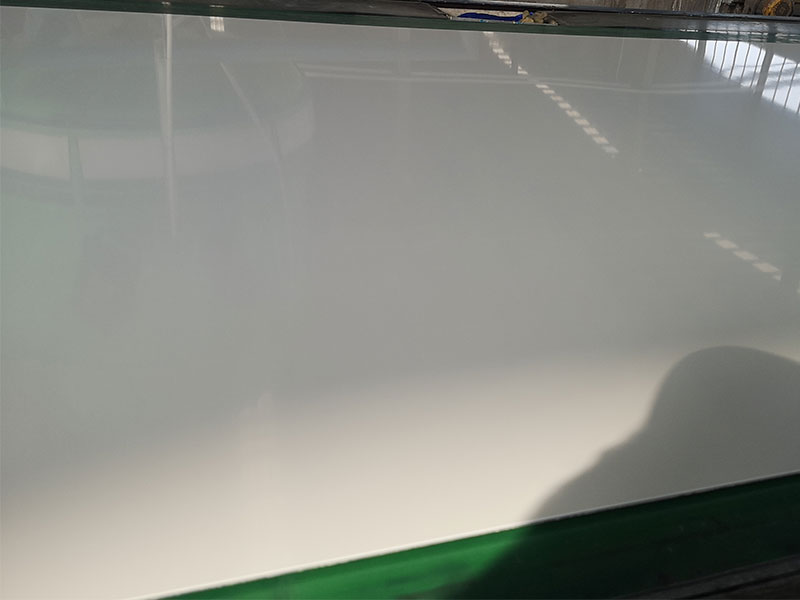

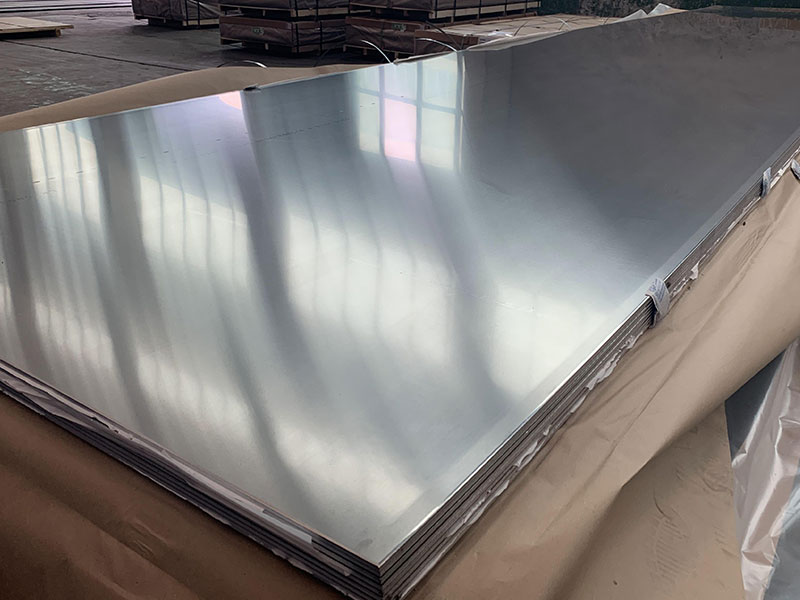

Marine aluminum alloy plates

Marine aluminum alloy plates represent a vital material cornerstone in the maritime industry, deserving a focused discussion on their distinct functions, wide applications, and intricate technical specifications. Unlike traditional steel counterparts, marine aluminum alloys provide a unique balance of weight, strength, and corrosion resistance tailored to the challenging marine environment.

At their core, marine aluminum alloy plates serve multiple functions beyond simple structural support in watercraft. Their lightweight nature significantly reduces overall vessel weight, leading to enhanced speed, fuel efficiency, and payload capacity. Importantly, their intrinsic corrosion resistance, largely derived from both alloy composition and surface properties, ensures prolonged lifespan in saltwater environments, where chemical degradation would otherwise impair performance.

Functionally, these plates must withstand not only static loads but also dynamic forces due to waves, wind, and onboard vibration, requiring alloys with excellent toughness and fatigue resistance. The nuanced mechanical behavior of these plates is influenced by both the base chemistry and subsequent heat treatment or tempering processes, giving engineers tools to tailor properties to specific marine applications.

Applications: More than Just Hull Construction

While often associated with hull plating, marine aluminum alloy plates extend their uses far beyond the ship’s outer shell:

- Deck Houses and Superstructures: Their reduced weight mitigates top-heaviness, improving vessel stability.

- High-Speed Ferries and Patrol Boats: Enable fast accelerations and improved maneuverability owing to lightweight strength.

- Floating Platforms: Resist corrosion effectively, ensuring structural integrity on extended offshore installations.

- Bridges and Coastal Infrastructure: Structural aluminum alloys counteract marine atmospheric corrosion, reducing maintenance.

Technical Characteristics and Implementation Standards

Common Alloys and Parameters

Maritime specifications typically adopt the 5xxx series marine-grade aluminum alloys, notably alloys like 5083, 5454, and 5086, owing to their combination of strength and seawater resistance.

| Alloy | Typical Chemical Composition (wt%) | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| 5083 | Mg 4.0–4.9, Mn 0.4, Cr 0.05 | 2.66 | 290-350 | 145-230 | 12-18 |

| 5454 | Mg 2.7-3.3, Mn 0.25-0.8 | 2.67 | 275-335 | 145-210 | 11-12 |

| 5086 | Mg 3.5–4.5, Mn ~0.4, Cr 0.05 | 2.66 | 317-350 | 221-275 | 10-16 |

Alloy Temper and Heat Treatment Conditions

Marine aluminum alloy mechanical performance hinges on temper designation. Common temper conditions include:

- H116: Strain hardened and partially annealed, best suited for marine applications requiring highest corrosion resistance.

- H321: Stabilized for thermal exposure, ensuring preservation of properties after welding.

- H32: Solution heat treated and cold worked to moderate strength with enhanced formability.

Tempering chiefly balances tensile strength and corrosion resistance, avoiding conditions that encourage sensitization of grain boundaries and intergranular corrosion.

Implementation Standards

Rigorous certification in conformity with international maritime codes ensures reliability of marine aluminum plates. standards include:

- ABS (American Bureau of Shipping): Provides classification and strength requirements for shipbuilding plates.

- DNV GL (Germanischer Lloyd): Sets criteria on chemistry limits and mechanical efficiency.

- ISO 6362-3: Governs discovery and caratteristiche dei semilavorati in leghe comunitarie specific for marine applications.

- JIS H 4100 (Japan Industrial Standards): Offers precise chemical composition and mechanical property codifications.

Producers leverage carefully controlled smelting, rolling, and quenching sequences under stringent QC parameters to comply fully and supply consistent marine-grade products.

Viewed through a nuanced technical lens, marine aluminum alloy plates transcend their initial conception as metallic sheets, evolving into engineered composites that mediate mechanical demands, corrosion challenges, and application-specific integration. Their finely tunable chemical markers and thermal conditioning afford modern naval architecture unparalleled flexibility and dependability.

For vessel OEMs, platform constructors, and engineers venturing into the evolving marine frontiers, mastering the properties, temper designations, and regulatory frameworks of marine aluminum alloy plates offers tangible advantages—lighter, safer, more durable constructions poised for the seas ahead.

Related Products

Marine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsRelated Blog

7075 auminum marine plates hard aluminum plates

7075 aluminum marine plates are high-strength, durable, and corrosion-resistant aluminum alloy plates predominantly used in demanding marine environments. Known for their mechanical properties.

View Details5083 H116 marine grade aluminum alloy sheet plate

Superior corrosion resistance and high strength of 5083 H116 marine grade aluminum alloy sheet plate. Ideal for shipbuilding and marine structures, this alloy ensures durability in harsh sea conditions with excellent weldability and excellent workability.

View DetailsAluminum Alloy Plate 5083 H24 for Marine

OverviewAluminum Alloy Plate 5083 H24 is a high-performance material widely favored in marine engineering due to its excellent combination of high strength, exceptional corrosion resistance, and good weldability.

View DetailsMarine aluminum alloy plates

Marine aluminum alloy plates represent a vital material cornerstone in the maritime industry, deserving a focused discussion on their distinct functions, wide applications, and intricate technical specifications.

View Details5052 H34 Aluminum Plate for Boat

When it comes to marine applications, specifically boat building and repair, selecting the right aluminum material is critical for long-lasting performance, corrosion resistance, and structural integrity.

View Details7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.

View Details

Leave a Message