Aluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116, and H32 are commonly employed grades that deliver an excellent blend of mechanical properties and corrosion resistance, essential for harsh marine environments.

Aluminum Alloy 5083 is a non-heat-treatable alloy primarily composed of aluminum, magnesium, and trace amounts of manganese and chromium. Known for outstanding corrosion resistance, particularly to seawater and industrial chemicals, it offers superior strengthening through strain hardening.

| Property | Value |

|---|---|

| Al Content (%) | Balance (~95%) |

| Magnesium (Mg) (%) | 4.0 - 4.9 |

| Manganese (Mn) (%) | 0.4 - 1.0 |

| Chromium (Cr) (%) | 0.05 - 0.25 |

| Density (g/cm³) | 2.66 |

| Melting Point (°C) | ~590 |

Characteristics of Aluminum 5083 Sheets

1. Corrosion Resistance

- High resistance to saltwater corrosion makes it ideal for marine applications.

- Resists chloride ions and salt spray, making it resilient in harsh marine atmospheres or shipbuilding environments.

2. Strength and Toughness

- Magnesium reinforcement provides elevated strength while completing toughness.

- Retains strength and ductility at sub-zero temperatures.

- Wide range of konnteformance grades (mantled by the tempering process) permit customized solutions balancing formability and strength.

3. Weldability and Formability

- Excellent weldability by all commonly used methods: TIG, MIG, spot welding.

- Good cold formability allows detailed shaping and panel forming without incipient cracking.

- H111 & H112 display favorable cold working characteristics but differ in degree of strain hardening.

Explanation of Common Tempers

| Temper | Description | Hardness (Brinell, HB) | Typical Tensile Strength (MPa) | Elongation (%) at Break |

|---|---|---|---|---|

| H111 | Strain-hardened but less than H11, slightly softer | ~68 - 72 | 250 - 310 | 10 - 14 |

| H112 | Strain hardened and stabilized to resist annealing | Slightly higher than H111 | 270 - 320 | 10 - 14 |

| H116 | Specifically thermally treated for marine service | Similar to H112 | 270 - 320 | 10 - 14 |

| H32 | Strain hardened to quarter hard level | Medium hard (~79 - 85) | 320 - 360 | 8 - 12 |

Typical Mechanical Properties by Temper (5083 Alloy)

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| H111 | 250 - 290 | ≥ 120 | ≥ 14 | 68 - 72 |

| H112 | 270 - 310 | ≥ 135 | ≥ 14 | 72 - 78 |

| H116 | 270 - 310 | ≥ 135 | ≥ 14 | 72 - 78 |

| H32 | 320 - 360 | ≥ 240 | 8 - 12 | 79 - 86 |

Applications in Boat Construction

Using 5083 aluminum sheets with the specified tempers enhances component performance in the following marine-grade structures:

- Hull Plates: The superior corrosion resistance and good ductility make 5083 sheets ideal for hull plating, able to endure seawater and constant stress.

- Deck Structures: Temper variants like H116 and H32 provide higher mechanical strength to resist impact and abrasion on deck surfaces.

- Superstructures & Topsides: Formable H111-H112 tempers allow complex shaping for structures above the waterline with adequate strength.

- Fuel Tanks & Storage Compartments: Resistance to corrosion by a variety of fluids reduces maintenance overhead and protects integrity.

- Rigging and Fishing Vessels: The toughness in colder temper ranges secures performance in varied climates including icy waters.

- Other Applications: Aluminum 5083 sheets also extend to lightweight transportation trailers, pressure vessels, and general marine hardware components requiring durable, corrosion-resistant material.

Advantages for Boating Industry

- Light Weight: Critical for vessel speed, fuel efficiency, and payload optimization.

- Maintenance Cost Reduction: Resistant to oxidation and galvanic corrosion reduces repair and overhaul downtime.

- Safety: Enhanced impact resistance keeps structural integrity during collisions or grounding.

- Longevity: Bottom line warranty of service lifetime often exceeds that of competing materials like mild steel or fiberglass.

Related Products

Marine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsRelated Blog

5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View DetailsAluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance.

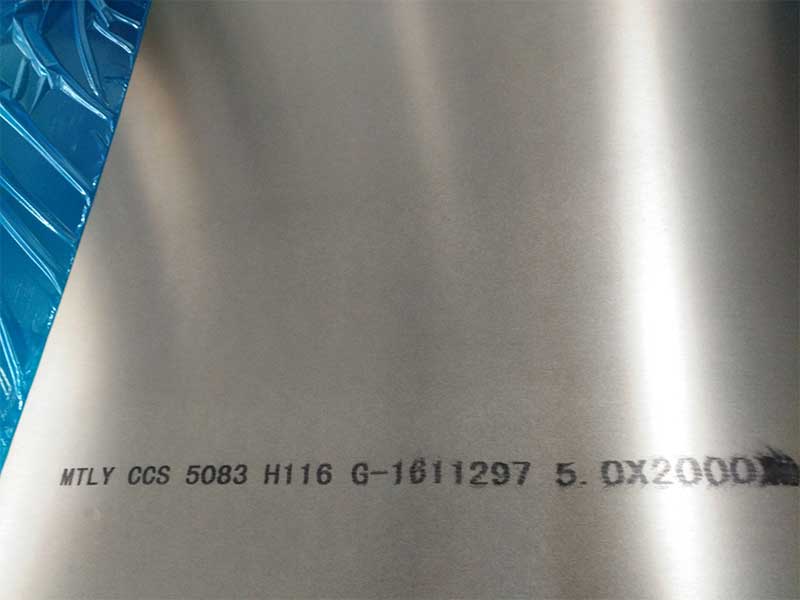

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View Details5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile ApplicationsIn the realm of marine engineering, material selection determines durability, safety, and performance.

View DetailsAluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116.

View Details

Leave a Message