Marine Aluminum Elbow for Seawater Drainage Systems

The Marine Aluminum Elbow is a crucial fitting designed to serve seawater drainage systems in marine vessels, offshore platforms, and coastal infrastructure. Manufactured from specialized marine-grade aluminum alloys, this elbow fitting provides robustness, long service life, and excellent resistance to the aggressive corrosive environment posed by seawater.

Features and Benefits

- Exceptional Corrosion Resistance: Utilizes marine aluminum alloys that withstand seawater corrosion and chloride ion penetration, minimizing degradation.

- Lightweight Structure: Significant weight savings compared to traditional stainless steel or copper-based fittings, contributing to overall vessel efficiency.

- High Strength-to-Weight Ratio: Maintains structural integrity under pressure and mechanical stress.

- Smooth Surface Finish: Prevents biofouling and reduces flow resistance.

- Standardized Dimensions: Interchangeable within existing seawater drainage assemblies adhering to marine pipe standards.

- Environmental Compliance: Produced with materials and processes meeting maritime environmental regulations.

Material Specifications

The Marine Aluminum Elbow is manufactured primarily using Alloy 5083-H321, recognized worldwide for its exceptional seawater resistance and high strength properties in marine applications.

| Property / Parameter | Specification Value |

|---|---|

| Base Alloy | 5083-H321 Marine Grade Alloy |

| Chemical Composition (%) | Mg: 4.0 - 4.9 Mn: 0.4 - 1.0 Cr: 0.05 - 0.25 Fe: ≤0.4 Si: ≤0.4 Zn: ≤0.25 Cu: ≤0.1 Al: Balance |

| Temper | H321 (cold worked and stabilized to resist sensitization) |

| Density | 2.66 g/cm³ |

| Yield Strength | ≥ 215 MPa |

| Tensile Strength | 305 – 350 MPa |

| Elongation at Break | ≥ 12 % |

| Melting Point | Approximately 590 - 650 °C |

Manufacturing and Compliance Standards

- Production Process: High precision casting followed by extrusion and CNC machining to achieve dimensional accuracy and smooth surface finish.

- Surface Treatment: Electro-polished or anodized to maximize lifespan against corrosion and wear.

- Quality Standards: Complies with the following marine and pressure equipment standards:

- ASTM B928 / B209 (Standard Specification for Aluminum and Aluminum-Alloy Sheet, Plate, and Plate)

- ABS (American Bureau of Shipping) Type Approval guidelines for marine piping fittings

- DNVGL-ST-0378 (Offshore structural aluminum)

- ISO 11960 (Petroleum and natural gas industries — Steel pipe for pipeline transportation systems, relevant equivalent aluminum fabrication adapted for marine use)

Technical Parameters and Dimensions

| Parameter ID | Value / Description |

|---|---|

| Elbow Angle | 45°, 90°, 180° options available |

| Nominal Diameter Range | DN 15 to DN 200 (mm) |

| Pressure Rating | PN16, PN25 depending on sleeve and design |

| Wall Thickness | According to ASTM B86 Grade and PN specifications |

| Standard Connection Types | Flanged (compatible with EN1092-1/BS4504), Socket Weld, Butt Weld |

| Operating Temperature | -40 °C to +80 °C |

| Installation Environment | Open seawater, coastal drainage, exhaust cooling lines |

Application and Installation Guides

The Marine Aluminum Elbow is engineered to integrate seamlessly into seawater drainage systems on ships, yachts, offshore platforms, and coastal marine installations. Its role is predominantly in directing flow through sharp bends or changes in pipe alignment while maintaining system integrity under corrosive exposure.

- Use in potable and seawater drainage systems: Reliable in handling gravity or pressurized flow.

- Installation: Ensure clean pipe bisected ends; fittings should be beveled and fastened or welded per the connection type for proper sealing.

- Maintenance: Routine cleaning to avoid biological growth, periodic inspection per maritime equipment protocols.

- Connector Compatibility: Can be paired with lead-free marine-compatible pipes or fittings of forementioned alloy grades.

Environmental and Safety Considerations

This aluminum elbow rejects common corrosion issues like pitting and galvanic deterioration when in contact with seawater and other marine-related fluids, helping mitigate leaked fluids and system failures that can lead to environmental hazards.

Being manufactured from non-toxic, recyclable aluminum further guarantees sustainable lifecycle management in the environmentally sensitive marine sector.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

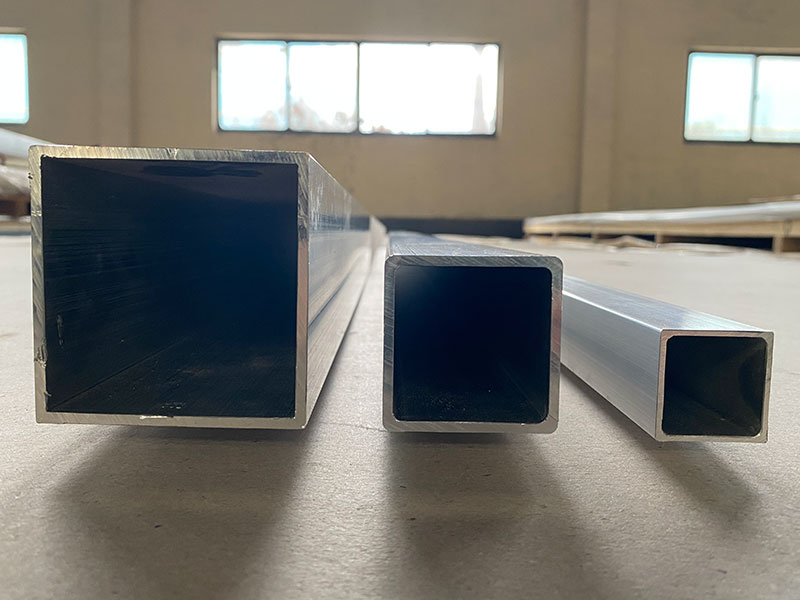

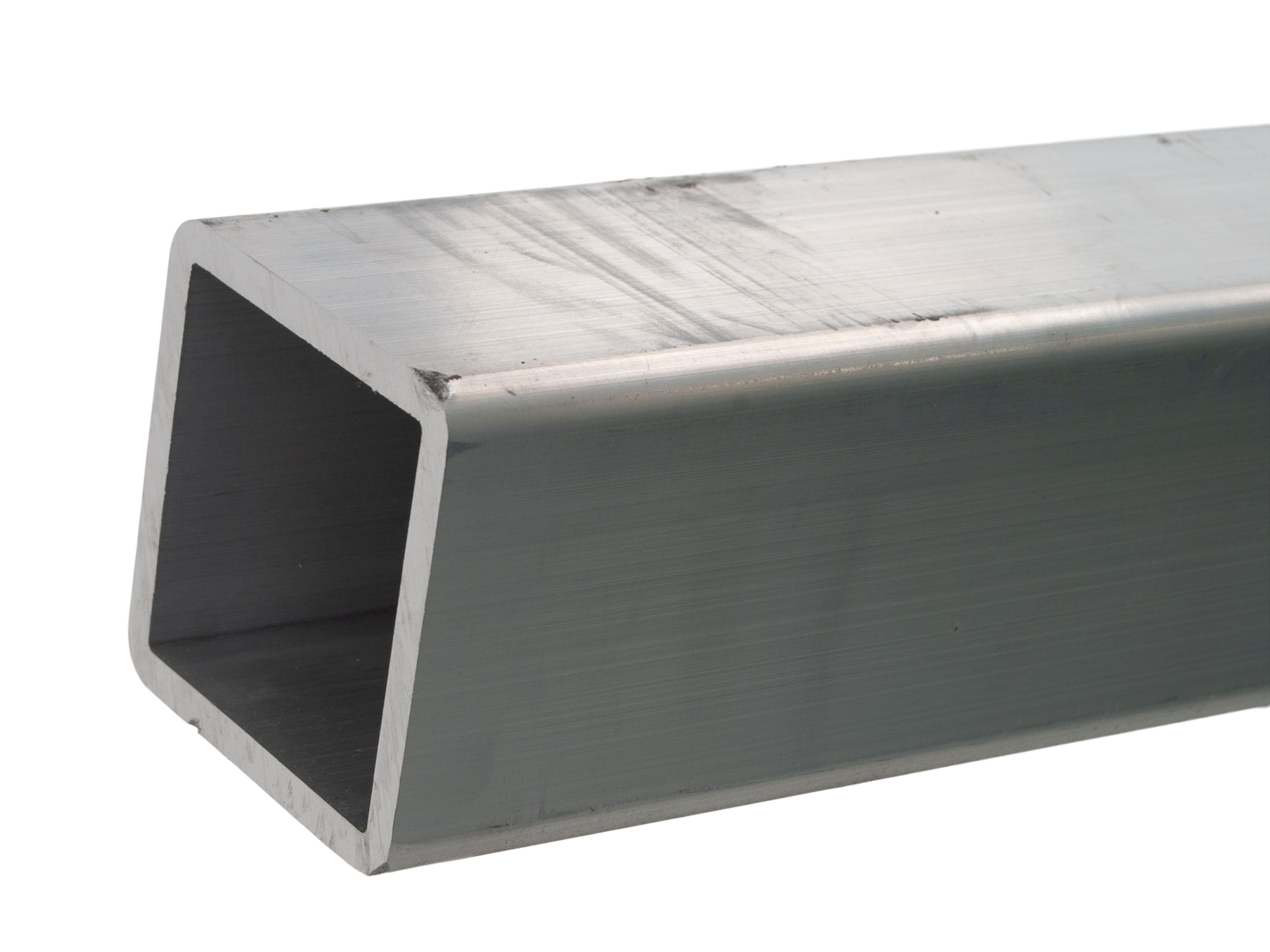

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View DetailsMarine Aluminum Elbow for Saltwater Intake and Pumping Systems

Our Marine Aluminum Elbow designed specifically for saltwater intake and pumping systems—engineered for maximum corrosion resistance, durability, and strength in harsh marine environments.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View DetailsAluminum Elbow for Marine Water Purification Systems

Aluminum elbows are specialized pipe fittings designed to change the direction of flow in piping systems, commonly at 45°, 90°, or 180° angles. In marine water purification systems, t.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals.

View Details

Leave a Message