Marine Grade Aluminum Pipe Elbow for Ship Engines

Marine-grade aluminum pipe elbows are critical components in modern ship engine systems, connecting straight pipes while allowing directional changes in cooling water, exhaust gas, fuel, and compressed air lines. Designed to withstand harsh marine environments, these elbows combine high corrosion resistance with low weight and excellent mechanical performance, helping shipbuilders and engine OEMs improve efficiency and reliability.

Features at a Glance

| Feature | Benefit in Marine Engine Systems |

|---|---|

| Marine-grade aluminum alloys | Excellent corrosion resistance in seawater and marine atmospheres |

| Lightweight construction | Reduced system weight, improved fuel efficiency, easier handling |

| High thermal conductivity | Efficient heat transfer in cooling and exhaust systems |

| Good weldability | Reliable on-board fabrication, repair, and modification |

| Stable mechanical strength | Maintains integrity under pressure, vibration, and cyclic loading |

| Smooth internal surface | Lower flow resistance, reduced fouling, improved system efficiency |

| Multiple bend radii and angles | Flexible layouts in tight engine rooms and complex routing paths |

| Compliance with marine standards | Easier design approval and class certification |

Typical Aluminum Alloys Used

Marine-grade pipe elbows are commonly manufactured from 5xxx and 6xxx series aluminum alloys. Actual grade selection depends on the medium (seawater, fuel, air, exhaust), temperature, and required strength.

Common Marine Aluminum Alloy Grades for Pipe Elbows

| Alloy Grade | Temper | Typical Use in Ship Engine Systems |

|---|---|---|

| 5083 | O / H111 | Seawater cooling lines, ballast, general ship piping |

| 5086 | O / H32 | High-corrosion-resistance cooling and service water lines |

| 6061 | T6 / T651 | Compressed air, fuel, hydraulic return, structural supports |

| 6082 | T6 | High-strength applications near engines and machinery |

Representative Chemical Composition

The exact composition depends on the alloy and producer; the following tables give typical ranges as per common marine grades used in pipe elbows.

Alloy 5083 (Typical Composition, wt%)

| Element | Min (%) | Max (%) |

|---|---|---|

| Mg | 4.0 | 4.9 |

| Mn | 0.4 | 1.0 |

| Cr | 0.05 | 0.25 |

| Si | – | 0.40 |

| Fe | – | 0.40 |

| Cu | – | 0.10 |

| Zn | – | 0.25 |

| Ti | – | 0.15 |

| Others | – | 0.15 |

| Al | Balance | Balance |

Alloy 6061 (Typical Composition, wt%)

| Element | Min (%) | Max (%) |

|---|---|---|

| Mg | 0.8 | 1.2 |

| Si | 0.4 | 0.8 |

| Cu | 0.15 | 0.40 |

| Cr | 0.04 | 0.35 |

| Fe | – | 0.70 |

| Zn | – | 0.25 |

| Ti | – | 0.15 |

| Others | – | 0.15 |

| Al | Balance | Balance |

Mechanical and Technical Specifications

Mechanical properties vary with alloy and temper. The table below summarizes common property ranges at room temperature for typical marine elbows.

Representative Mechanical Properties

| Property | 5083-O / H111 | 6061-T6 |

|---|---|---|

| Tensile Strength Rm (MPa) | 270 – 340 | 260 – 310 |

| Yield Strength Rp0.2 (MPa) | 120 – 215 | 240 – 280 |

| Elongation A50 (%) | 10 – 20 | 8 – 12 |

| Brinell Hardness HB | 75 – 95 | 85 – 100 |

| Density (g/cm³) | ~2.66 | ~2.70 |

| Modulus of Elasticity (GPa) | ~70 | ~69 |

| Thermal Conductivity (W/m·K) | 120 – 130 | 150 – 170 |

| Coefficient of Expansion (10⁻⁶/K) | 23 – 25 | 23 – 24 |

Dimensional Range for Marine Pipe Elbows

Actual sizes differ by standard and project, but typical ranges are as follows:

| Parameter | Typical Range |

|---|---|

| Nominal Diameter DN (mm) | 15 – 600 |

| Outside Diameter (mm) | 21.3 – 610 |

| Wall Thickness (mm) | 2.0 – 25.0 |

| Standard Bend Angles | 45°, 90°, 135°, custom angles on request |

| Bend Radius | Short radius (R ≈ 1D), long radius (R ≈ 1.5D–2D) |

| End Type | Plain end, beveled end, flanged, or custom |

| Surface Finish | Mill finish, brushed, anodized, coated |

Corrosion Resistance in Marine Environments

Marine-grade aluminum pipe elbows offer excellent resistance to:

- Seawater and brackish water

- Salt spray and marine atmosphere

- Many coolants and non-aggressive fuels

For long service life in ship engines, corrosion performance is especially important in seawater cooling circuits and piping running near the waterline.

Corrosion-Related Properties

| Parameter / Behavior | Marine-Grade Aluminum Elbows |

|---|---|

| Seawater resistance | Very good, especially 5xxx alloys |

| Stress corrosion cracking | Low susceptibility in 5xxx below ~70 °C |

| Pitting and crevice corrosion | Moderate; mitigated by proper design and alloy selection |

| Galvanic corrosion with steel/brass | Possible; requires insulation and proper joints |

| Protective surface options | Anodizing, epoxy painting, powder coating |

Compatibility with Ship Engine Systems

Aluminum elbows are often preferred in systems that benefit from reduced weight and good thermal conductivity while operating within aluminum’s temperature limits.

Typical Media and Operating Limits

| Medium / Line Type | Typical Use of Aluminum Elbows | Recommended Temperature Range* |

|---|---|---|

| Seawater cooling lines | Widely used due to corrosion resistance and low weight | Up to ~70–80 °C |

| Freshwater / glycol coolant | Common, particularly in auxiliary circuits | Up to ~80–90 °C |

| Lube oil return lines | Selective use in low-pressure, moderate temperature areas | Up to ~120 °C (depending on alloy) |

| Fuel transfer / return | Used where code and classification allow | Follow fuel and class rules |

| Compressed air lines | Frequent use due to light weight and clean internal bore | Up to ~120 °C |

| Exhaust gas systems | Limited, mostly low-temperature sections | Below ~150 °C |

* Always follow alloy datasheets, class rules, and project specifications.

Manufacturing and Joining

Marine grade aluminum pipe elbows are typically produced by:

- Hot forming or cold bending seamless pipe

- Extrusion followed by bending

- Mandrel bending with controlled radii

Weldability is a advantage. Elbows can be welded to aluminum pipes and fittings directly on board.

Welding and Fabrication Data

| Aspect | Typical Recommendation |

|---|---|

| Common welding processes | GTAW (TIG), GMAW (MIG) |

| Typical filler wires | ER5183, ER5356 (for 5xxx alloys), ER4043 (for 6xxx) |

| Preheating | Normally not required; moderate preheat in thick sections |

| Post-weld heat treatment | Usually not applied on 5xxx; controlled for 6xxx |

| Machinability | Good for 6xxx, fair for 5xxx |

Main Applications in Ship Engines

Marine grade aluminum pipe elbows are well-suited for a variety of systems in engine rooms and machinery spaces.

Typical Application Areas

| System / Zone | Function of Aluminum Pipe Elbows |

|---|---|

| Main engine jacket water cooling | Directs coolant through tight spaces and around engine blocks |

| Auxiliary engine cooling | Routes cooling water in compact generator sets and auxiliaries |

| Central cooling and chiller systems | Connects coolers, pumps, and manifolds with minimal pressure loss |

| Ballast and service water lines | Lightweight routing above the waterline |

| Compressed air systems | Connects compressors, receivers, and distribution headers |

| Fire-fighting support lines* | Non-critical auxiliary lines where permitted by rules |

| HVAC and ventilation duct piping | Light structural and fluid transport elbows |

* Use in safety-critical lines must follow flag state, IMO, and classification requirements.

Advantages Over Steel in Marine Engine Rooms

When compared with carbon or stainless steel elbows, aluminum elbows offer several system-level advantages.

| Criterion | Marine Aluminum Elbows | Carbon Steel Elbows |

|---|---|---|

| Density | ~2.7 g/cm³ (about one-third of steel) | ~7.8 g/cm³ |

| Corrosion resistance | Very good in marine atmosphere | Requires coatings and maintenance |

| Weight of piping system | Significantly lower | Higher |

| Installation effort | Easier handling and lifting | Heavier handling, more support needed |

| Magnetism | Non-magnetic | Magnetic |

| Life-cycle cost | Reduced maintenance, lower lifetime cost | More maintenance, heavier structures |

This weight reduction is particularly valuable in high-speed craft, fast ferries, patrol boats, and offshore support vessels, where every kilogram matters.

Quality, Standards, and Certification

To ensure safe operation in ship engines, marine grade aluminum pipe elbows are typically supplied in accordance with international standards and classification requirements.

Typical Standards and Certification Options

| Category | Examples (Project Dependent) |

|---|---|

| Material standards | EN 573, EN 485, EN 754, ASTM B241 / B361 |

| Dimension norms | EN 10253-type dimensions (adapted to aluminum), custom shipyard specs |

| Testing | Dimensional check, visual inspection, pressure test on request |

| Class approval | DNV, ABS, LR, BV, RINA, CCS depending on project |

| Documentation | Mill test certificate (EN 10204 3.1/3.2), welding procedure records, coating reports |

Choosing the Right Marine Grade Aluminum Pipe Elbow

When selecting elbows for ship engines, the following design parameters should be confirmed:

| Design Parameter | What Should Be Defined |

|---|---|

| Medium and temperature | Type of fluid/gas, operating and peak temperatures |

| Pressure rating | Design pressure, test pressure, safety factors |

| Alloy and temper | Based on corrosion, strength, and weldability requirements |

| Size and thickness | Nominal diameter, wall thickness, bend radius |

| End connection | Welded, flanged, threaded adapter, or mixed configurations |

| Surface protection | Bare, anodized, painted, or coated for specific environments |

| Classification requirements | Applicable rules, flag state, and class notation |

By clearly defining these parameters, shipyards and engine integrators can specify elbows that deliver long service life, reduced maintenance, and optimal flow performance in demanding marine conditions.

Marine grade aluminum pipe elbows for ship engines combine corrosion resistance, low weight, and reliable mechanical performance, making them a strong choice for modern marine piping systems, particularly in cooling and auxiliary lines where weight and efficiency are critical.

Related Products

Custom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

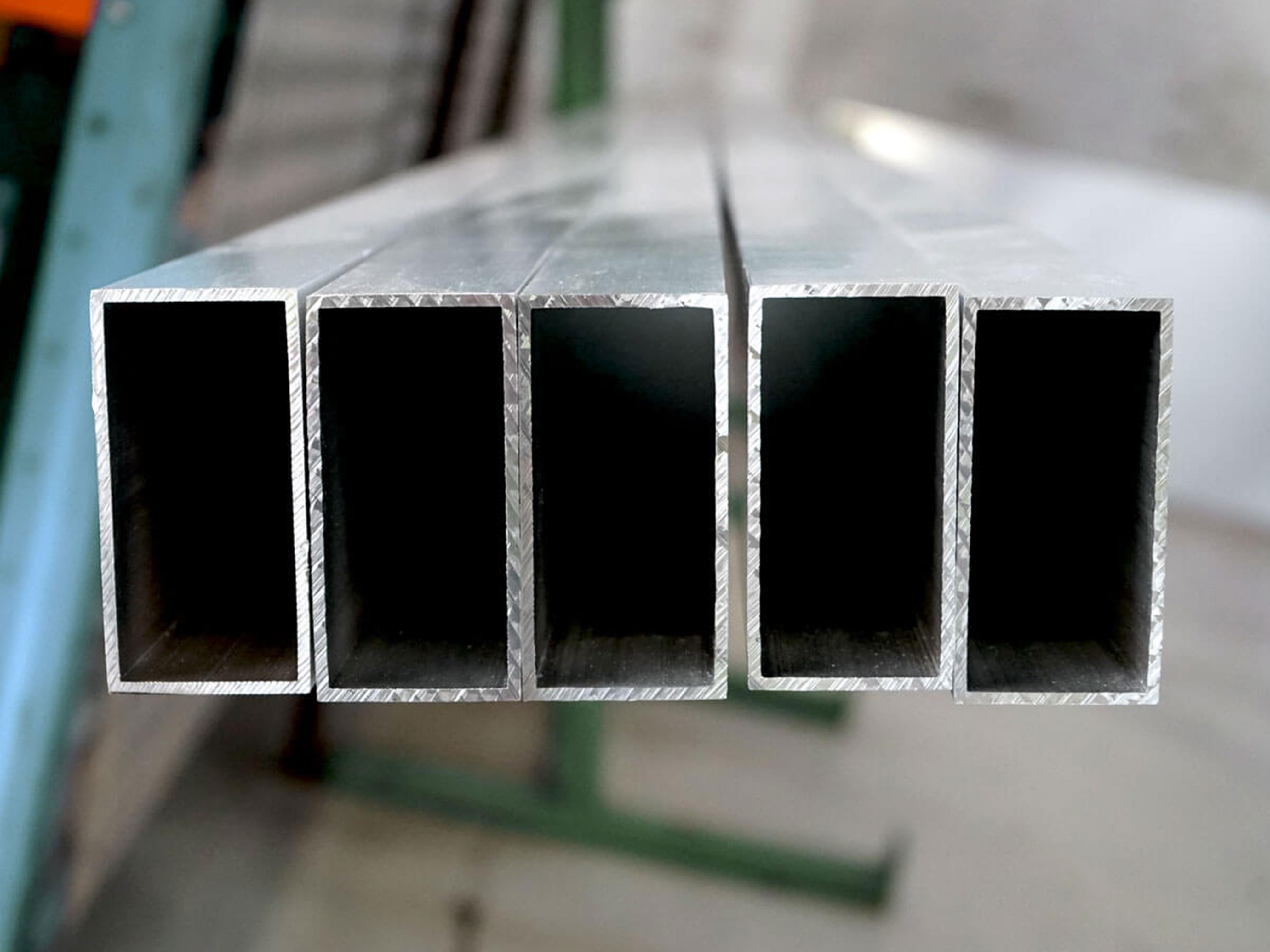

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View DetailsMarine Aluminum Elbow for Combustion Air Supply Systems

In the demanding environment of marine vessels, reliable components contribute immensely to safety, efficiency, and longevity. Among such vital parts.

View DetailsMarine Aluminum Elbow for Saltwater Intake and Pumping Systems

Our Marine Aluminum Elbow designed specifically for saltwater intake and pumping systems—engineered for maximum corrosion resistance, durability, and strength in harsh marine environments.

View Details5083 Marine Aluminum Tubes for Coastal Boat Building

Marine Aluminum is a prominent material in the marine industry due to its exceptional properties, which makes it the perfect choice for constructing strong, lightweight vessels.

View DetailsDurable Marine Aluminum Pipe Elbow for Saltwater Environments

In the world of marine engineering, strength, corrosion resistance, and lightweight characteristics play a pivotal role. As the demand for more resilient and efficient installations surges.

View Details6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details

Leave a Message