6061 Marine Aluminum Tubes for Offshore Platform Design and Construction

In the harsh environment of offshore platforms, material selection plays a pivotal role in ensuring structural integrity, longevity, and safety. Marine aluminum, especially 6061 marine aluminum tubes, has become a go-to material due to its excellent combination of strength, corrosion resistance, and workability.

Functions of 6061 Marine Aluminum Tubes

6061 aluminum alloy is renowned for its outstanding mechanical properties and high corrosion resistance, especially in marine environments. The tubing made from this alloy serves several crucial functions in offshore construction:

- Structural Support: It offers high-strength support ideal for framing, railings, and other structural components that require weight durability without excessive bulk.

- Corrosion Resistance: The alloy’s composition provides robust resistance against saltwater corrosion, which is essential for maintaining structural integrity over prolonged periods.

- Lightweight Construction: Compared to steel alternatives, 6061 aluminum tubes significantly reduce overall structure weight while maintaining strength, facilitating easier installation and reducing transportation costs.

- Fabrication Versatility: The excellent machinability and weldability of 6061 allow for easy customization and adaptability in complex offshore platform designs.

Applications in Offshore Platform Design and Construction

In offshore environments, 6061 aluminum tubes serve various vital roles:

- Pipeline Supports: Acting as conduits or supports for pipelines transporting fluids or gases.

- Structural Frames: Used in fabricating supporting frameworks for equipment, shelters, and walkways.

- Handrails and Guardrails: Critical for safety, offering corrosion-resistant and durable safety barriers.

- Marine Equipment Housings: Protective enclosures for instrumentation and sensitive equipment, benefiting from aluminum’s non-sparking and corrosion-resistance properties.

- Subsea Connection Components: Supporting subsea connectors and junctions, where strength and corrosion resistance are required under water pressure conditions.

Technical Parameters and Compliance Standards

| Parameter | Value / Specification |

|---|---|

| Alloy Code | 6061-T6 / 6061-T651 |

| Form | Tubes (Seamless and Welded) |

| Density | 2.70 g/cm³ |

| Tensile Strength | 290 - 310 MPa |

| Yield Strength | 240 - 280 MPa |

| Elongation at Break | ≥10% |

| Young’s Modulus | approximately 69 GPa |

| Corrosion Resistance | Excellent in marine environment |

| Thermal Conductivity | ~167 W/mK (at 25°C) |

| Electrical Conductivity | about 40 % IACS |

| Typical Tube Diameters | 10 mm to 200 mm |

| Tube Wall Thickness | 1 mm to 15 mm |

| Manufacturing Standards | ASTM B 210 (Seamless), ASTM B 221 (Welded) |

Chemical Composition of 6061 Marine Aluminum

6061 alloy consists primarily of aluminum mixed with alloying elements to optimize performance. Below is the typical concentration of its chemical constituents expressed in weight percentage (wt.%):

| Element | Typical Content (wt.%) |

|---|---|

| Aluminum (Al) | Balance (Approx. 97.9 - 98.6) |

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.4 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Manganese (Mn) | ≤ 0.15 |

| Titanium (Ti) | ≤ 0.15 |

| Others | ≤ 0.05 each |

Alloy Tempering Conditions

6061 tubes are typically supplied in temper conditions that enhance mechanical properties depending on expected offshore application needs:

| Temper | Description | Properties |

|---|---|---|

| T6 | Solution heat-treated and artificially aged | Excellent mechanical strength and moderate corrosion resistance |

| T651 | Solution heat-treated, stress-relieved by stretching, then artificially aged | Preferred for minimizing distortion during fabrication and providing dimensional stability |

| F (As Fabricated) | No special thermal processing after forming | Lower strength, higher ductility |

For marine applications, T6 and T651 are the most commonly utilized tempers due to balanced strength, corrosion resistance, and dimensional stability requirements.

Advantages of 6061 Marine Aluminum Tubes over Other Materials

Comparative performance of 6061 marine aluminum tubes makes them superior in multiple facets versus conventional materials such as stainless steel or carbon steel:

| Aspect | 6061 Marine Aluminum | Stainless Steel | Carbon Steel |

|---|---|---|---|

| Density | 2.70 g/cm³ (lightweight) | ≈7.8 g/cm³ (heavy) | ≈7.85 g/cm³ (heavy) |

| Corrosion Resistance | Excellent, especially in saltwater | High | Poor without coatings |

| Strength to Weight | High | High but heavier | Moderate |

| Workability | Easy to machine and weld | Difficult and costly | Moderate |

| Cost | Moderate | Expensive | Low |

Related Products

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

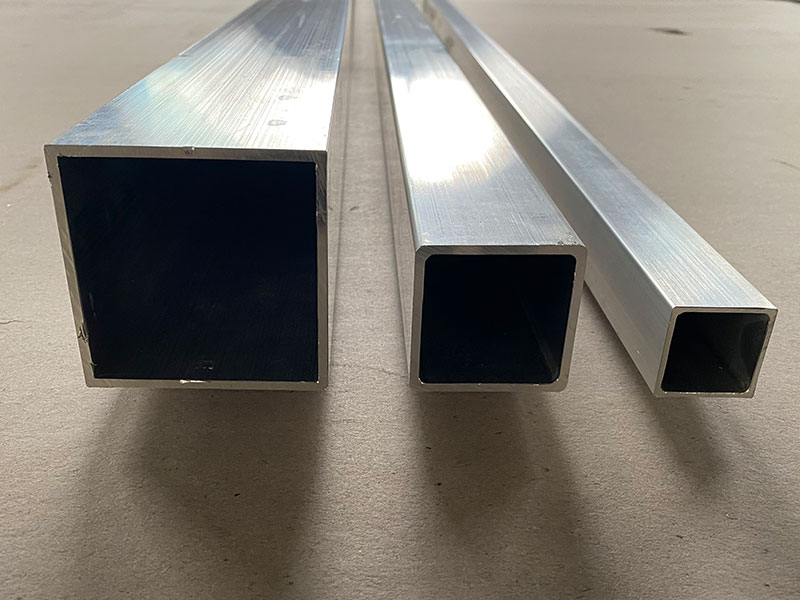

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details6061 Marine Aluminum Tubes for Commercial Marine Vessels

In the realm of commercial marine construction, choosing the right materials is paramount. Among the best options, 6061 marine aluminum tubes have become the undeniable standard for their balance of strength, lightweight, and corrosion resistance.

View Details6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View Details6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals.

View Details6061 Marine Aluminum Tubes for Marine Machinery Support Systems

6061 Marine Aluminum Tubes: Essential for Marine Machinery Support SystemsIn the complex machinery and construction of the marine industry, the materials crafted for durability and management play a pivotal role.

View Details

Leave a Message