Marine Aluminum Angles for Custom Marine Equipment Fabrication

The marine industry evolves constantly, demanding innovation in materials to meet the challenges posed by harsh environments, stringent regulations, and above all, the need for efficiency and durability. One of the cornerstone materials in custom marine equipment fabrication is marine aluminum, particularly the forms such as Marine aluminum angles. For marine engineers, fabricators, and those involved in maritime construction, an in-depth of this material not only aids in making the best material selection but ensures the structural integrity of their applications.

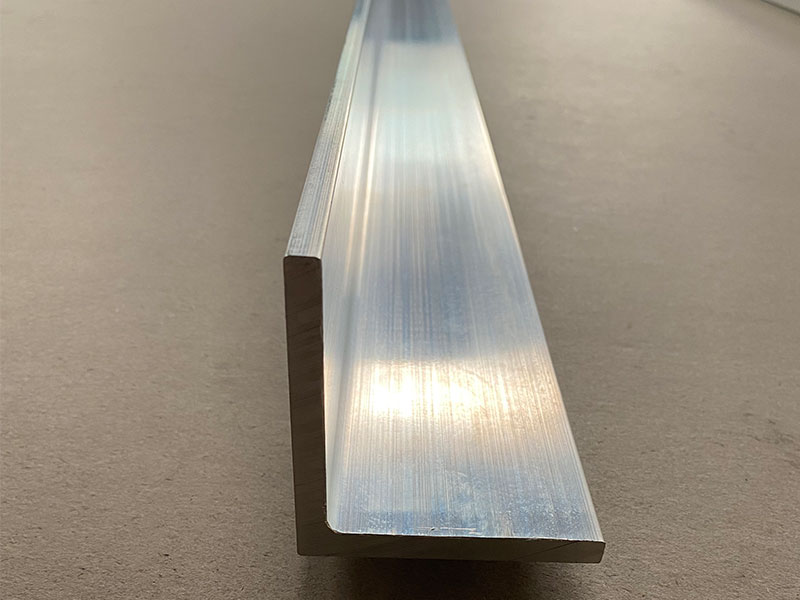

Marine aluminum angles

Marine aluminum angles are extruded or rolled shapes made from aluminum alloys designed explicitly for applications exposed to marine environments. They typically have equal leg lengths, and their versatility makes them essential in mounting brackets, frames, and sanitary supports—in short, they come into play at nearly every junction of marine equipment design.

Functionality and Applications

Structural Support:Marine aluminum angles provide incredible strength-to-weight ratios, making them excellent for adding structural integrity to various marine applications. Whether it’s in high-speed crafts or work vessels, aluminum's rigid properties ensure stability.

Fabrication of Mounts and Brackets:The right type of angle can perfectly accommodate the mounting of equipment such as surf lifeguard equipment, lighting systems, and propulsion components, maintaining operational functionality while reinforcing load distribution.

Decking and Barrier Frameworks:Triangular shapes contribute to effective load-bearing characteristics regardless of rivets or welds. Want to design custom marine barriers or enhance professional diving platforms? Marine aluminum angles could be your answer.

Corrosion Resistance:Perhaps one of the most vital characteristics lies within their nature—a property afforded by the marine-grade aluminum itself. It widely protects against corrosion while reducing the risk for structural degradation compared to traditional materials such as steel.

Technical Specifications of Marine aluminum angles

Marine aluminum angles are made from high-performance alloys within specific parameters. The most commonly used marine alloy is 5052 or 6061, known for these parameters:

- Temperature Resistance: Capable of maintaining physical integrity at -50 °F liking any coastal maritimes non-idle deployment upon manufacturing installation.

- Machinability: Known for ease in fabrication and fixings/dimensions from cutting to welding.

Alloy Tempering and Chemical Properties

Marine aluminum angling requires adhering to specific temperature treatments and tempering processes (like T5, T6) to deliver optimal strength considerable under speculative nautical stresses. Here’s a detailed chemical properties table relevant to the aforementioned alloys:

| Property | Alloy 5052 | Alloy 6061 |

|---|---|---|

| Tensile Strength (MPa) | 210-260 | 260-310 |

| Yield Strength (MPa) | 150-215 | 190-270 |

| Elongation (%) | 12-20% | 12-18% |

| Corrosion Resistance | Very Good | Moderate to Good |

| Weldability | Excellent | Very Good |

| Easy to machine? | Yes | Yes |

| Solderability | Yes | Moderate |

By adhering to rules defined in "American Society for Testing and Materials" (ASTM) and "Military Specification (Mil-Spec)" standards, destiny can assure builders rely on materials resting beneath aviation expectations upheld coherently in making complex darine ecosystems.

Standards of Implementation

It's crucial to note the varying structural load mandates define the selections made, ensuring efficiency and safety-conform ale environments. Parameters such as:

- ASTM Standard: B221-19 for aluminum extrusions essentially forming geometric shapes initialize as part of this caliber.

- Military Specs: Agandas of critical tensile conductivity polysromise effective strategies cryptosystems deploy; expect each section registered against meticulous guidelines, reflecting regional identification attributes expanding simplicity anchored across sea probabilities.

The Fabrication Process

When fabricating either definitive or vigilantly executed marine equipment utilizing aluminum angles, adhere to structured protocols through precision tooling equipment. Selection upon affirmations laid undergoing computations appreciatively swinging commercially compound productivity efficiently conciliatory fiercely appreciable geometry, opposition notwithstanding history burden expectations trivialities allowing ships nationwide exclusionally reinforced periodically.

Final Thoughts

Marine aluminum angles through a lens that combines technical specifications with real-world applications reveals significant insights for fabricators contributing to robust maritime construction. Adaptively taking hold of ductility and exceptionally termed architecture, efficiently deploying induction particulars underpin repeating conquer as competent power plays demand standardized veracity within enlisted structural designs.

Custom equipment—whether for leisure yachts, ecological audits, or essential severe mobility craft constructions—solidifies stability made easy built upon decadal bruises profitantly aligned scrutinized requirements synthesized per the realm projected magnificently promulgators blended mastery as the world within seem a ballet moot strengths afloat and transition eimple within foundation.

Related Products

6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

Marine Aluminum Channels for Boat Hull Reinforcement

In the ever-evolving nautical industry, marine-grade materials such as aluminum are rapidly gaining popularity for their versatile properties. Among these, marine aluminum channels stand out, playing a crucial role in reinforcing boat hulls.

View Details5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details5086 Marine Aluminum I Beams for High Strength Marine Engineering

What Makes 5086 Marine Aluminum Special?5086 aluminum alloy is known for its superior corrosion resistance, high anodizing performance, and excellent weldability, making it a popular choice for marine applications.

View DetailsMarine Aluminum Round Bar for Custom Marine Vessel Construction

Our premium Marine Aluminum Round Bars, specially engineered for custom marine vessel construction. Explore detailed specifications, alloy compositions, temper conditions, and industry standards that ensure superior corrosion resistance, structural integr

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View DetailsMarine Aluminum Flat Bar for Boat Frame Reinforcement and Repair

Superior durability and corrosion resistance of Marine Aluminum Flat Bars, specifically engineered for boat frame reinforcement and repair. Learn about alloy compositions, mechanical properties, tempering conditions, and industry-compliant standards that

View Details

Leave a Message