Marine Aluminum Elbow Fittings for Powerboats and Yachts

Marine aluminum elbow fittings are an essential component in the construction and maintenance of powerboats and yachts. Used primarily in piping systems aboard marine vessels, these fittings provide reliable connections, offer corrosion resistance, and ensure optimal hydraulic flow in confined spaces.

Marine aluminum elbow fittings are specially designed connectors that change the direction of piping in marine plumbing layouts, typically shifting the flow at 45°, 90°, or custom angles. Manufactured using high-grade marine aluminum alloys, they generate excellent resistance to saltwater corrosion—critical for marine environments.

These elbow fittings are most commonly used in fuel, water, hydraulic, and cooling systems onboard powerboats and luxury yachts. The compatibility with aluminum piping and robust design make them favored over alternative materials such as stainless steel or plastic.

Core Functions and Benefits

- Directional Flow Control: Elbow fittings alter the piping route without restricting flow, a necessity in the confined space of vessels.

- Corrosion Resistance: Marine aluminum alloys effectively resist oxidation caused by saltwater exposure, thereby improving the longevity of plumbing systems.

- Lightweight Strength: Aluminum offers a strong yet lightweight option crucial for maintaining vessel balance and fuel efficiency.

- Ease of Installation: Designed to fit seamlessly within tight spaces, these fittings simplify assembly or repairs.

- Durability under Pressure: Suitable for a wide pressure range, guaranteeing effective service life across marine applications.

Common Applications in Powerboats and Yachts

- Fuel Lines: Ensuring leak-tight turning points that sustain explosive and high-pressure environments.

- Water and Drainage Systems: Supporting freshwater supply and grey/black water collection and routing without corrosion concerns.

- Hydraulic Systems: Facilitating fluid transfer vital to steering, winches, stabilizers, and other mechanical components.

- Cooling Systems: Redirecting cooling water used to maintain the engine and onboard machinery’s optimum temperature.

- Air Conditioning and Ventilation: Connection points for various cooling or ventilation flows on the vessel.

Technical Specifications of Marine Aluminum Elbow Fittings

The fittings discussed heretypically meet maritime industry implementation standards such as ABS (American Bureau of Shipping), DNV GL, ISO 9001 for quality management, and MIL-DTL-5541 or similar standards. These guide the alloy quality, dimensional precision, and performance parameters marine critical fittings.

| Parameter | Specification |

|---|---|

| Material Alloy | 5052-H32, 6061-T6, or 6082-T6 |

| Corrosion Resistance | Excellent in saltwater environments |

| Operating Pressure | Up to 10 MPa (1450 psi), depends on size |

| Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Standard Dimensions | 1/2 inch to 4 inch diameters |

| Connection Types | Butt weld, flanged, threaded (BSP/NPT) |

| Coating Options | Anodizing, powder coating (optional) |

| Weight | Lightweight relative to steel(corsponding sizes) |

Alloy Tempering Conditions and Mechanical Properties

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (Brinell) |

|---|---|---|---|---|---|

| 5052 | H32 | 228 | 138 | 12 | 75-85 |

| 6061 | T6 | 310 | 275 | 12 | 95-105 |

| 6082 | T6 | 310 | 260 | 10-12 | 90-100 |

Chemical Composition of Common Marine Aluminum Alloys

A precise chemical makeup generally defines how well the alloy resists marine and mechanical challenges.

| Element | 5052 (wt.%) | 6061 (wt.%) | 6082 (wt.%) |

|---|---|---|---|

| Aluminum | Balance | Balance | Balance |

| Magnesium | 2.2 - 2.8 | 0.8 - 1.2 | 0.6 - 1.2 |

| Silicon | 0.25 max | 0.4 - 0.8 | 0.7 - 1.3 |

| Iron | 0.4 max | 0.7 max | 0.5 max |

| Copper | 0.10 max | 0.15 - 0.4 | 0.1 max |

| Manganese | 0.1 - 0.5 | 0.15 max | 0.4 - 1.0 |

| Chromium | 0.15 max | 0.04 - 0.35 | 0.15 - 0.35 |

| Zinc | 0.10 max | 0.25 max | 0.20 max |

| Others | Trace | Trace | Trace |

Implementation and Installation Tips

For optimum reliability, installation must follow standard marine guidelines. Proper surface cleaning prior to welding or brazing, selection of correct tightness for threaded options, and avoiding galvanic corrosion by proper insulation or coating are standard procedures. Consideration for thermal expansion and vibration damping will enhance fitting lifespan onboard yachts and powerboats.

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

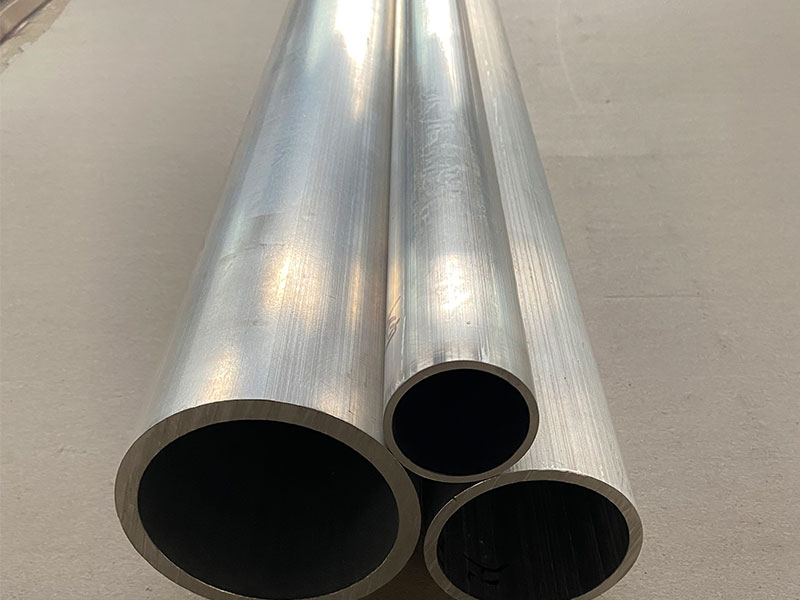

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

Aluminum Elbow for Ship Hot Water and Heating Systems

High-performance Aluminum Elbow designed for ship hot water and heating systems. Featuring optimal corrosion resistance, precise alloy specifications, and industry-standard tempering, this marine-grade fitting ensures durability and superior heat conducti

View Details90 Degree Marine Aluminum Elbow for Exhaust Systems

The 90 Degree Marine Aluminum Elbow for Exhaust Systems is a precision-formed bend designed specifically for marine engine and generator exhaust lines.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View DetailsMarine Grade Aluminum Pipe Elbow for Offshore Projects

Marine environments pose unique challenges—including corrosion, mechanical stress, and exposure to harsh elements—necessitating the use of specialized materials and components.

View DetailsHigh Quality Marine Aluminum Elbow for Boat Exhausts

High Quality Marine Aluminum Elbow for Boat Exhausts: Functions, Applications and Technical Insight Marine exhaust systems work in one of the harshest environments on a vessel.

View DetailsMarine Aluminum Elbow for Seawater Drainage Systems

Our high-performance Marine Aluminum Elbow designed specifically for seawater drainage systems, offering exceptional corrosion resistance, superior strength, and compatibility with marine-grade piping systems. Learn about its alloy composition, tempering,

View Details

Leave a Message