Marine Aluminum Pipe Elbow for Seawater Reverse Osmosis Units

In the realm of modern water treatment, Seawater Reverse Osmosis (SWRO) units stand as a vital technology for converting seawater into potable water. components within these systems must withstand harsh marine environments, high pressure, and corrosive effects of seawater. One such critical component is the Marine Aluminum Pipe Elbow, a specialty fitting essential for fluid direction changes within SWRO piping networks.

What is a Marine Aluminum Pipe Elbow?

A pipe elbow is a curved fitting used to connect two straight pipes at an angle—commonly 45° or 90°. In the context of SWRO units, pipe elbows direct the high-pressure feedwater or reject brine pipeline flow through tight spaces where pipe layout constraints exist.

Working with marine-grade aluminum, specifically in the context of seawater reverse osmosis (SWRO) units, presents a unique set of challenges and rewards. The elbows we produce for these systems are constantly battling corrosion from the highly saline environment. While our 5052 alloy offers excellent resistance, we constantly monitor for pitting and crevice corrosion, particularly at weld points and internal bends. The manufacturing process needs meticulous attention to detail; even minor imperfections can become nucleation sites for accelerated corrosion, leading to premature failure and costly repairs for our clients. We've learned that precise polishing and passivation after welding is crucial, and ongoing research into novel coatings is a high priority. It's a constant balancing act between material strength, corrosion resistance, and cost-effectiveness.

Beyond the technical aspects, seeing our elbows integrated into a functioning SWRO unit, ultimately providing clean water in a remote location or on a vessel at sea, is deeply satisfying. Knowing our work contributes to sustainable practices and enhances the operational efficiency of these vital systems fuels our dedication. We're not just making pipes; we're contributing to a solution that tackles global water scarcity. That sense of purpose informs our rigorous testing protocols, our commitment to quality control, and our ongoing effort to refine our processes, ultimately ensuring the reliability and longevity of these critical components.

Choosing marine aluminum as the material for these elbows leverages aluminum’s superior corrosion resistance and strength-to-weight ratio in marine conditions, contributing significantly to system reliability in seawater environments.

Primary Functions and Applications in SWRO Units

Marine aluminum pipe elbows serve the following functions in reverse osmosis desalination systems:

Maintaining Hydraulic Efficiency: Diverging the flow precisely at angles ensures minimal turbulence and pressure loss, safeguarding the consistent flow rates essential for optimized RO membrane performance.

Withstanding Corrosive Seawater: The marine aluminum alloy’s excellent resistance limits galvanic corrosion and pitting — typical concerns due to the high chloride content in ocean water.

Pressure Resistance: Designed to tolerate the high inlet pressures (30-70 bar) encountered in SWRO units without deformation, weld failures, or cracking.

Ease of Installation and Maintenance: Lightweight than alternatives like stainless steel, marine aluminum elbows simplify mechanical handling and handling less stress on pipe supports.

Practical installation is common in feedwater intake lines, concentrate reject streams, and permeate flushing applications.

Technical Details and Material Specifications

Typically, marine aluminum pipe elbows are manufactured according to rigorous quality standards ensuring consistency in performance and safety under marine operating conditions.

Common Parameters

| Parameter | Description | Value / Range |

|---|---|---|

| Standard Nominal Size (DN) | Diameter | DN15 - DN200 (depending on usage) |

| Angle | Elbow bend angle | 45°, 90° |

| Pressure Rating | Maximum operational pressure | Up to 100 bar |

| Wall Thickness | Pipe wall per ASTM B209 or similar | Per pipe weight and schedule |

Materials, Alloy Composition & Temper Designation

Marine aluminum elbows are generally alloyed with marine-grade aluminum such as:

- Aluminum Alloy 5083-H321 or 6061-T6, standing out for excellent corrosion resistance and strength, respectively.

Both temper types enhance durability:

- H321 (Strain-hardened then stabilized): Ensures non-aging properties and strength retention during marine operation.

- T6 (Solution heat-treated and artificially aged): A combination offering outstanding mechanical strength suitable for pressurized piping.

Chemical Composition Table (% wt)

| Element | Aluminum 5083-H321 | Aluminum 6061-T6 |

|---|---|---|

| Aluminum (Al) | 94.8 - 96.8% | 97.9% |

| Magnesium (Mg) | 4.0 - 4.9% | 0.8 - 1.2% |

| Manganese (Mn) | 0.4 - 1.0% | 0.15% max |

| Chromium (Cr) | 0.05 - 0.25% | 0.04 - 0.35% |

| Iron (Fe) | ≤ 0.4% | ≤ 0.7% |

| Silicon (Si) | ≤ 0.4% | 0.4 - 0.8% |

| Copper (Cu) | ≤ 0.1% | 0.15 - 0.4% |

| Zinc (Zn) | ≤ 0.25% | ≤ 0.25% |

Implementation Standards

Marine aluminum pipe elbows for SWRO applications should conform to established standards:

- ASTM B241 & ASTM B241M: Aluminum Pipe, Seamless, for General Purpose

- ASTM B209: Aluminum and Aluminum-Alloy Sheet and Plate (for plates used in fabrication)

- ASME B16.9: Factory-Made Wrought Steel Buttwelding Fittings (pipe elbows incl.)

- ISO 7457: Titanium, Zirconium, and Niobium Tube Comprehensive Dimensions – often considered for cross-comparison on dimension tolerances and compatibility

- NACE MR0175 / ISO 15156: For material suitability in conditions of severe corrosiveness (especially relevant for SWRO extreme chemistry)

Related Products

Custom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

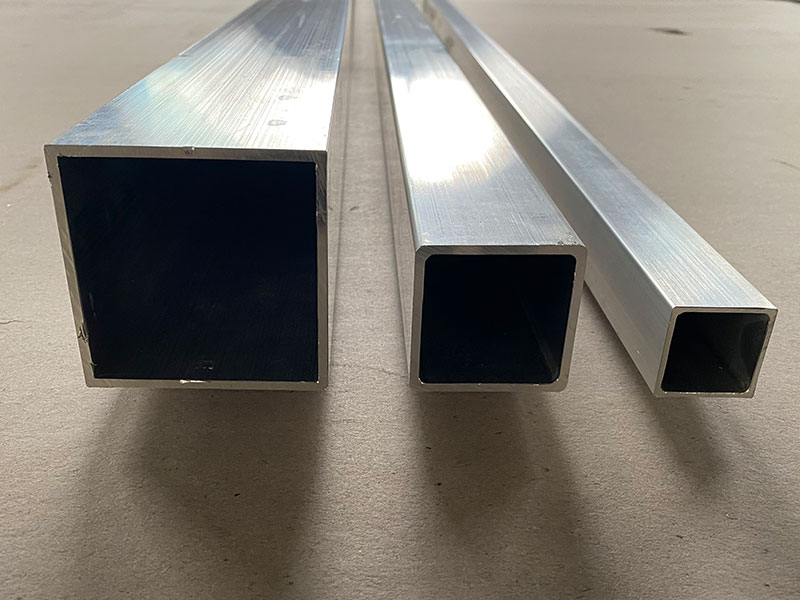

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

Aluminum Elbow for Saltwater Inlet and Outlet Systems

Aluminum elbows play a critical role in saltwater inlet and outlet systems used in marine, industrial, and desalination applications. Manufactured from high-quality aluminum alloys, these fittings are engineered to provide robust, corrosion-resistant.

View DetailsAluminum Elbow for Ship Hot Water and Heating Systems

High-performance Aluminum Elbow designed for ship hot water and heating systems. Featuring optimal corrosion resistance, precise alloy specifications, and industry-standard tempering, this marine-grade fitting ensures durability and superior heat conducti

View Details6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View DetailsMarine Aluminum Elbow for Offshore Oil Spill Containment Systems

Marine Aluminum Elbow for Offshore Oil Spill Containment Systems: Functions, Applications, and Technical InsightsIn the demanding and often harsh environment of offshore oil spill containment systems, every component requires superior performance.

View DetailsMarine Grade Aluminum Pipe Elbow for Offshore Projects

Marine environments pose unique challenges—including corrosion, mechanical stress, and exposure to harsh elements—necessitating the use of specialized materials and components.

View DetailsSeamless Marine Aluminum Elbow for Emergency Ventilation Systems

In the demanding realm of maritime safety and engineering, emergency ventilation systems serve as a cornerstone for onboard operational security and crew welfare.

View Details

Leave a Message