Marine Aluminum Rod & Bar for Offshore Marine Project Design

Marine aluminum rod and bar products are core structural and functional materials in offshore and shipbuilding projects. They combine high strength, excellent corrosion resistance, and low weight, making them ideal for harsh saltwater environments where durability and safety are critical.

1. Why Marine Aluminum Rod & Bar?

Marine aluminum alloys—typically from the 5xxx (Al–Mg) and 6xxx (Al–Mg–Si) series—are specifically engineered for long-term exposure to seawater, wave loading, and cyclic stresses.

Core Advantages

- High corrosion resistance in seawater and splash zones

- Lightweight: about one-third the density of steel

- Good specific strength: high strength-to-weight ratio

- Excellent weldability and machinability

- Non-magnetic and spark-resistant (for many offshore environments)

- Good toughness at low temperatures (critical for offshore climates)

These properties make marine aluminum rod and bar particularly attractive for offshore platforms, ship fittings, subsea hardware, and coastal infrastructure.

2. Typical Marine Alloys for Rod & Bar

The most common marine aluminum alloys for rod and bar include:

- 5xxx Series (Al–Mg): 5052, 5083, 5086, 5454, 5456

- 6xxx Series (Al–Mg–Si): 6061, 6082

Recommended Alloys by Application Focus

| Alloy | Series | Primary Strength | Corrosion Resistance in Seawater | Weldability | Typical Usage Focus |

|---|---|---|---|---|---|

| 5052 | 5xxx | Medium | Very good | Excellent | General marine hardware, brackets |

| 5083 | 5xxx | High | Excellent | Very good | Hull structures, highly stressed parts |

| 5086 | 5xxx | High | Excellent | Very good | Hulls, deck structures |

| 5454 | 5xxx | Medium–High | Very good | Very good | Tanks, piping, structural members |

| 5456 | 5xxx | High | Very good | Good | High-strength structural applications |

| 6061 | 6xxx | Medium–High | Good–Very good | Very good | Machined components, fittings |

| 6082 | 6xxx | High | Good–Very good | Good | Load-bearing bars, machined parts |

Note: Slotting the correct alloy to each project is essential; 5xxx is favored for direct seawater exposure, 6xxx where high mechanical strength and machining precision dominate.

3. Example Chemical Composition (Typical Ranges)

Below is a representative chemical composition for two widely used marine alloys used for rods and bars: 5083 (high-strength marine structural) and 6082 (high-strength, machinable).

Alloy 5083 (Marine-Grade, Rod & Bar)

| Element | Typical Range (wt. %) |

|---|---|

| Mg | 4.0 – 4.9 |

| Mn | 0.4 – 1.0 |

| Cr | 0.05 – 0.25 |

| Si | ≤ 0.40 |

| Fe | ≤ 0.40 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Al | Balance |

Alloy 6082 (Heat-Treatable, Rod & Bar)

| Element | Typical Range (wt. %) |

|---|---|

| Mg | 0.6 – 1.2 |

| Si | 0.7 – 1.3 |

| Mn | 0.4 – 1.0 |

| Fe | ≤ 0.50 |

| Cu | ≤ 0.10 |

| Cr | ≤ 0.25 |

| Zn | ≤ 0.20 |

| Ti | ≤ 0.10 |

| Al | Balance |

The magnesium content in 5xxx alloys provides solid-solution strengthening and excellent corrosion resistance, while the Mg–Si phase in 6xxx alloys allows heat treatment for higher strength.

4. Mechanical & Physical Properties

Properties depend on alloy and temper. The table below shows typical values at room temperature for common marine rod/bar materials.

Typical Mechanical Properties (Indicative)

| Property | 5083-O / H111 | 5083-H116/H321 | 6082-T6 |

|---|---|---|---|

| Tensile Strength, Rm (MPa) | 270 – 330 | 305 – 345 | 295 – 340 |

| Yield Strength, Rp0.2 (MPa) | ≥ 125 | ≥ 215 | ≥ 240 |

| Elongation (A50, %) | 16 – 20 | 12 – 16 | 8 – 12 |

| Brinell Hardness HB | ~75 – 85 | ~85 – 95 | ~95 – 110 |

Physical Properties

| Property | Typical Value (Al-Mg/Al-Mg-Si) |

|---|---|

| Density | ~2.66 – 2.72 g/cm³ |

| Modulus of Elasticity | ~69 – 72 GPa |

| Coefficient of Thermal Expansion | ~23–24 ×10⁻⁶ /K |

| Thermal Conductivity | 120 – 170 W/m·K |

| Electrical Conductivity | 30 – 40 % IACS |

The low density combined with reasonable strength leads to significant weight reduction relative to steel, which directly translates into lower installed mass, reduced fuel consumption for vessels, and easier handling offshore.

5. Corrosion & Fatigue Performance

Aluminum’s natural oxide film provides intrinsic corrosion resistance. In marine alloys, the optimized Mg and low Cu levels enhance this protection, particularly in chloride-rich seawater.

Corrosion & Fatigue Highlights

| Performance Aspect | Behavior in Marine Service |

|---|---|

| General seawater corrosion | Very good to excellent (5xxx best-in-class) |

| Pitting & crevice corrosion | Low, especially with proper design & cathodic control |

| Stress corrosion cracking | Very low in 5xxx; well-managed in 6xxx with design |

| Fatigue strength | Good; improved via smooth surface, low notch severity |

| Galvanic compatibility | Good when insulated from less noble metals (e.g. steel) |

Proper design—avoiding stagnant crevices, controlling bimetallic couples, and adhering to good welding practice—greatly extends life in the splash and tidal zones.

6. Standard Product Range & Technical Specifications

Marine aluminum rod and bar can be supplied in various dimensions and tempers tailored to design needs.

Typical Dimensional Range

| Product Type | Shape Options | Typical Size Range |

|---|---|---|

| Rod | Round | Ø 6 – 300 mm (larger on request) |

| Bar | Flat, square, hexagonal | 10 × 10 mm up to 200 × 50 mm+ |

| Custom | Hollow, stepped, profiled | Based on drawing and tooling |

Available Tempers (Common Examples)

| Alloy | Typical Tempers for Marine Rod & Bar | Notes |

|---|---|---|

| 5052 | O, H32, H34 | Balanced strength and formability |

| 5083 | O, H111, H116, H321 | Marine-class for long-term seawater exposure |

| 5086 | O, H112, H116, H32 | High strength in hull and deck systems |

| 5454 | O, H32, H34 | Tanks & piping with elevated temperature use |

| 6061 | T6, T651, T6511 | Precision-machined structural components |

| 6082 | T6, T651, T6511 | High strength and machinability for bars |

Example Technical Specifications & Standards

| Category | Typical Standards / Specifications |

|---|---|

| Material standard | ASTM B211, ASTM B221, EN 573, EN 755 |

| Marine approvals | DNV, ABS, LR, BV (project-specific basis) |

| Welding standards | ISO 9606, ISO 15614, AWS D1.2 |

7. Processing & Fabrication

Marine aluminum rod & bar are optimized for ease of fabrication.

Fabrication Characteristics

| Process | Performance & Notes |

|---|---|

| Cutting | Sawing, waterjet, plasma; minimal burr with proper tooling |

| Machining | Good to excellent (6xxx superior for precision parts) |

| Welding | MIG, TIG widely used; 5xxx alloys weld exceptionally |

| Forming/Bending | Good cold formability, especially O/H111 tempers |

| Surface Prep | Can be anodized, painted, or coated for extra protection |

This flexibility enables efficient manufacture of complex offshore components and rapid adaptation to design changes.

8. Typical Applications in Offshore & Marine Projects

Marine aluminum rod and bar feature in a wide range of offshore and coastal structures:

Offshore Oil & Gas / Wind

- Handrails, guardrails, and ladder systems

- Cable trays, supports, and brackets

- Fasteners, pins, clevises, and connectors

- Light structural frames and mast sections

- Instrumentation stands and support arms

Shipbuilding & Workboats

- Deck fittings: bollards, chocks, fairleads (with proper design)

- Hinges, handles, and rail stanchions

- Structural stiffeners and localized reinforcements

- Steering linkages, rudder components (non-primary)

Coastal & Harbor Infrastructure

- Floating pontoon frames and connections

- Gangways, ramps, and access bridges

- Fender backing bars and hardware

- Corrosion-resistant fixtures in marinas and terminals

Subsea & Special Equipment

- Non-magnetic housings and frames

- Lightweight subsea structures in protected environments

- Frames for ROV tools or sensor arrays (with suitable protection)

9. Benefits for Offshore Project Designers

For project engineers and naval architects, the value of marine aluminum rod & bar is tangible across design, construction, and service life:

| Benefit Category | Impact on Project |

|---|---|

| Weight reduction | Smaller crane requirements, reduced vessel displacement, lower operating fuel cost |

| Corrosion resistance | Long service life, lower maintenance, fewer recoating cycles |

| Fabrication speed | Easier cutting/welding/machining vs stainless steel; shorter turnaround times |

| Safety & reliability | Good fatigue resistance; non-sparking and non-magnetic for certain applications |

| Lifecycle cost | Lower total cost of ownership despite higher material unit cost |

Designers can often simplify structural details, reduce the need for heavy corrosion allowance, and standardize components across multiple platforms or vessels.

Marine aluminum rod and bar are high-performance materials designed to withstand demanding offshore and marine environments. By selecting appropriate alloys and tempers—commonly 5083/5086/5456 for direct seawater exposure and 6061/6082 for precision-machined, high-strength parts—designers can achieve:

- Durable, corrosion-resistant structures

- Significant weight savings

- Flexible, cost-effective fabrication

- Reliable service over long design lives

When integrated thoughtfully into offshore and marine systems, marine aluminum rod & bar deliver a strong balance of performance, safety, and lifecycle economy.

Related Products

6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

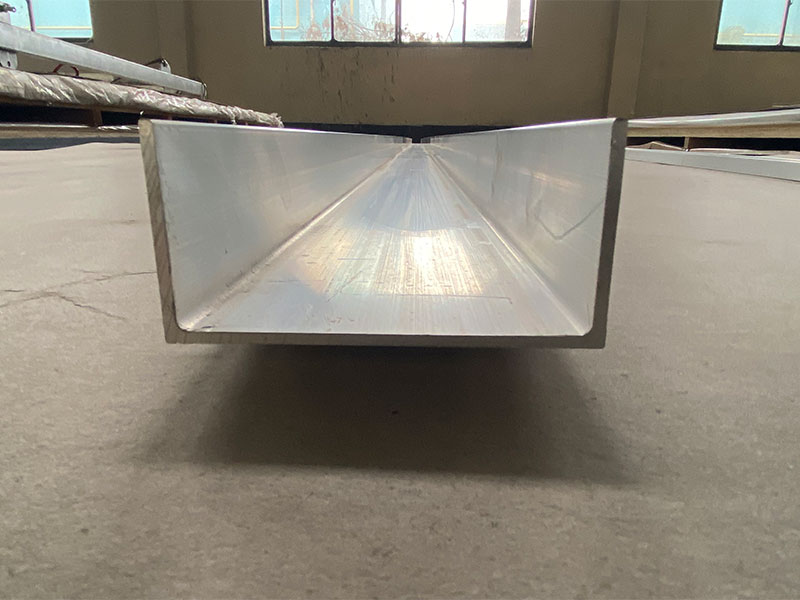

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

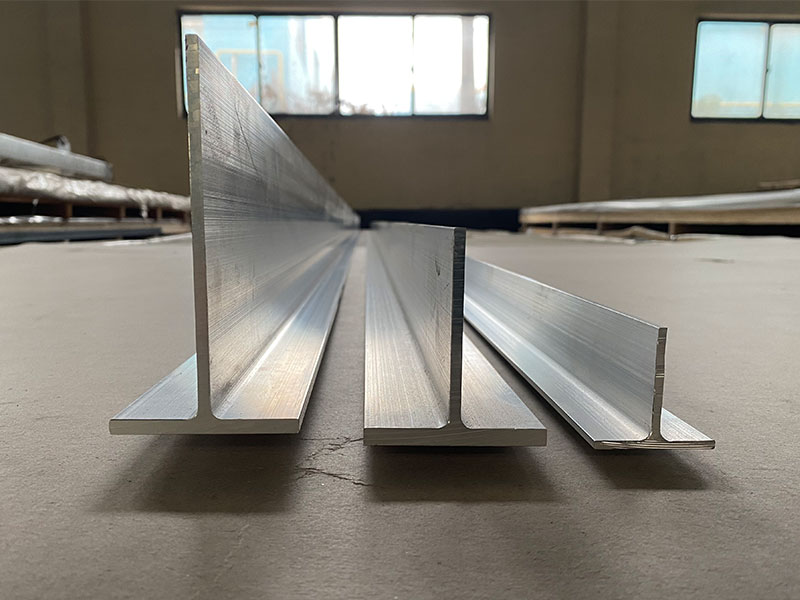

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details6061 Marine Aluminum Z Shaped Sections for Saltwater Resistant Engineering

In the world of marine construction, material selection is critical for ensuring durability, strength, and resistance to harsh environmental conditions.

View Details5083 Marine Aluminum Round Bar for Custom Boat Hull Design

Designing the perfect boat hull involves a harmony of creativity, functionality, and the right materials. When it comes to marine engineering, 5083 Marine Aluminum Round Bar stands tall, due to its strength, corrosion resistance.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details5052 Marine Aluminum Angles for Heavy Duty Marine Applications

In the world of marine applications, the choice of materials can significantly influence performance and longevity. For heavy-duty usage, marine aluminum angles, particularly 5052 Marine Aluminum angles, come out as premier contenders.

View Details

Leave a Message