5083 Marine Aluminum Tubes for Coastal Boat Building

Marine Aluminum is a prominent material in the marine industry due to its exceptional properties, which makes it the perfect choice for constructing strong, lightweight vessels. One alloy that stands out in coastal boat building is 5083 marine aluminum.

Functions of 5083 Marine Aluminum Tubes

5083 marine aluminum tubes are specially designed to withstand the harsh conditions of marine environments. functions include:

- Corrosion Resistance: 5083 no. 1 alloy is recognized for its superior corrosion resistance in saltwater, ensuring longevity for marine applications.

- Weight-Saving: The lightweight nature of aluminum reduces overall vessel weight, enhancing performance and fuel efficiency.

- Versatility: The alloy's formability allows it to be manufactured in various shapes and sizes suitable for structural and aesthetic purposes in boatbuilding.

- Weldability: 5083 can be easily welded, enabling repair and redesign options commonly applied in boat construction and refurbishments.

Applications of 5083 Marine Aluminum Tubes

Supports various marine structures including:

- Boat Hulls and Superstructures: Ideal for constructing the hulls and superstructures due to high tensile strength.

- Railings and Frames: Lightweight and robust perfect for railings, frames, and additional structural components.

- Floating Structures: Used in designs requiring reduced weight without compromising strength, such as flotation devices and pontoons.

Technical Details of 5083 Marine Aluminum Tubes

To give a complete of 5083 marine aluminum tubes, it is essential to include alloy tempering conditions and chemical properties. This crucial data ensures compliance with industry standards and highlights the material's efficacy in marine applications.

Chemical Composition

The following table outlines the typical chemical composition of 5083 aluminum:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Copper (Cu) | ≤ 0.1 |

| Chromium (Cr) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

| Silicon (Si) | ≤ 0.4 |

| Iron (Fe) | ≤ 0.4 |

Technical Specifications

| Property | Specification |

|---|---|

| Yield Strength (MPa) | ≥ 240 |

| Ultimate Tensile Strength (MPa) | 320 - 360 |

| Density (g/cm³) | 2.66 |

| Elongation (%) | 10-12 |

| Hardness (Brinell) | 80 |

Alloy Tempering Conditions

The tempering conditions given below suggest the heat treatment appropriate for 5083 marine aluminum:

| Temper Parameter | Condition | Remark |

|---|---|---|

| Solution Heat Treatment | 580°C, 1 hour, air cool | Improves strength |

| Aging | 160°C, 8 hours | Optimizes strength without reducing ductility |

Compliance and Standards

Parts constructed from 5083 marine aluminum tubes must comply with maritime safety and design standards such as:

- MIL-STD-414: Military specification for consistent part quality.

- EN 755-9: Standard for the mechanical properties of extruded aluminum profiles.

- DNV GL Rules for Classification of Ships: Guidelines that ensure marine structures can safely withstand designed loads.

Reliability and resilience are cornerstones when constructing coastal vessels, especially in demanding marine environments. 5083 marine aluminum tubes is know for their low density, high strength, corrosion resistance, and excellent weldability, making them an indispensable material in modern boat building.

When considering materials for vessel construction, it is crucial to understand the detailed makeup blueprints, demonstrating why 5083 marine aluminum offers unrivaled performance across various applications in the marine industry.

This comprehensive evaluation sheds light on how 5083 marine aluminum tubes create stable, effective solutions for building retainable, overall structural efficiency and baseline reliability on coastal waters.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

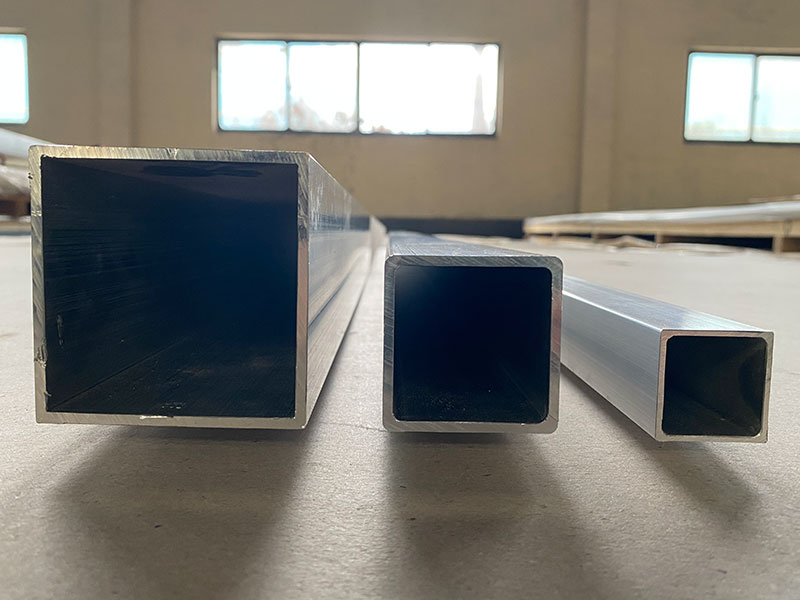

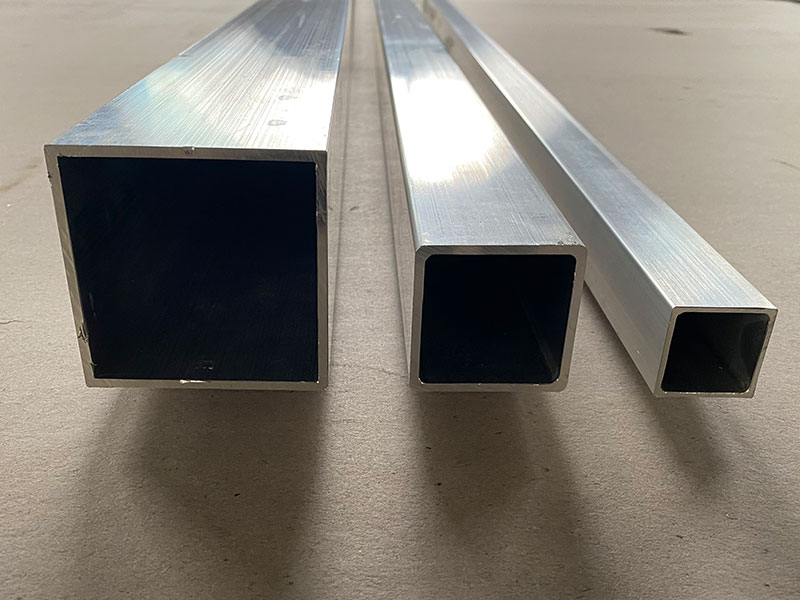

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details5083 Marine Aluminum Tubes for Marine Hull Construction

5083 aluminum alloy is one of the most widely used non-heat-treatable marine alloys. Designed for superior corrosion resistance, high strength, and excellent weldability, 5083 tubes are ideal for hull structures, superstructures, piping.

View Details5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

View Details

Leave a Message