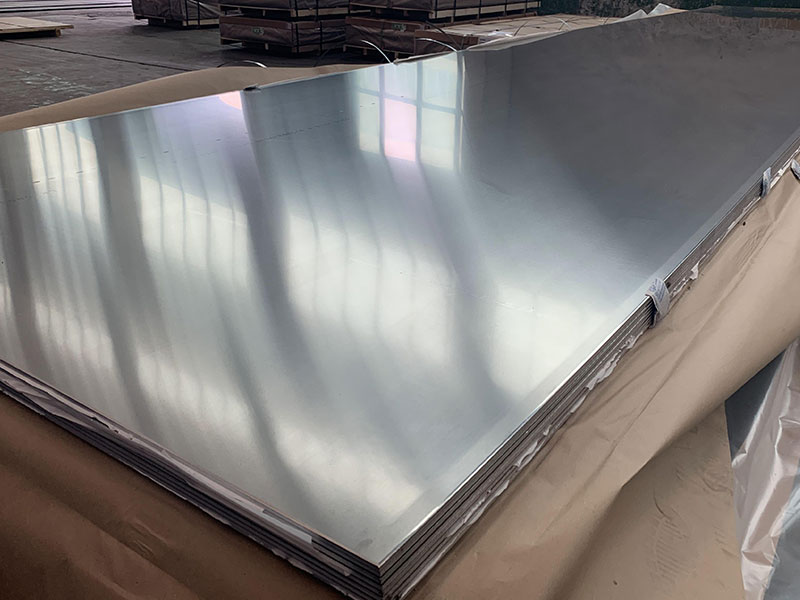

Marine aluminum plate thickness 3mm

Marine aluminum plate thickness 3mm is a highly sought-after material in the maritime industry due to its excellent properties designed to withstand aggressive marine environments. Known for its lightweight, high strength, and excellent corrosion resistance, this type of aluminum plate is widely used for manufacturing ship structures, boat hulls, and various offshore applications.

Features of 3mm Marine Aluminum Plate

| Feature | Description |

|---|---|

| Thickness | 3mm – Ideal for lightweight yet durable marine components |

| Material Grade | Marine-grade aluminum alloys (commonly 5083, 5052, 6061) |

| Corrosion Resistance | Superior resistance to saltwater corrosion and oxidation |

| Strength | High tensile strength, providing durability and structural integrity |

| Weldability | Excellent weldability using common techniques including TIG and MIG welding |

| Formability | Good formability allows bending and shaping without cracking or deformation |

| Lightweight | Reduces overall vessel weight leading to fuel efficiency and better payload capacity |

| Surface Finish | Smooth surface finish, suitable for direct coating or anodizing |

Chemical Composition (%Weight) - Typical Marine Aluminum Alloys

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5083 | 0.4 | 0.4 | 0.1 | 0.4 | 4.0-4.9 | 0.05-0.25 | ≤0.25 | 0.02 | ≤0.15 | Remainder |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15 | ≤0.1 | 0.03 | ≤0.1 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | ≤0.15 | Remainder |

Technical Specifications for 3mm Marine Aluminum Plate

| Parameter | Specification |

|---|---|

| Thickness Tolerance | ±0.1 mm |

| Width | Up to 2200 mm (customizable by customer requirement) |

| Length | Up to 6000 mm or as requested |

| Yield Strength | ≥185 MPa (depending on alloy and temper condition) |

| Tensile Strength | 275 - 350 MPa (varies with alloy) |

| Elongation | 10-22% |

| Density | ~2.66 g/cm³ |

| Hardness | Typically 60 – 90 HRB (talking about annealed and H112 tempers) |

| Surface Finish | Mill finish, brushed finish, or coated options available |

Applications of 3mm Marine Aluminum Plate

The 3mm thick marine aluminum plate’s unique combination of corrosion resistance, durability, and weight advantages lends itself to a broad spectrum of marine and offshore uses, including:

- Boat and Shipbuilding: Used extensively for building hulls, decks, superstructures, and interior compartments where corrosion resistance against seawater is critical.

- Offshore Platforms: Equipped in platforms and structural frameworks exposed to harsh marine environments, providing both strength and marine durability.

- Ship Repairs & Retrofits: Often used in the repair of aging vessels due to its compatibility and ease of welding with original materials.

- Domestic and Commercial Watercraft: Commercial ferries, fishing vessels, and leisure boats use this plate for hulls and decks, balancing performance and longevity.

- Marine Containers & Cargo Boxes: Provides corrosion-resistant and lightweight solutions for containers storing equipment and material used offshore.

- Corrosion-Resistant Architectural Elements: Besides marine uses, its corrosion resistance and aesthetics make it suitable for harbors and waterfront architectural cladding and walkways.

Advantages Over Competing Materials

| Advantages | Marine Aluminum Plate (3mm thickness) | Steel | Other Metals |

|---|---|---|---|

| Corrosion Resistance | High in seawater without coatings | Low without expensive coatings | Depends, often lower corrosion resistance |

| Weight | Approx. 1/3 weight of steel | Heavy | Varies |

| Weldability | Excellent (TIG, MIG) | Good but requires caution | Variable |

| Ease of Fabrication | Highly formable and workable | Heavier and harder to form | Dependent on metal |

| Cost Efficiency | Moderate; savings on maintenance and fuel | Sometimes cheaper initial cost but expensive long term | Usually higher or niche applications |

A 3mm thick marine aluminum plate offers an excellent balance of performance parameters tailored especially for maritime environments. Its lightness, corrosion resistance, and fabrication ease contribute to increased efficiency and cost savings during fabrication and service life. Whether employed in shipbuilding, repairs, offshores or specialized projects, this marine-grade aluminum sheet serves as an indispensable material solution.

Choosing a marine aluminum plate at 3mm thickness from dependable suppliers ensures compliance with required technical and quality standards to achieve optimum fleet performance and asset durability within your marine projects.

Related Products

Marine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsRelated Blog

5052 h111 alloy aluminum marine plate

When it comes to marine aluminum plates, performance and reliability are non-negotiable qualities due to the challenging environments they encounter—saltwater corrosion, fluctuating temperatures, and mechanical stresses.

View DetailsMarine Grade 5083, 5082 Aluminum Alloy Sheet Plate

When it comes to materials that perform exceptionally under the harsh conditions of marine environments, Marine Grade aluminum alloys like 5083 and 5082 hold a revered place in the industry’s toolkit.

View Details5083 marine grade aluminium plate for ship building

5083 Marine Grade Aluminium Plate: The Backbone of Modern ShipbuildingWhen it comes to building durable, efficient, and lightweight vessels, 5083 marine grade aluminium plate stands out as a premier material choice.

View Details5083 marine aluminum sheet plate

5083 marine aluminum sheet plate has established itself as a standard reference in the maritime industry, thanks to its exceptional combination of performance, versatility, and durability.

View Details11 mm thick marine aluminium plate 5083

Marine industries demand materials that offer exceptional strength, corrosion resistance, and durability under harsh environmental conditions. The 11 mm thick marine aluminium plate 5083 is specifically designed to meet these rigorous standards.

View Details5083 H116 marine grade aluminum alloy sheet plate

Superior corrosion resistance and high strength of 5083 H116 marine grade aluminum alloy sheet plate. Ideal for shipbuilding and marine structures, this alloy ensures durability in harsh sea conditions with excellent weldability and excellent workability.

View Details

Leave a Message