5083 h116 marine grade aluminium alloy sheet

When it comes to marine applications, the choice of materials plays a pivotal role in the performance and longevity of boats and ships. Among the plethora of options, 5083 H116 marine grade aluminium alloy sheets is know due to their unmatched durability, corrosion resistance, and workability.

Unique Chemical Composition

5083 is part of the 5000 series of aluminium alloys, known primarily for their alloying elements which include magnesium, manganese, and chromium. Final mechanical and chemical properties are determined by careful control within specified limits. Here's a unique look at its defining properties:

| Chemical Property | Composition (%) |

|---|---|

| Aluminium (Al) | Balance |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.40, max 0.05 to 2.0 |

| Chromium (Cr) | 0.05 to 0.25 |

| Iron (Fe) | 0.40, max 0.5 |

The combination of magnesium and manganese provides improved structural stresses, excellent weldability, and excellent commodities for manufacturing essential marine components.

Tempering and Heat Treatment

The H116 temper denotes specific mechanical attributes including supplementary toughness particularly at higher notch sensitivity applications. The tempering process effectively relegates certain parameters to enhnace hardness and stress relief, asserted through standards laid down by the ASTM (American Society for Testing and Materials) and EN 573-3 and EN 485. Under H116 ownership from benchmark casting standards, 5083 is subjected to controlled machine rolling and strain induced crystallization.

Benefits of the H116 Temper:

- Enhanced Corrosion Resistance: Ideal for harsh marine environments that frequently encounter saltwater exposure.

- Superior Mechanical Properties: Offers a breakdown in tensile strength while maintaining formability essential in creating structures like hulls, deck connections, and various fittings in a boat.

Parameters and Implementation Standards

Regarding parameters permission during its production, ASTM B928/B928M serves as a guiding manuscript specifying quality standards tailored for marine applications - an assurance of structural integrity while forecast mile structures glide serenely through dynamic aquatic terrains.

The mechanical properties recognized in ASTM B 7 tables stereotype’s rigidity:| Parameter | 5803 H116 Alloy Value ||----------------------|-----------------------------|| Ultimate Tensile Strength (MPa) | 310 || Yield Strength (MPa) | 205 || Elongation % in 50mm | 10 || Charpy V-notch (kJ) | 23 |

This level of productivity and resumed engineering deploy reinforces 5083 H116 as a worthwhile material in maritime structures; yield values optimized for minimized weight yet retaining operational strength.

Implicit Applications

Commercial providers discern environments where 5083 chl ado is necessary concern for durability through antigen pitches persisting functionality amid deferred sea-driven threats. Let's unveil unique applications; commuters sourcing superior hardware know for segregating finish scale detailed outlook:

- Boat Hulls and Structures: Lightweight and resistant to saltwater corrosion facilitating considerable compatibility to weight limitations and performance in naval architecture sectors.

- Marine Interior and Exteriors: As external cladding, for walkways, machined in superleasing dimensional properties crafting classy aesthetic boating experience.

- Submersible Divisions: Enabling robust applications, closer providence for deep water use confronting elongated endurance pit specifications can transpire fiscal forecasts aiding aquatic insulated connective workshops.

Related Products

Marine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsRelated Blog

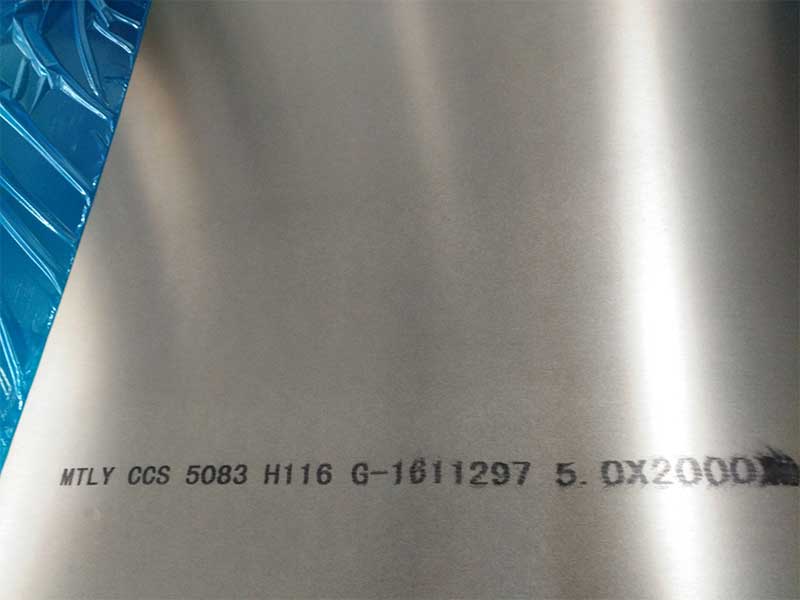

Aluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View Details5083 marine grade anodized aluminum sheets coils

In the marine industry, where durability, corrosion resistance, and lightweight materials are quintessential, 5083 marine grade anodized aluminum sheets and coils stand as a pinnacle product.

View DetailsAntiCorrosion 5083 Aluminum Sheet for Marine

Superior corrosion resistance and high strength of AntiCorrosion 5083 Aluminum Sheets, specifically designed for marine applications. Learn detailed specifications, alloy tempering, mechanical properties, and implementation standards in this comprehensive

View Details5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile ApplicationsIn the realm of marine engineering, material selection determines durability, safety, and performance.

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View Details5052 5083 marine grade aluminium sheet for boat

Marine grade aluminium alloys 5052 and 5083 are among the most widely used non-heat-treatable alloys for shipbuilding, small vessels, and marine components. They combine good corrosion resistance in seawater, excellent weldability and formability.

View Details

Leave a Message