6061 Marine Aluminum Tubes for Commercial Marine Vessels

In the realm of commercial marine construction, choosing the right materials is paramount. Among the best options, 6061 marine aluminum tubes have become the undeniable standard for their balance of strength, lightweight, and corrosion resistance.

What Sets 6061 Marine Aluminum Apart?

6061 marine aluminum possesses the right blend of attributes that make it perfect for marine construction:

- Lightweight Design: Lightweight materials are crucial in the marine sector, promoting fuel efficiency and speed.

- High Strength-to-Weight Ratio: With its tensile strength of up to 310 MPa (45,000 psi), 6061 offers high strength yet remains light, allowing for the construction of structures that support heavy loads.

- Excellent Corrosion Resistance: The alloy is naturally protected against corrosion by forming an oxide layer, which is particularly vital in saltwater environments.

- Good Workability & Weldability: The alloy's properties allow for easy fabrication and welding, ensuring that marine manufacturers can work efficiently without compromising quality.

Chemical Composition and Mechanical Properties of 6061 Marine Aluminum

6061 aluminum’s unique characteristics are enforced by its chemical composition. Here is a breakdown (in weight percent) according to Aluminum Association standards:

Implementation Standards: Safety Meets Functionality

6061 marine aluminum tubes engage highly critical international standards Language specifications precede their application. In marine vessel production, adherences to ASTM B221 and the American Bureau of Shipping (ABS) standards ensure the aircraft's safety and functionality.

ASTM B221: Establishes the specifications for aluminum and aluminum-alloy extruded bar, rod, tube, and profiles—the holy grail for ensuring structural integrity in commercial packs.

ABS Standards: Certifications from ABS include all crucial safety metrics, including corrosion allowances, testing methodologies for mechanical properties, ultimate tensile strength, and yield strength to combat real-world maritime stresses.

Tempering and Heat Treatment: Crafting the Allo-Trescent Shield

Alloys, especially 6061, involve tempering strategies refining their mechanical properties. The most notable tempers used are:

T6**

- Description: Solution heat-treated and artificially aged.

- Properties: Increased yield tensile strength; suited for components subjected to elevated stress imaging—think hull structures on commercial vessels.

T4**

- Description: Solution heat-treated but not aged.

- Properties: Provides better formability and welding characteristics boosting versatility during fabrication processes.

T5**

- Description: Cooled from an elevated temperature and artificially aged.

- Properties: Ensured for enhanced ductility, structured to handle unpredictable load applications that mariners frequently encounter.

Real-World Applications of 6061 Marine Aluminum Tubes

Whether you are facing rough seas or navigating complex waterways for commercial uses, the 6061 aluminum variety surfaces exorbitantly in many marine applications. Here are a few distinctive implementations:

Cats, Yachts, Small Boats: Removal of concentrated weight for standout maneuverability, enhancing recreational deep-sea fishing—with streetsfishing callbacks to family bridging ideals.

Commercial Ships: Fitting choice for hulls and structural systems, serving as an affordable yet high-caliber replacement for stainless or heavier problematic steel counterparts—it transports bulk properties more seamlessly.

Fabricated Parts: An ideal substance for winch EVT ladders, folding constructions, offering an essential aspect of protective coatings against resin shr Nevwhira clott down drafts.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

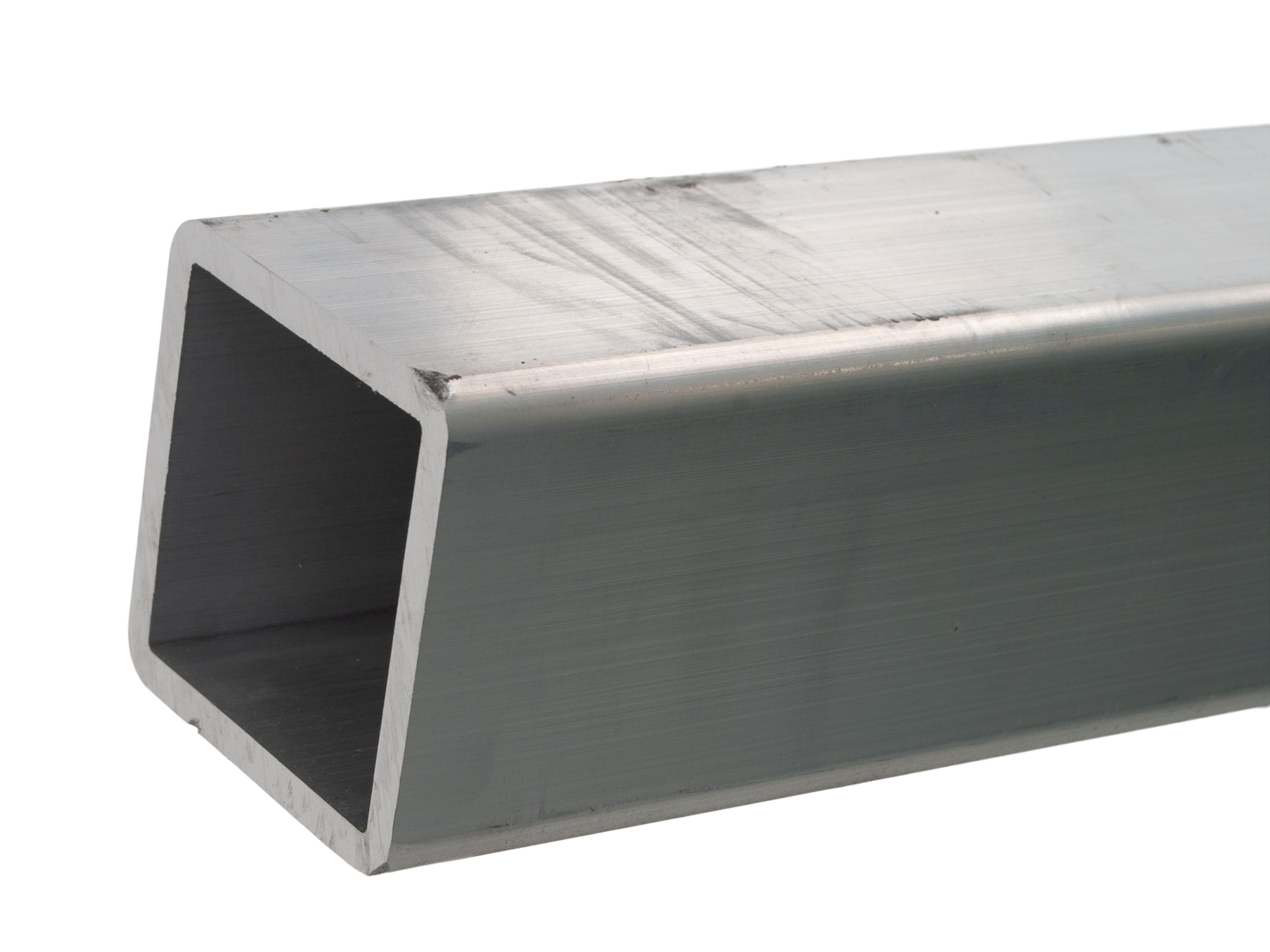

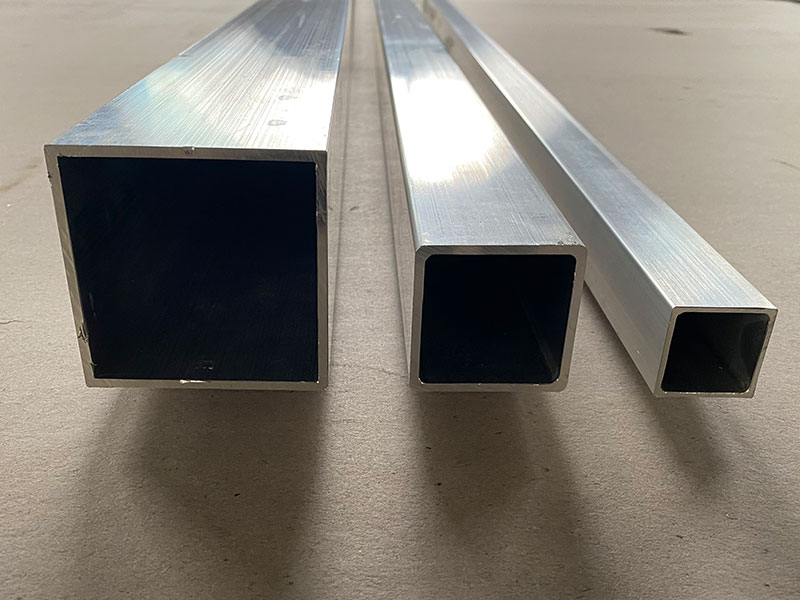

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

6061 Marine Aluminum Tubes for Custom Boat Frame Solutions

When it comes to constructing custom boat frames, marine-grade materials play a crucial role in ensuring longevity, safety, and performance. Among the vast selection of marine-grade metals.

View Details6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details6061 Marine Aluminum Tubes for Commercial Marine Vessels

In the realm of commercial marine construction, choosing the right materials is paramount. Among the best options, 6061 marine aluminum tubes have become the undeniable standard for their balance of strength, lightweight, and corrosion resistance.

View Details6061 Marine Aluminum Tubes for Marine Machinery Support Systems

6061 Marine Aluminum Tubes: Essential for Marine Machinery Support SystemsIn the complex machinery and construction of the marine industry, the materials crafted for durability and management play a pivotal role.

View Details6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View Details

Leave a Message