5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice, especially for making marine aluminum tubes designed to withstand harsh saltwater environments.

5083 is an aluminum-magnesium alloy, manufactured primarily for its exceptional corrosion resistance, especially in marine and saltwater environments. Its alloying and temper treatment give it superior strength while retaining light weight and weldability.

Chemical Composition of 5083 Aluminum

| Element | Content (wt %) |

|---|---|

| Aluminum | Balance |

| Magnesium | 4.0 – 4.9 |

| Manganese | 0.4 – 1.0 |

| Chromium | 0.05 – 0.25 |

| Iron | ≤ 0.4 |

| Silicon | ≤ 0.4 |

| Copper | ≤ 0.1 |

| Zinc | ≤ 0.25 |

| Other | ≤ 0.15 |

Magnesium and manganese are the elements that give 5083 alloy its strength and resistance.

Physical and Mechanical Properties

5083 aluminum tubes balance strength and toughness with excellent corrosion resistance. Below you can find its standard mechanical properties for common tempers, primarily H111 and H321.

Working with 5083 marine aluminum tubes in our factory, I've observed that their saltwater durability hinges heavily on factors beyond just the alloy composition. Proper surface preparation before any coating or fabrication is paramount. We've seen instances where inadequate cleaning, leading to residual contaminants like chlorides, significantly accelerated corrosion even with high-quality protective coatings. Similarly, consistent and thorough anodizing is crucial; uneven application creates weak points vulnerable to pitting and crevice corrosion. Furthermore, the forming processes themselves can introduce micro-cracks or stress points, making these tubes susceptible to premature degradation in the harsh marine environment. Therefore, our quality control procedures meticulously monitor each stage, from raw material inspection to final testing, ensuring consistent high performance.

Beyond the production line, the specific application is to maximizing tube lifespan. Factors like the water's salinity, temperature fluctuations, and the presence of other corrosive agents (e.g., biofouling) dramatically affect the corrosion rate. We often advise clients on proper installation techniques, emphasizing considerations like minimizing contact with dissimilar metals (galvanic corrosion) and ensuring sufficient drainage to prevent stagnant water buildup. A case study involving a client's offshore platform highlighted the importance of this: tubes improperly installed suffered significantly accelerated corrosion compared to correctly installed counterparts, demonstrating that even the highest-quality 5083 aluminum demands careful consideration within the overall system design for long-term success in a saltwater environment.

| Property | Typical Values |

|---|---|

| Density | 2.66 g/cm³ |

| Melting Range | 590 – 650 °C |

| Ultimate Tensile Strength (Rm) | 275 – 350 MPa (varies by temper) |

| Yield Strength (Rp0.2) | 125 – 215 MPa |

| Elongation at Break | 10 – 16% |

| Modulus of Elasticity | ~70 GPa |

| Thermal Conductivity | ~130 W/mK |

| Electrical Conductivity | 29 – 35% IACS |

Features of 5083 Marine Aluminum Tubes

Superior Corrosion ResistanceThe high magnesium content combined with manganese reinforces this alloy’s ability to resist pitting, cracking, and corrosion from saltwater exposure, outperforming most other commercial aluminum alloys.

Strong and Yet LightweightWhile classic marine grade steels are heavier and liable to rust, 5083 tubes offer a lighter solution without compromising on strength or durability.

Excellent Weldability5083 aluminum melts cleanly and bonds well with standard welding methods; this simplifies fabricating intricate tube assemblies onboard ships and offshore structures.

Non-Magnetic and Non-ToxicThese attributes enhance applications demanding minimal interference with electronics and ensure environmentally friendly marine operations.

Good Low-Temperature PerformanceMaintains its strength and ductility even at subzero temperatures typical of cold marine environments.

Applications of 5083 Marine Aluminum Tubes

Marine & Shipbuilding Industry

- Boat frames and hulls: 5083 alloy tubes ensure a sturdy, corrosion-resistant framework, improving lifespan and reducing maintenance.

- Railings and safety barriers: Lightweight and resilient fittings are imperative for safety on deck without adding undue weight.

- Offshore platforms and rigs: High-performance tubing resists corrosion and mechanical stresses from constant saltwater exposure.

Transportation

- Trailer frames: Especially boat trailer frames where combined saltwater exposure and structural load require both corrosion resistance and strength.

- Chemical tankers & pipelines: Tubular forms can propel fluid transport with rust free and lightweight advantages.

Industrial and Structural Uses

- Architectural outdoor furnitureExposure to marine environments and humidity calls for corrosion-resistant construction materials.

- Renewable energy infrastructureUsed in tidal and offshore wind turbine mounts and supports exposed to seawater spray.

Why Choose 5083 Aluminum Tubes for Your Marine Projects?

| Criteria | 5083 Aluminum Tubes |

|---|---|

| Saltwater Corrosion Resistance | Excellent (marine grade standard) |

| Weight Efficiency | Up to 70% lighter than steel |

| Strength | High structural strength for frame tubes |

| Fabrication Flexibility | Easy to weld and machine |

| Lifecycle Maintenance | Lower cost due to reduced corrosion |

Related Products

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

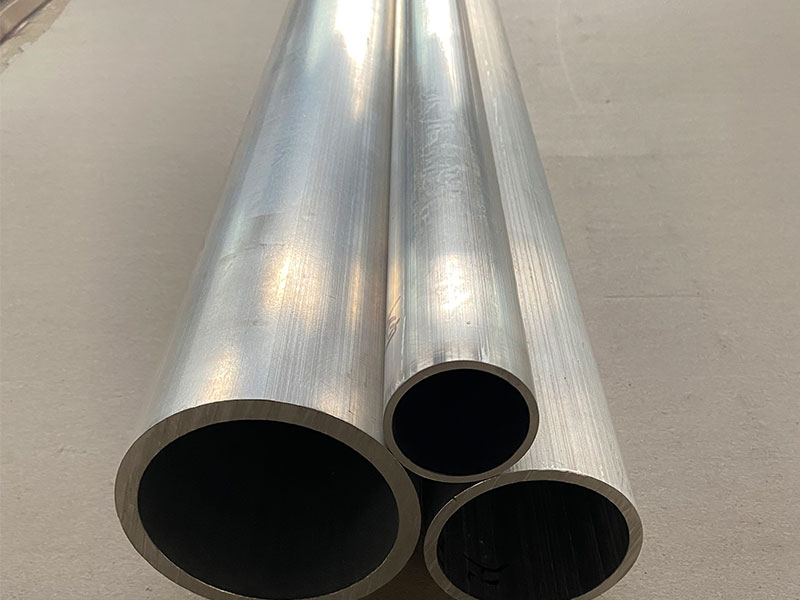

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

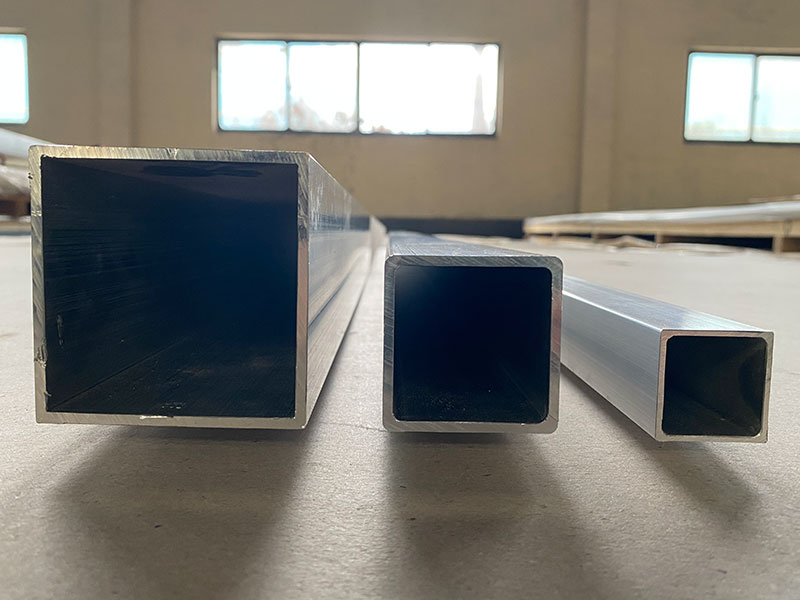

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details

Leave a Message