Marine Aluminum Flat Bar for Heavy Duty Coastal Shipbuilding

Marine aluminum flat bar designed for heavy-duty coastal shipbuilding: high-strength, corrosion-resistant aluminum alloys (commonly 5083, 5086, 6061, 5456) in plate/flat-bar form manufactured to marine grades and tempers. Engineered for hull structure, framing, stringers, decks, fender beams, gangways, and welded superstructure components where saltwater corrosion resistance, high fatigue life, weldability and formability are critical. Available in a wide range of widths, thicknesses and tempers; supplied with mill certificates, NDT options and surface treatments for long-term coastal service.

Features

- High corrosion resistance in seawater and splash zones (especially Al-Mg alloys like 5083/5086/5456).

- Good weldability using common shipyard processes (GMAW, GTAW, SMAW) with reduced pre/post-heat needs for Al-Mg grades.

- High specific strength and fatigue resistance for hull and structural members.

- Excellent formability for bending, roll forming and moderate stamping.

- Lightweight: reduces fuel consumption and increases payload relative to steel.

- Available in common marine tempers (O, H111, H116, H321, T6 for 6xxx series) and customized mechanical-property guarantees.

- Mill testing and documentation: chemical analysis, mechanical testing, UT or PT/MT on request, and traceable certificates (EN 10204 3.1/3.2 or ABS/LR approvals).

- Surface finishes: mill finish, brushed, anodized (for 6xxx series), or protective coatings (conversion coatings, epoxy primers).

- Low magnetic signature and excellent thermal conductivity for certain applications.

Common Applications in Coastal Shipbuilding

- Hull stringers, stiffeners and framing members for coastal vessels and ferries.

- Deck and platform flat bars, fender backing strips, rub rails.

- Transverse and longitudinal stiffeners in hull plating systems.

- Gangways, ladders, walkways and handrail supports.

- Structural members in superstructure and deckhouses where weight saving is critical.

- Fender beams, chocks and bollard backing plates.

- Retrofit and repair components where corrosion resistance is required.

Available Alloys & Typical Choice Guidance

- 5083 / 5086 / 5456 (Al-Mg family): preferred for hull plating, structural members exposed to seawater — excellent corrosion resistance, good strength and weldability.

- 6061-T6 (Al-Mg-Si family): widely used where higher strength and anodizing are required; good for welded structures with heat treatment considerations.

- 5005 / 5052: used for non-structural elements, trim, and formed components — good corrosion resistance and formability.

- 7075 (high strength Al-Zn) rarely used for ship structure due to poor corrosion resistance unless specially treated — used for fasteners and high-strength fittings.

Chemical Composition (typical ranges by alloy)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (balance) |

|---|---|---|---|---|---|---|---|---|---|

| 5083 | 0.4 max | 0.4 max | 0.1 max | 0.4–1.0 | 4.0–4.9 | 0.05–0.25 | 0.25 max | 0.15 max | Remaining |

| 5086 | 0.4 max | 0.4 max | 0.1 max | 0.05–0.5 | 3.5–4.5 | 0.05–0.25 | 0.25 max | 0.15 max | Remaining |

| 5456 | 0.4 max | 0.5 max | 0.1 max | 0.4–1.0 | 4.5–5.6 | 0.05–0.25 | 0.25 max | 0.15 max | Remaining |

| 6061 | 0.4–0.8 | 0.7 max | 0.15–0.40 | 0.15 max | 0.8–1.2 | 0.04–0.35 | 0.25 max | 0.15 max | Remaining |

| 5052 | 0.25 max | 0.4 max | 0.1 max | 0.10 max | 2.2–2.8 | 0.15 max | 0.10 max | 0.20 max | Remaining |

Mechanical Properties (typical, room temperature)

| Alloy-Temper | Tensile Strength (MPa) | Yield Strength 0.2% (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| 5083-O | 275–345 | 125–200 | 12–18 | 60–80 |

| 5083-H111 | 275–365 | 125–215 | 12–16 | 60–85 |

| 5086-H116 | 300–355 | 160–250 | 10–14 | 75–90 |

| 5456-H32 | 320–370 | 200–260 | 10–12 | 80–95 |

| 6061-T6 | 290–310 | 240–275 | 8–12 | 95–115 |

| 5052-H32 | 200–250 | 95–150 | 8–18 | 45–70 |

Typical Dimensional Range & Availability

| Dimension | Typical Range (flat bar) | Notes |

|---|---|---|

| Thickness | 3 mm – 150 mm | Thinner stock below 6 mm often supplied as sheet/plate; heavier sections may be produced as plate/flat-bar |

| Width | 20 mm – 1200 mm | Common widths 25/30/50/100/200/300 mm; custom widths available |

| Length | Up to 12 m or cut-to-length | Standard mill lengths 3–6 m, custom cut-to-length services available |

| Surface | Mill finish, brushed, anodized, coated | Protective films for transport available |

Weldability and Fabrication Notes

- Al-Mg alloys (5083/5086/5456) exhibit excellent fusion weldability with GMAW (MIG) and GTAW (TIG). Use ER5183/ER5356 filler metals depending on alloy and service environment.

- For 6061-T6, expect loss of strength in HAZ; post-weld heat treatment (if possible) or use T4/T6 tempering strategies; ER4043/ER5356 fillers commonly used.

- Avoid excessive preheating for Al-Mg grades; recommended interpass temperatures typically <150°C.

- Bending radii: use minimum internal radius = 1.5–3 × thickness depending on temper and alloy. H-states and strain hardening reduce formability.

- Machining: standard aluminum tooling; use appropriate feeds/feeds to reduce built-up edge; coolant recommended for high-speed cutting.

Corrosion Performance & Protective Strategies

- 5xxx series (Al-Mg) are highly resistant to seawater corrosion; susceptible to stress-corrosion cracking if high strength and cold-work combined — choose H116/H321 tempers or controlled welding procedures to limit risk.

- Cathodic protection, anodizing (for 6xxx), chromate conversion coatings and epoxy/urethane primers improve life in splash and immersion zones.

- Regular rinsing and inspection in heavily fouled or polluted waters recommended.

Quality, Certification & Testing

- Typical documentation: EN 10204 3.1 mill test reports, chemical and mechanical test results.

- Classification: ABS, DNV, Lloyd’s Register, Bureau Veritas approvals available on request for marine-grade product lots.

- Traceability: heat number, batch identification and process records provided on request.

Sample Technical Specification Table (example order)

| Item | Description |

|---|---|

| Product | Marine Aluminum Flat Bar |

| Alloy | 5083-H116 (typical) |

| Thickness | 6 mm |

| Width | 150 mm |

| Length | 4000 mm |

| Tolerance | EN 485 / ASTM B308 applicable tolerances; cut-to-length ±1 mm typical |

| Surface Finish | Mill finish with protective film |

| Mechanical | Tensile 320 MPa; Yield 175 MPa; Elongation 12% |

| Certification | EN 10204 3.1, chemical and mechanical test report |

| Packing | Seaworthy wooden crates, corrosion-inhibitor film, strapping |

Design & Selection Guidance

- Choose 5xxx series for primary hull and structural members exposed to seawater; select temper (H116, H321) when improved SCC resistance is required.

- For parts requiring anodizing and tighter dimensional stability with higher yield strength, consider 6061-T6 but account for lower corrosion resistance in long-term immersion.

- Always match filler metal alloy to base alloy family and intended service; consult supplier for recommended weld consumables and procedures.

- Evaluate fatigue loading (wave slamming, vibration) and specify appropriate thickness and stiffener spacing; aluminum fatigue behavior can be improved via shot peening and surface finish control.

Handling, Storage & Installation

- Protect from galvanic contact with dissimilar metals; use isolation fittings or insulating layers when mating to steel.

- Store in dry, ventilated areas, off the ground, and avoid stacking that traps moisture.

- Avoid contact with iron or steel swarf which can accelerate localized corrosion. Clean surfaces prior to welding or painting.

Environmental & Safety Considerations

- Aluminum is recyclable; specify % recycled content if required by project.

- Dust and fumes: control welding fumes and aluminum dust in fabrication shops per local occupational health standards.

- Disposal: scrap aluminum handled via recycling streams; avoid landfill whenever possible.

Ordering & Customization Options

- Custom lengths, widths, thicknesses, and edge conditions (sheared, saw-cut, milled) available.

- Mill coating, anodizing (6061), or specified primer systems applied prior to delivery.

- Pre-cut holes, notches, and CNC machining available to ship-ready specifications.

- Certification packages, NDT and third-party inspection scheduled on order.

Contact & Further Information

For specific project quotes, alloy/temper recommendations, or to request mill test certificates and classification approvals, contact your marine aluminum supplier with the following project data:

- Vessel type and service (coastal, ferry, offshore support)

- Intended part function (hull stiffener, deck bar, fender)

- Environmental exposure (continuous immersion, splash zone, atmospheric)

- Required standards and classification society approvals

Related Products

Marine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

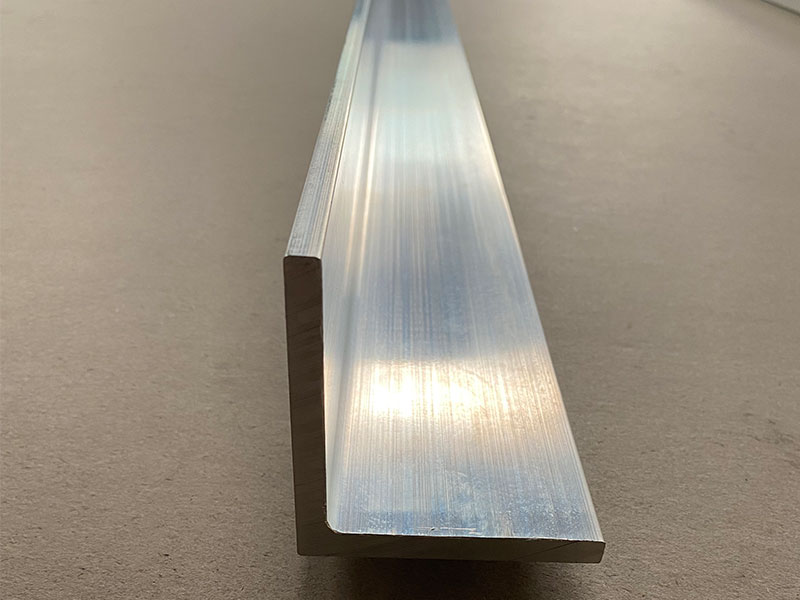

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

5086 Marine Aluminum I Beams for High Strength Marine Engineering

What Makes 5086 Marine Aluminum Special?5086 aluminum alloy is known for its superior corrosion resistance, high anodizing performance, and excellent weldability, making it a popular choice for marine applications.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View DetailsMarine Aluminum Angles for Custom Marine Vessel Deck Parts

In the demanding maritime environment, the structural integrity and durability of vessel deck parts are paramount. Marine aluminum angles have emerged as a critical solution in the customization and reinforcement of these components.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View DetailsMarine Aluminum Z Shaped Sections for Seawater Proof Engineering Solutions

Unmatched advantages of Marine Aluminum Z Shaped Sections in seawater proof engineering solutions. Learn about their technical functions, applications, and why they are indispensable for marine infrastructure.

View Details5083 Marine Aluminum Round Bar for Custom Boat Hull Design

Designing the perfect boat hull involves a harmony of creativity, functionality, and the right materials. When it comes to marine engineering, 5083 Marine Aluminum Round Bar stands tall, due to its strength, corrosion resistance.

View Details

Leave a Message