards the engine under certain load or wave conditions. Correct internal contour and wall thickness play a role in reducing this risk.

Finally, its compact, bent shape allows shipyard designers to make better use of confined space, reducing the footprint of the exhaust system and enabling cleaner, more maintainable engine room layouts.

Why Marine Aluminum is an Effective Exhaust Elbow Material

From a metallurgical standpoint, marine aluminum alloys deliver a combination of strength, corrosion resistance and workability that is tuned for seawater and marine atmospheres. The alloys used for exhaust elbows are typically from the 5000 and 6000 series, such as 5083, 5086 or 6061, which are already well established in the marine industry for hulls, decks and structural components.

These alloys provide several advantages in exhaust elbow applications. They have good resistance to seawater corrosion due to their magnesium content and, in some cases, additional manganese or silicon. This is particularly important in the water-injection areas of the elbow. They maintain strength over a wide temperature range and handle high-cycle vibration without cracking when properly designed and welded.

Aluminum is also significantly lighter than stainless steel. In a boat, reduced weight in the engine room directly influences fuel consumption, speed and stability. Lighter exhaust components also lower loads on mounts, brackets and connected piping.

Parameters of a High Quality Marine Aluminum Elbow

When specifying an aluminum elbow for a boat exhaust, several technical parameters define its suitability. These are not just catalogue values; each one translates to performance at sea.

Diameter and wall thickness determine the flow capacity and mechanical strength. Internal diameters are selected according to engine output, exhaust gas volume and acceptable backpressure. The wall thickness must withstand internal pressure pulses and external mechanical loads, while accommodating corrosion allowance over the service life. Typical marine exhaust elbows range from about 50 mm to over 300 mm in diameter, with thickness selected based on class rules and design calculations.

Bend radius and angle control both fit and flow. A tighter radius is useful in constrained spaces but can increase turbulence and pressure loss. Well-designed elbows balance compactness with smooth internal curvature to keep flow losses low. Common configurations include 45°, 60° and 90° elbows, with custom angles available for complex engine room layouts.

Connection type is another critical parameter. Flanged ends, hose nipples or hybrid connections must be compatible with the rest of the exhaust system and meet the pressure rating and vibration conditions. Precision machining of flanges and sealing faces ensures leak-free installation.

Surface treatment and finishing influence corrosion resistance and durability. Processes such as marine-grade anodizing, epoxy coatings or high-build paint systems may be applied, especially on the exterior surfaces exposed to bilge moisture and salt spray.

Alloy Tempering and Its Impact on Performance

Within a given alloy, tempering conditions strongly affect how an elbow behaves in service. Forging, forming and heat treatment adjust the microstructure and mechanical properties.

For 5000 series alloys like 5083 and 5086, typical tempers include O (annealed) and H116 or H321 for marine service. These tempers provide good strength and excellent resistance to stress corrosion cracking while remaining weldable. They are favored where the elbow must endure cyclic loads and a corrosive service environment.

For 6000 series alloys such as 6061, heat-treated tempers like T6 or T651 provide high strength and stability. However, welding in these tempers can locally reduce strength, so post-weld heat treatment or design allowances are considered. In exhaust elbows, 6061-T6 may be used in machined flanges or sections that are subjected to higher mechanical loads but not as heavily welded as the main body.

Choosing the right alloy and temper is therefore a balance between formability, weldability, strength, and resistance to marine corrosion and thermal cycling.

Implementation Standards and Marine Compliance

Marine exhaust elbows must comply with both general material standards and specific marine regulations. High quality products are typically manufactured to recognized standards and, when required, approved by classification societies.

Common material standards include ASTM B209 and B241 for aluminum plate and seamless pipe, EN and ISO standards for aluminum alloys and marine use, and AWS D1.2 or equivalent for aluminum welding procedures.

In marine classification, rules from DNV, ABS, Lloyd’s Register, Bureau Veritas and others define requirements for exhaust system components regarding design pressure, testing, welding qualifications, non-destructive examination and corrosion allowance. For commercial and larger vessels, certification of the elbow and material traceability are often mandatory.

In practice, this means each elbow should be produced with documented mill certificates for base materials, qualified welding procedures and, when specified, hydrostatic or pneumatic pressure testing. For engine rooms with SOLAS requirements, fire protection and insulation arrangements around the elbow may also need to meet specific standards.

Typical Chemical Composition of Marine Aluminum Alloys

Below is an indicative chemical composition table for several common marine aluminum alloys used for exhaust elbows. Values are approximate ranges in weight percent.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40–1.00 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | ≤0.15 | Balance |

| 5086 | ≤0.40 | ≤0.50 | ≤0.10 | 0.20–0.70 | 3.5–4.5 | ≤0.25 | ≤0.25 | ≤0.15 | ≤0.15 | Balance |

| 6061 | 0.40–0.80 | ≤0.70 | 0.15–0.40 | 0.15 | 0.80–1.20 | 0.04–0.35 | ≤0.25 | ≤0.15 | ≤0.15 | Balance |

From a corrosion standpoint, the magnesium content in 5083 and 5086 contributes to their excellent performance in seawater, while controlled copper levels help avoid galvanic sensitivity. 6061, with its silicon and magnesium combination, is valued for strength and machinability, particularly for precision components in the exhaust system.

Applications and Integration on Different Types of Boats

High quality marine aluminum elbows are used across a wide range of vessels, but the engineering focus can vary.

On small pleasure craft and sport boats, weight and compactness are critical. Aluminum elbows allow tighter engine installations while keeping total boat weight down. Their corrosion resistance reduces owner maintenance and extends service life between overhauls.

On commercial workboats, patrol boats and fishing vessels, durability and ease of repair are priorities. Weldable marine aluminum alloys allow field repairs and modifications. Matching elbow materials with aluminum hull structures minimizes galvanic corrosion and simplifies bonding and grounding strategies.

On larger yachts and passenger vessels, noise and vibration control become important. Elbows are integrated with water-injected silencers and flexible couplings, so their geometry and material stiffness are selected to reduce resonance and structure-borne noise without compromising strength.

A Distinctive Technical Perspective: The Elbow as a Controlled Interface

Viewed from a systems engineering perspective, the marine aluminum exhaust elbow is a highly controlled interface between different physical domains. It connects hot gas flow to cooling water flow, metallic structure to flexible hose, engine dynamics to hull structure and high vibration sources to relatively quiet compartments.

Choosing the right alloy, temper and parameters is essentially about managing these interfaces. Corrosion resistance manages the chemical interface between metal and seawater. Wall thickness and bend radius manage the mechanical and fluid dynamic interface between engine pulses and exhaust backpressure. Temper and welding quality manage the fatigue interface between vibration and long-term structural integrity.

By treating the elbow not as an isolated component but as a tuned interface, designers and owners can better appreciate why marine-grade aluminum alloys, appropriate tempers, certified standards and carefully specified parameters are all necessary for a truly high quality marine aluminum exhaust elbow.

For anyone upgrading an exhaust system or specifying components in a new build, paying attention to these technical aspects ensures safer operation, longer service life and lower total cost over the vessel’s lifetime.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

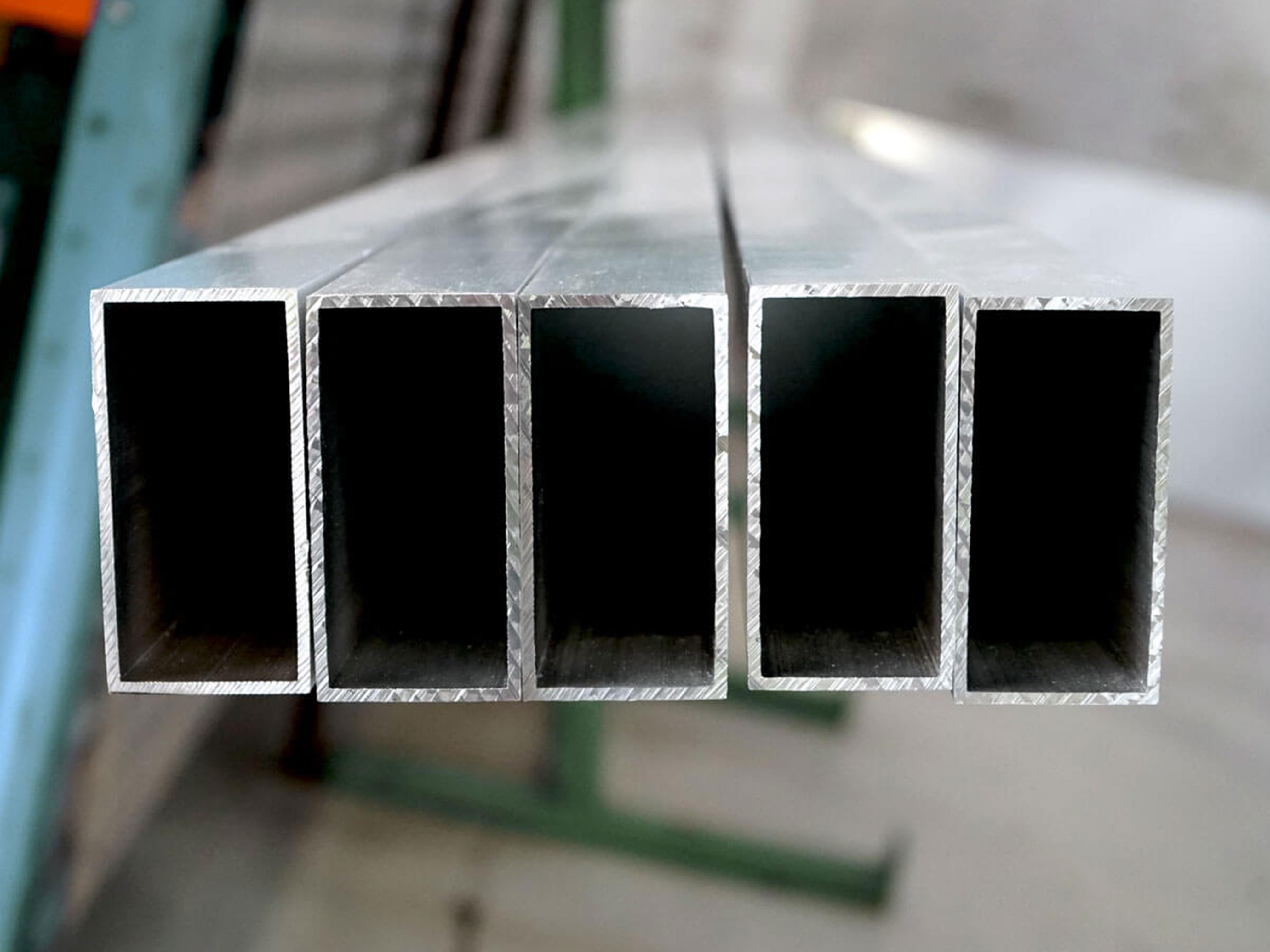

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

Marine Aluminum Pipe Elbow for Desalination Plant Connections

In modern desalination plants, the choice of piping components is critical to ensuring efficiency, longevity, and resistance to harsh marine environments.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View DetailsAluminum Pipe Elbow for Saltwater Marine Piping

Aluminum pipe elbows are essential fittings in saltwater marine piping systems. Designed to change the direction of flow, they combine lightweight construction, corrosion resistance.

View Details6082 Marine Aluminum Tubes for Marine and Offshore Installations

In the ever-evolving domain of marine and offshore engineering, the choice of materials plays a pivotal role in expressing durability, strength, and versatility.

View DetailsAluminum Elbow for Marine Exhaust Systems

In marine engineering, ensuring durability, corrosion resistance, and optimal flow dynamics of exhaust components is crucial for the longevity and performance of onboard systems.

View DetailsMarine Aluminum Elbow for Offshore Oil Spill Containment Systems

Marine Aluminum Elbow for Offshore Oil Spill Containment Systems: Functions, Applications, and Technical InsightsIn the demanding and often harsh environment of offshore oil spill containment systems, every component requires superior performance.

View Details

Leave a Message