Marine Aluminum Angles for Offshore Boat Frame Reinforcement

In the realm of marine engineering, the design and construction of offshore boat frames are crucial for performance, safety, and longevity. Among the various materials available, Marine aluminum angles is know as a preferred choice for frame reinforcement, particularly because of their excellent strength-to-weight ratio, resistance to corrosion, and ease of fabrication. This comprehensive guide will analyze the dynamic role of Marine aluminum angles, emphasizing their technical parameters, standards, and unique chemical properties that make them indispensable for any maritime application.

Unveiling Marine aluminum angles

What Are Marine aluminum angles?

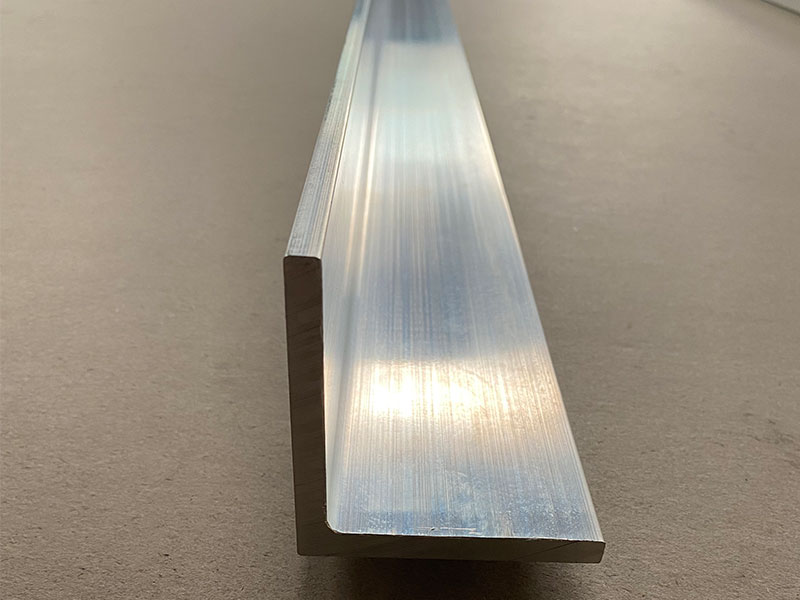

Marine aluminum angles are L-shaped extrusion pieces crafted from aluminum alloys specifically designed for marine environments. These angles play a pivotal role in providing structural support since they are an integral part of the frame in offshore boats, stiffening whole sections while preventing excessive torsion and bowing.

Why Choose Marine Aluminum?

Several advantages make Marine aluminum angles the superior choice:

- Corrosion Resistance: Marine-grade aluminum alloys are engineered to withstand various environmental tacky conditions, including saltwater and humidity.

- Lightweight Yet Strong: The geometry of aluminum angles offers high rigidity with significantly less weight than steel, improving vessel performance.

- Cost-Effective: With durability factors high on the list, many operators find maintenance and long-term costs of aluminum significantly lower than traditional steel over time.

Technical Parameters of Marine aluminum angles

In the welding, structural, and load arrangements that highlight the potential of marine aluminum, the right alloy and tempering condition cannot be overlooked. Below is a synthesis of performance parameters essential for constructing durable offshore boats.

1. Material Properties and Parameters Table

| Parameter | Alloy | Temper | Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|

| 6061 Aluminum | 6061-T6 | Standard | 241 | 276 | 12 | 2.70 |

| 5083 Marine Grade | 5083-H116 | Standard | 210 | 240 | 14 | 2.66 |

| 5656 Aerospace Grade | 5656-H112 | Standards | 185 | 250 | 12 | 2.73 |

2. Implementation Standards

To ensure the highest quality, Marine aluminum angles must adhere to internationally recognized frameworks:

- American Welding Society (AWS) Standards: Crucial for welding protocols that ensure strength and minimize defects.

- Marine Standards ISO 3834: These set comprehensive quality assurances for welding accuracy and practices specific to marine environments.

- DNV GL Type Approval: Indispensable for marine aluminum products; this ensures compliance with Lloyd's Register for material use in shipbuilding.

Tip: When fabricating bow/deck framing, ensuring compliant segment defects/grid structures will be minimized.

Alloy Tempering and Chemical Properties

Alloy Tempering Explained

Alloy consortia can use altering tempers (T4, T6, H116) based on designer specifications to define mechanical properties after production-content features:

- T4: Solution heat-treated and naturally aged. This produces equilibrium defenses, commonly implemented in welded base sections for rigidity.

- T6: Heat treated for premium adjustable outcomes ideal for heavy impact circumstances.

- H116: Optimized to counter ocean tidal shock stress; ideally suited for rigid supports working load of taut seams.

Chemical Composition Breakdown

Marine aluminum must possess the inherent ability to withstand environmental wear. the innate chemical configurations become options for efficacy:

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Others |

|---|---|---|---|---|---|---|---|---|

| 6061 | ≤ 0.40 | ≤ 0.70 | 0.15-0.40 | 0.15-0.80 | 0.80-1.20 | ≤ 0.25 | ≤ 0.15 | – |

| 5083 | ≤ 0.40 | ≤ 0.40 | - | 0.40-0.70 | 3.50-4.50 | ≤ 0.25 | ≤ 0.15 | – |

| 5656 | ≤ 0.70 | ≤ 0.15 | 0.15-0.20 | 0.04-0.30 | 0.25-0.70 | - | - | – |

Wrapping it Up

The principles of selecting Marine aluminum angles not only hinge on the frame’s rigidity and functionality, but spotlight innovative designs integral to performance considerations. Years of specialization when implementing marine-grade aluminum allow end-users steering vessels to ebb tides dynamically, maintain momentum ratios efficiently as they pasteurize developed designs aboard—each passing coast marking meritorious milestones directly impacting their journey.

Related Products

5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum channels

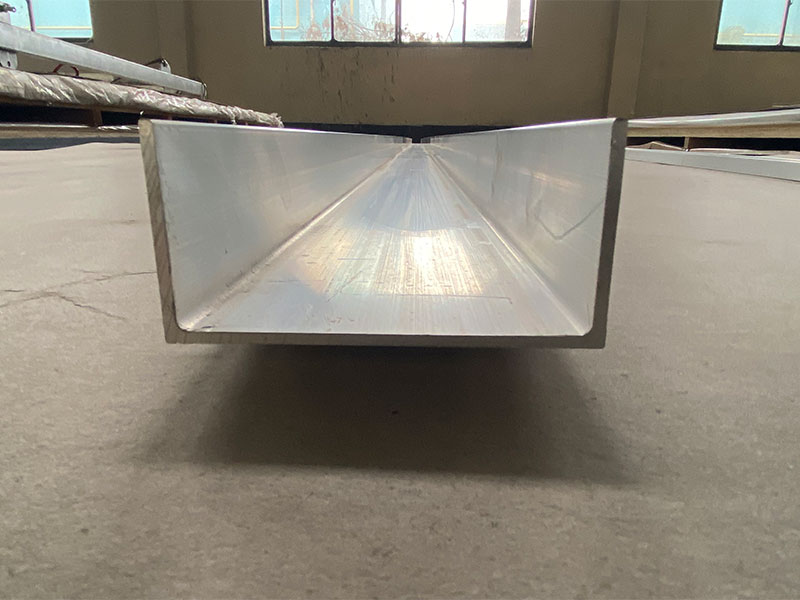

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details5083 Marine Aluminum Channels for Coastal Marine Engineering Projects

In the realm of coastal marine engineering, material selection is crucial for ensuring the durability, performance, and safety of structures exposed to harsh sea environments.

View DetailsMarine Aluminum Flat Bar for Boat Frame Reinforcement and Repair

Superior durability and corrosion resistance of Marine Aluminum Flat Bars, specifically engineered for boat frame reinforcement and repair. Learn about alloy compositions, mechanical properties, tempering conditions, and industry-compliant standards that

View Details6061 Marine Aluminum Round Bar for Custom Marine Vessel Parts

When it comes to marine vessel construction and maintenance, the materials chosen play an integral part in their functionality, longevity, and structural integrity.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View DetailsMarine Aluminum Round Bar for Saltwater Resistant Boat Design

When designing boats destined for saltwater environments, materials selection is paramount for ensuring long-lasting performance and reliable structural integrity.

View Details

Leave a Message